Accreditations

Filter by:

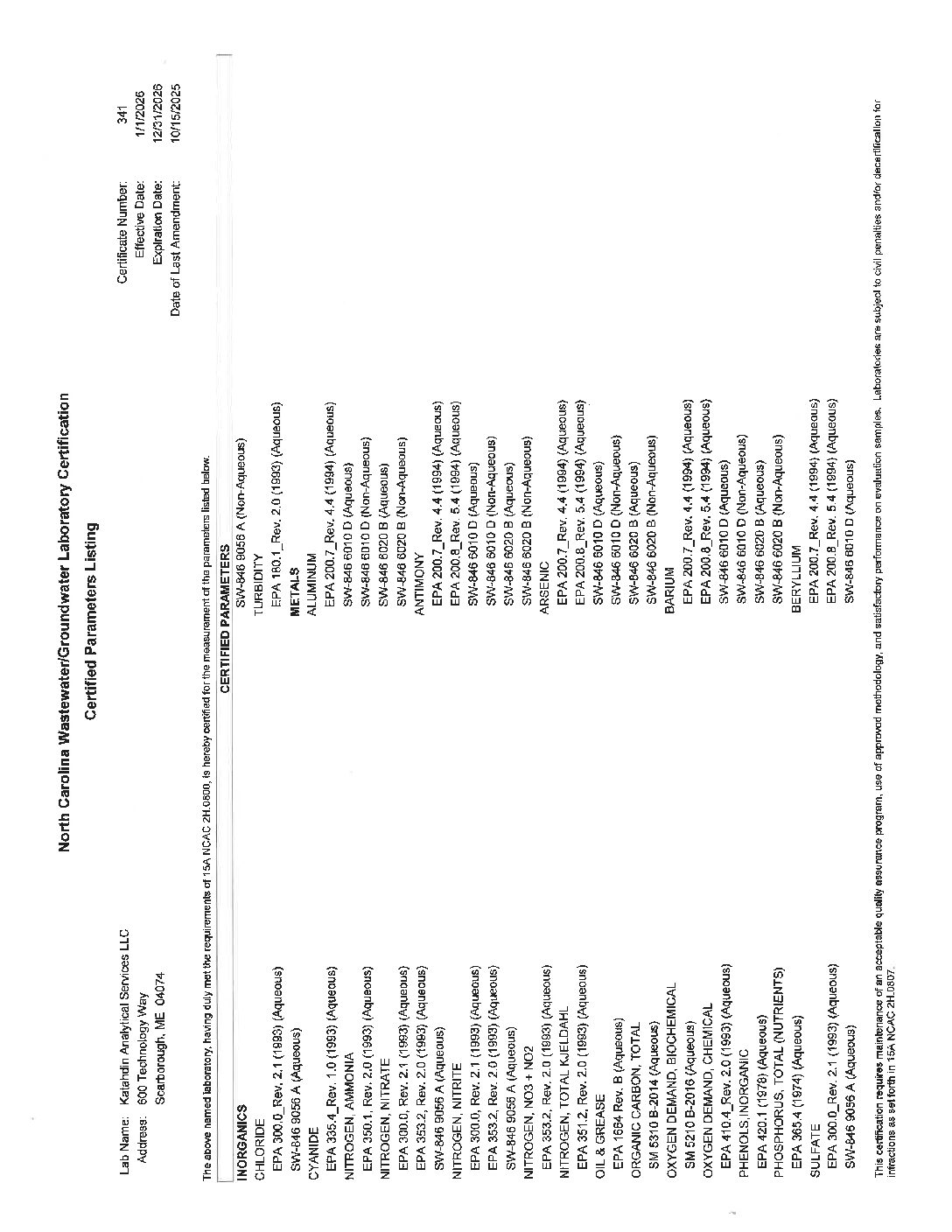

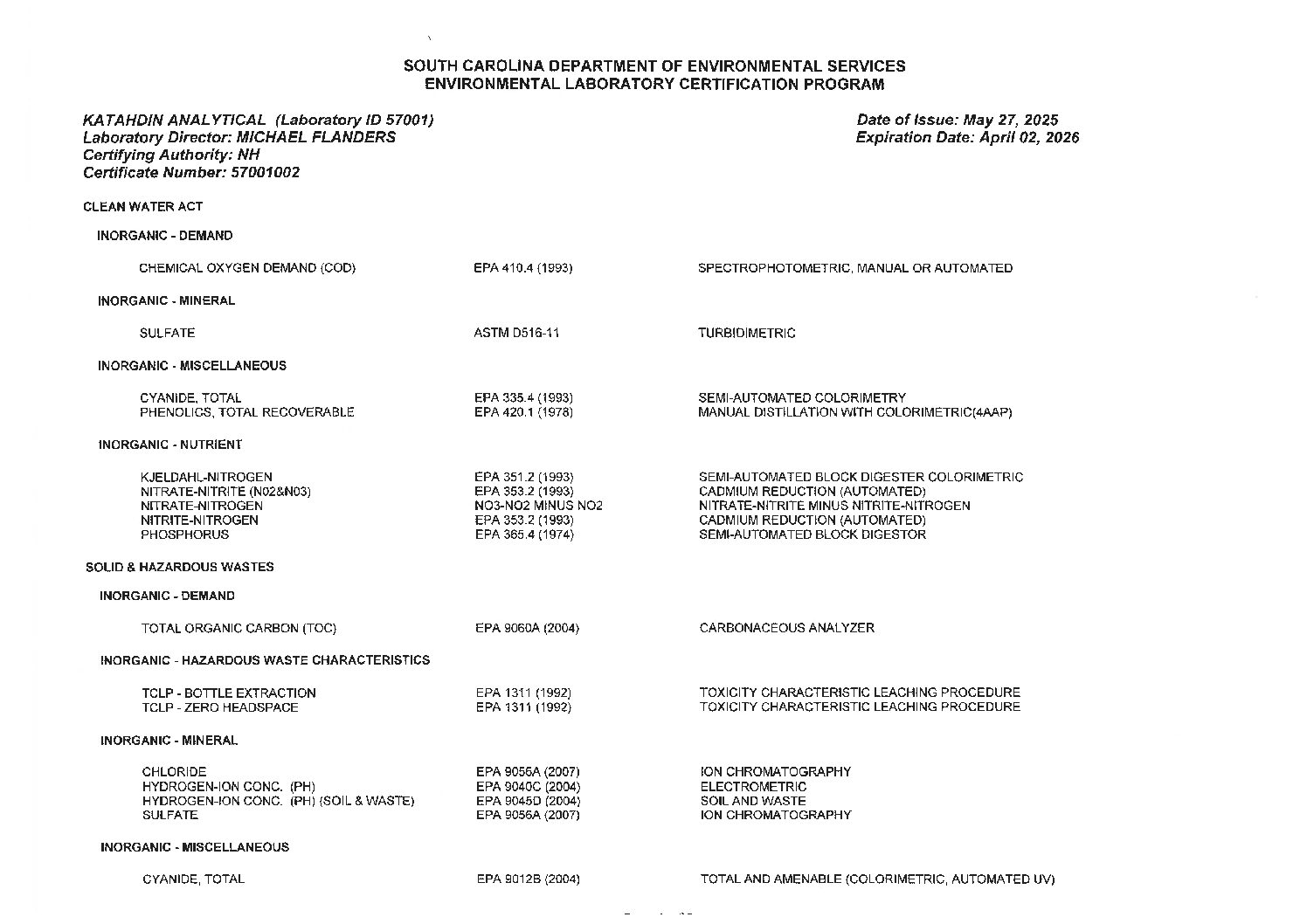

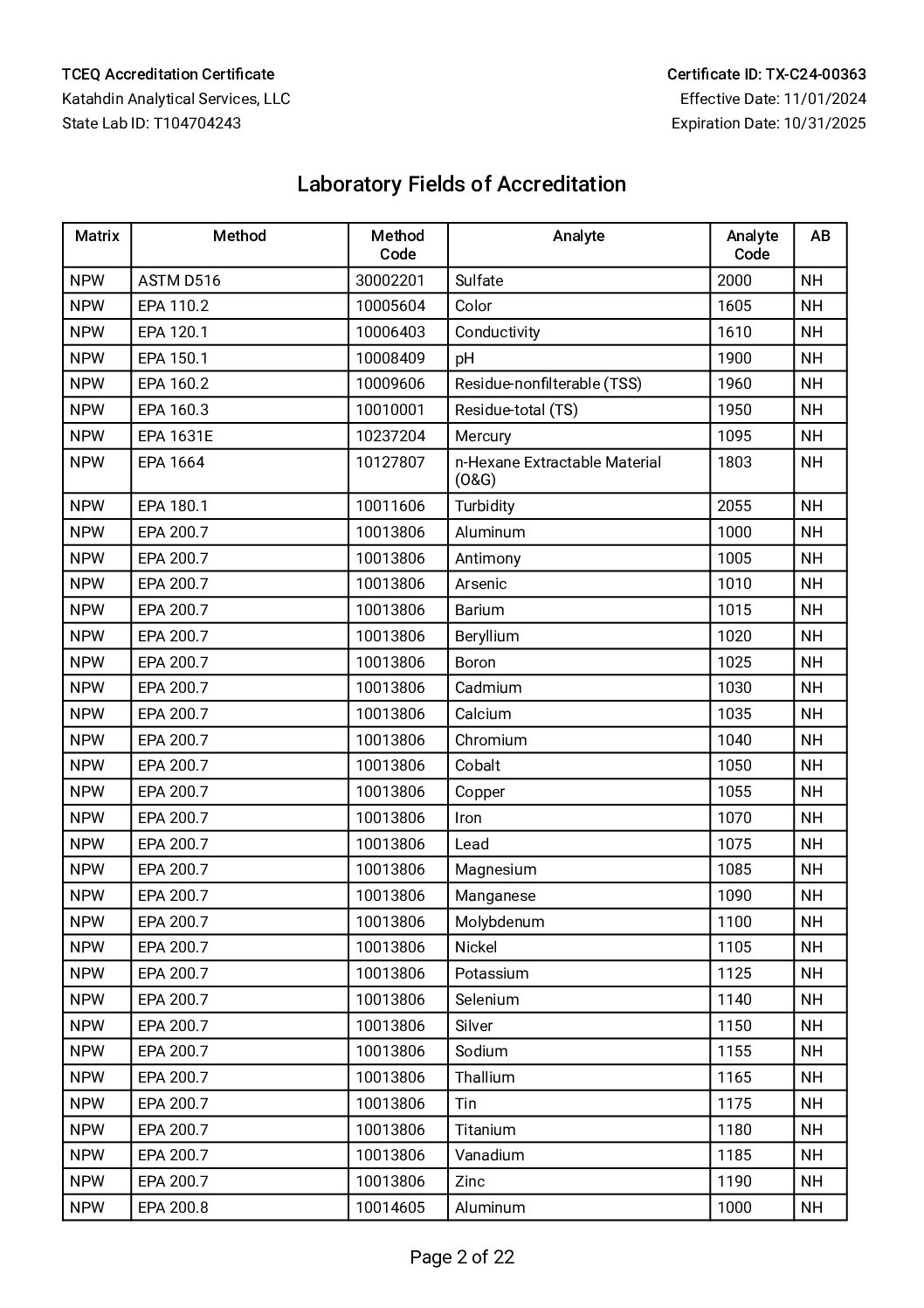

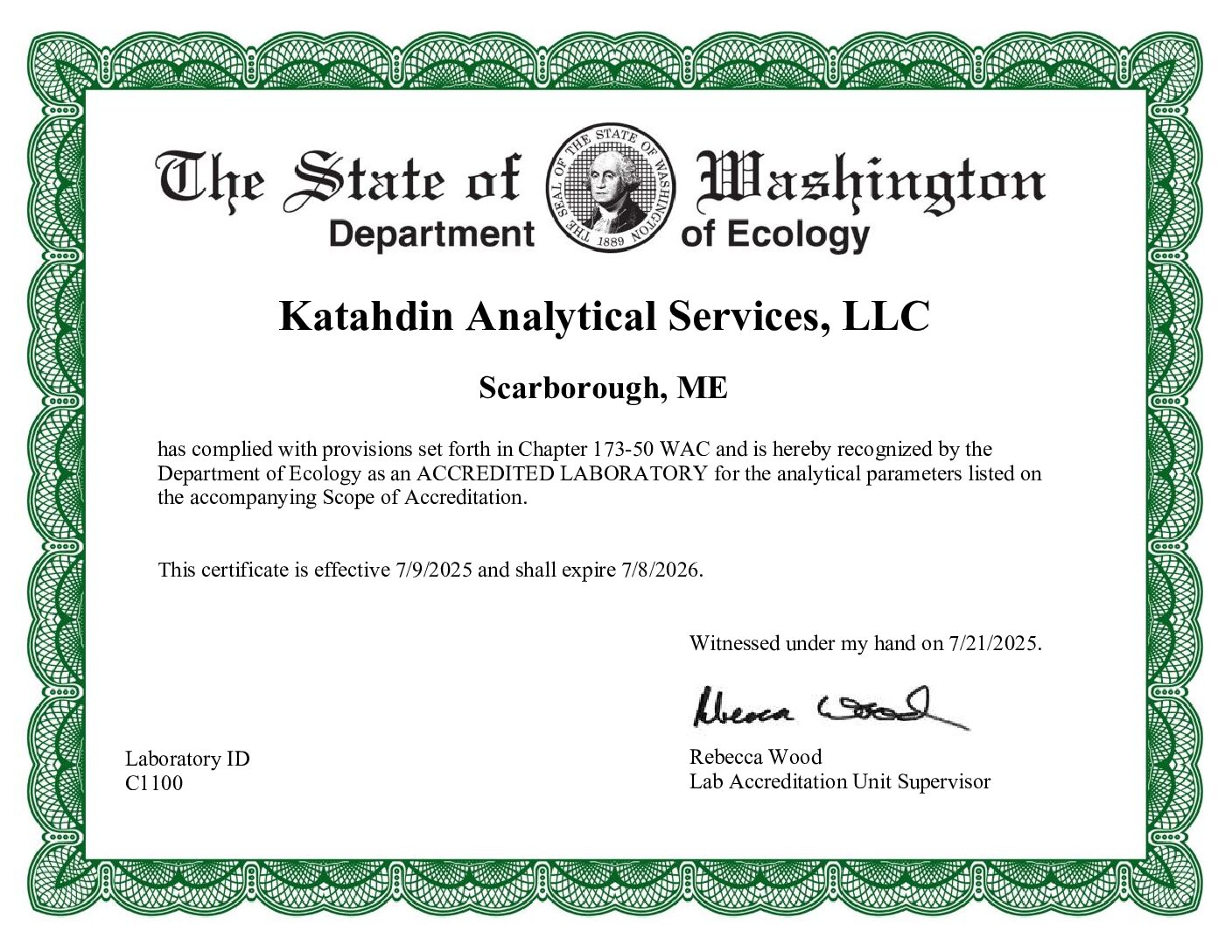

| Image | Location | Title | Body | Authority | Link | hf:doc_categories | hf:tax:dlp_document_state | hf:tax:dlp_document_location | hf:tax:dlp_document_accred-body | hf:tax:dlp_document_cert-authority |

|---|---|---|---|---|---|---|---|---|---|---|

| Scarborough, ME | SGS Scarborough Massachusetts Water Certificate | Drinking Water | Massachusetts Department of Environmental Protection (MADEP) | environmental-testing | massachusetts | scarborough-me | drinking-water | massachusetts-department-of-environmental-protection-madep | ||

| Scarborough, ME | SGS Scarborough Certificate of Accreditation – ISO-Food Testing | ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | environmental-testing | not-applicable | scarborough-me | iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

| Syracuse, NY | SGS Galson NYS DOH NELAC Environmental Analyses Solid and Hazardous Waste | TNI/NELAP | New York State Department of Health (NY DOH) | industrial-hygiene | new-york | syracuse-ny | tni-nelap | new-york-state-department-of-health-ny-doh | ||

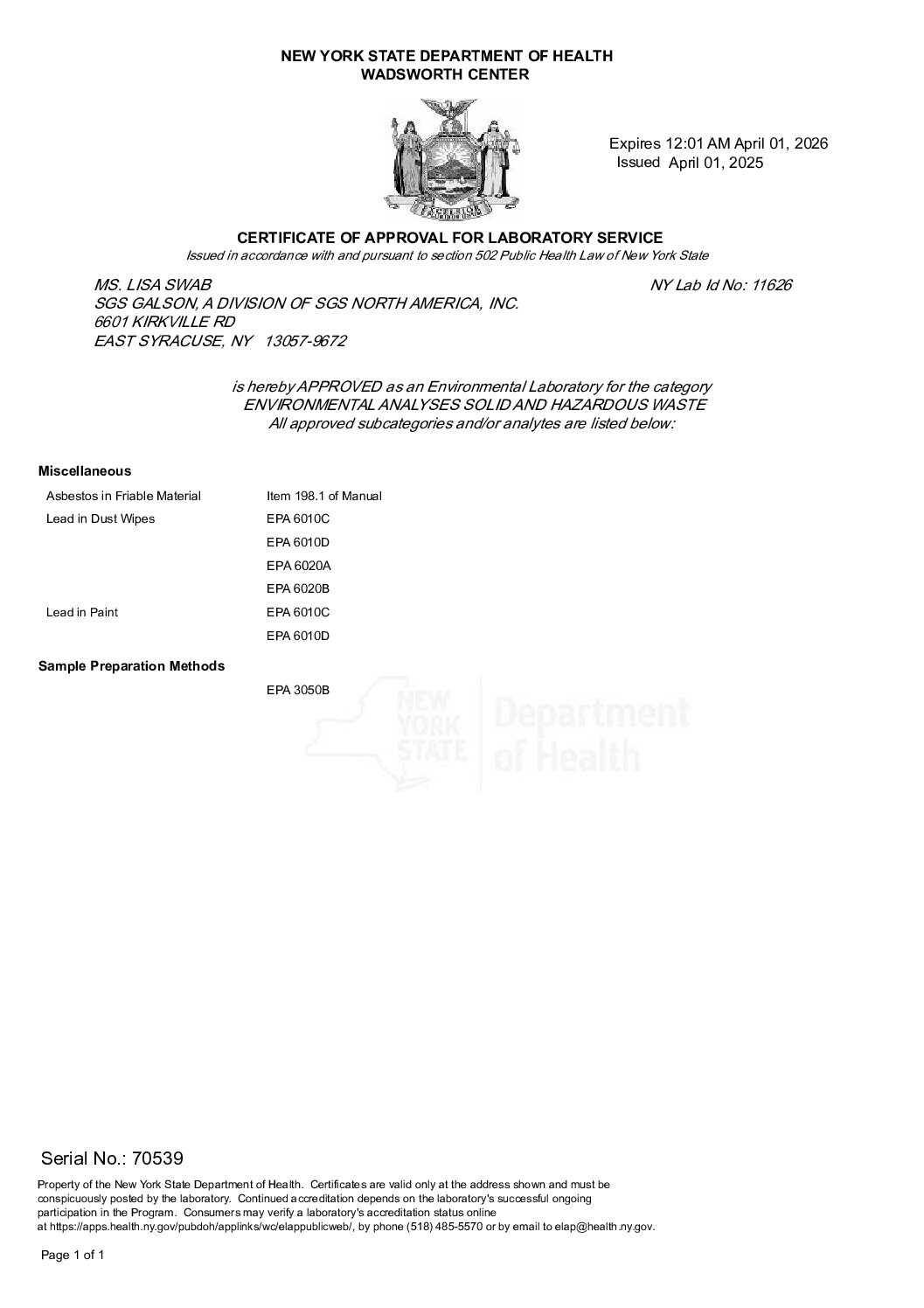

| Syracuse, NY | SGS Galson NYS DOH ELAP Environmental Analyses Solid and Hazardous Waste | TNI/NELAP | New York State Department of Health (NY DOH) | industrial-hygiene | new-york | syracuse-ny | tni-nelap | new-york-state-department-of-health-ny-doh | ||

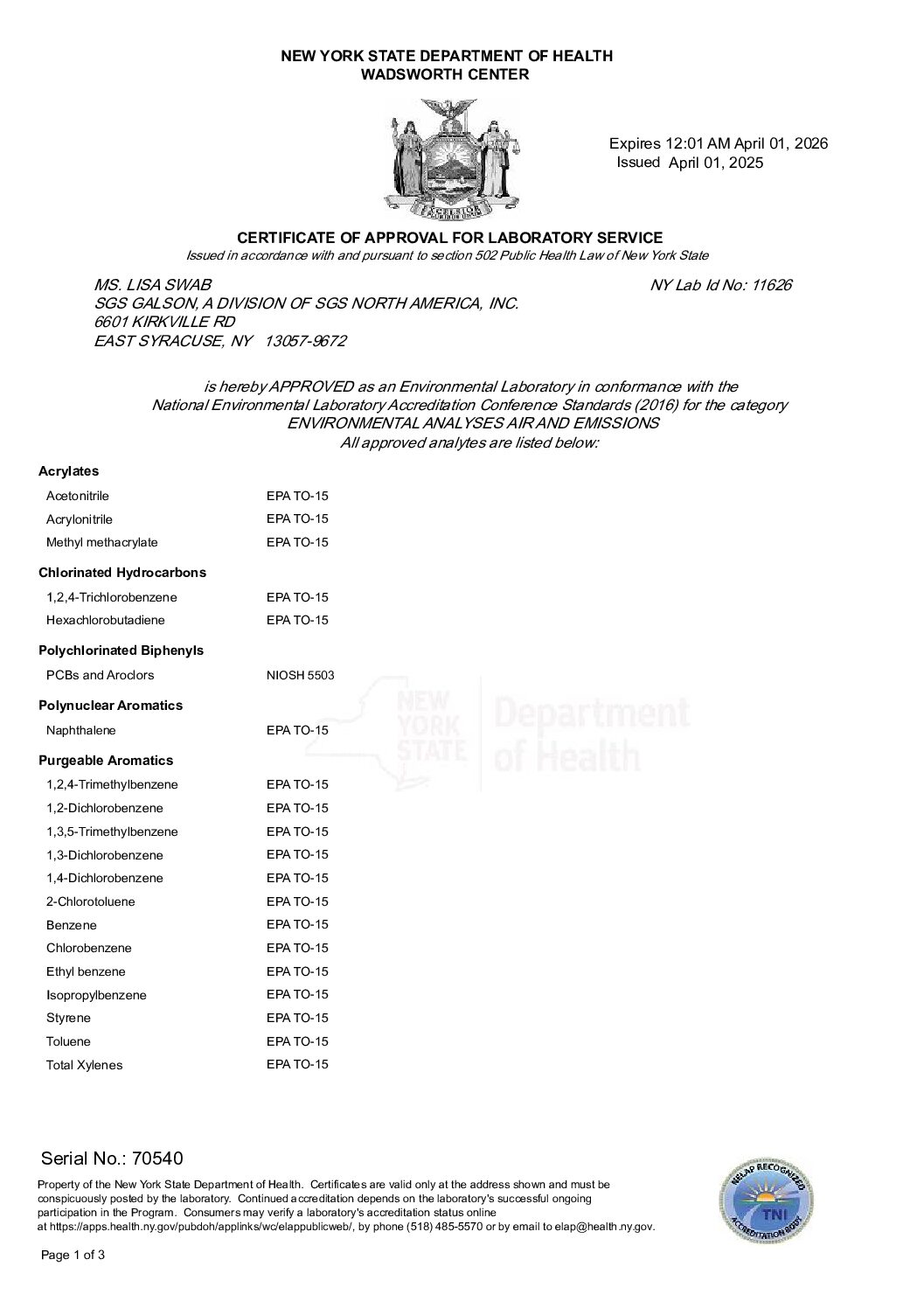

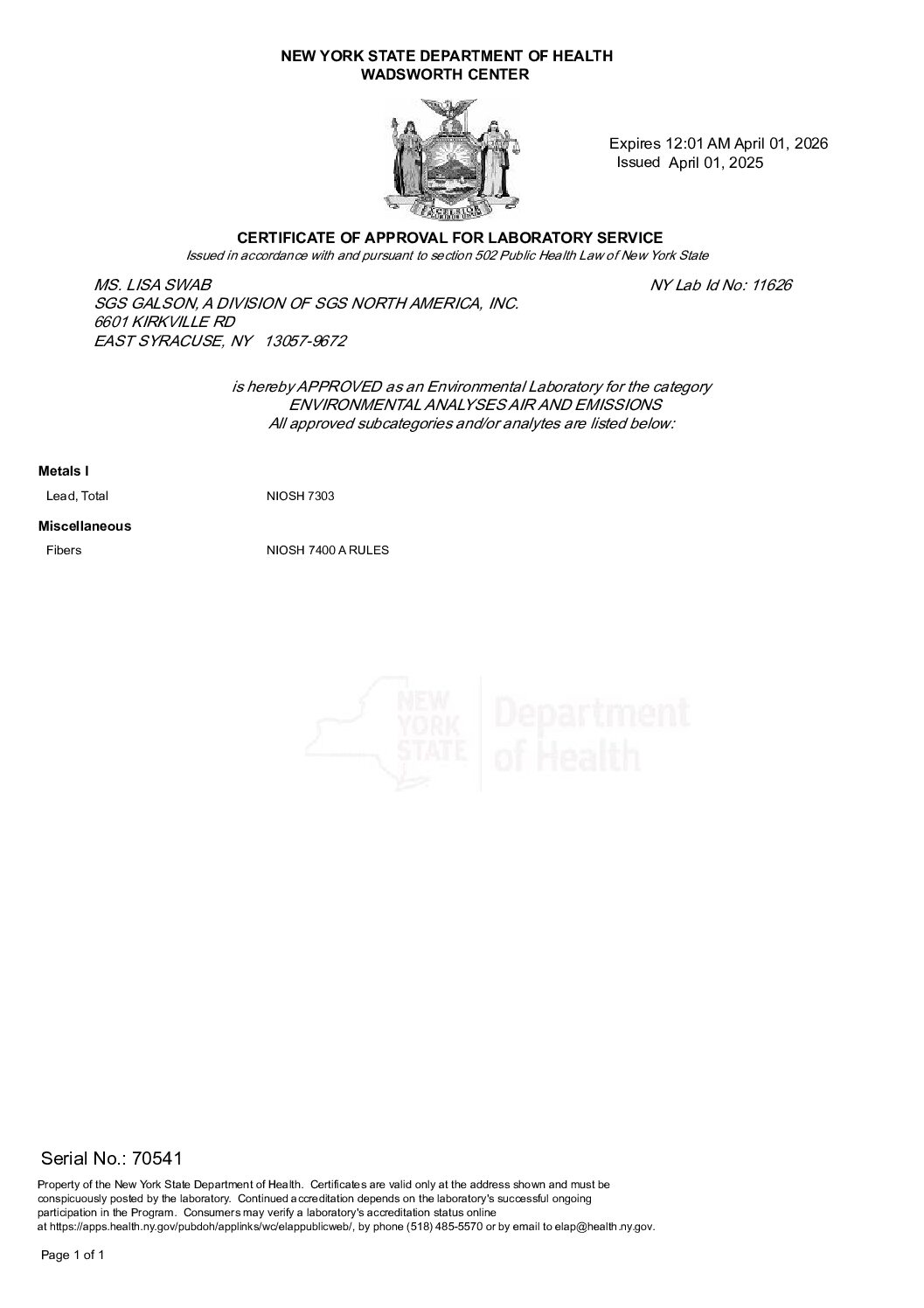

| Syracuse, NY | SGS Galson NYS DOH NELAC Environmental Analyses Air and Emissions | TNI/NELAP | New York State Department of Health (NY DOH) | industrial-hygiene | new-york | syracuse-ny | tni-nelap | new-york-state-department-of-health-ny-doh | ||

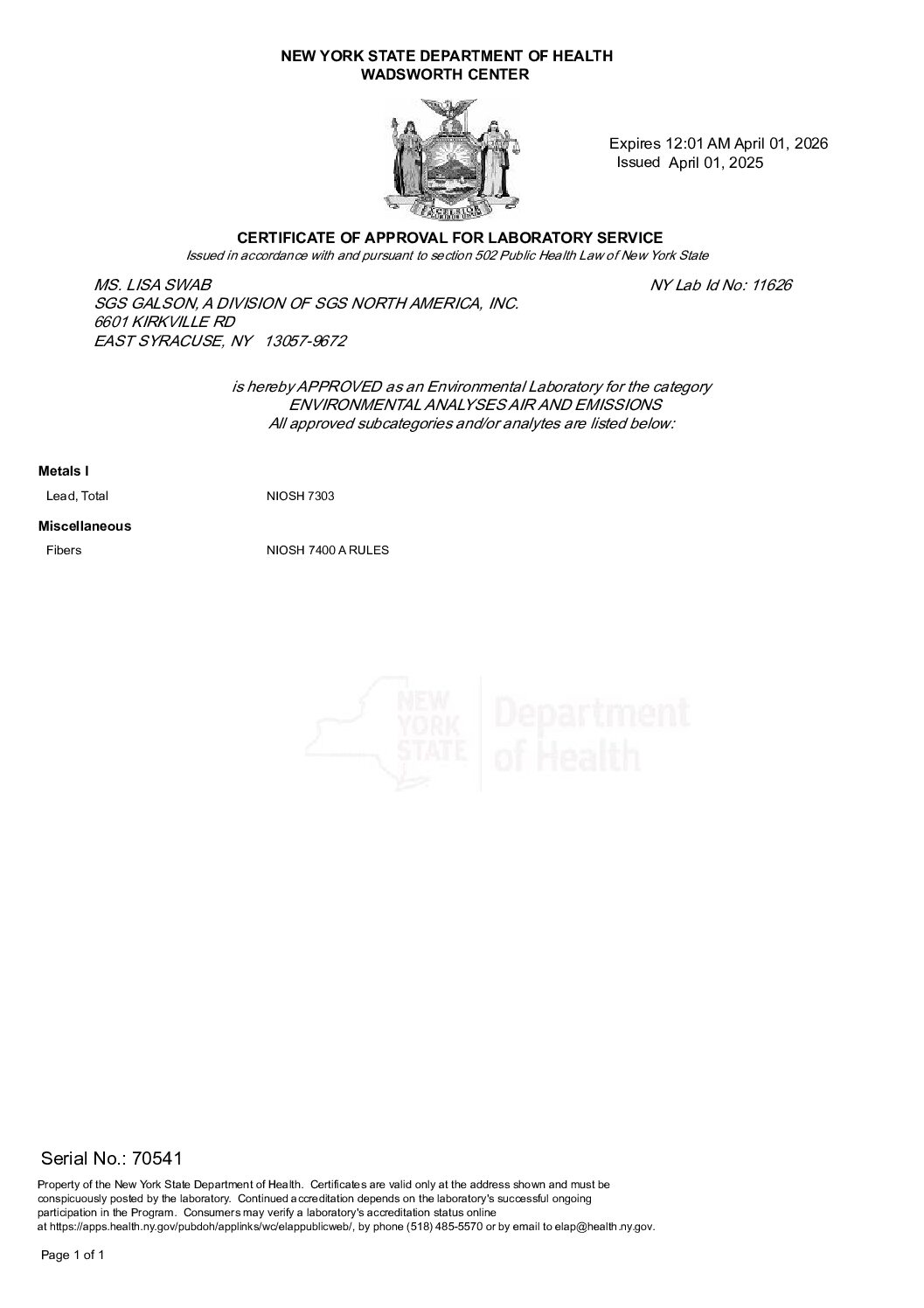

| Syracuse, NY | SGS Galson NYS DOH ELAP Environmental Analyses Air and Emissions | TNI/NELAP | New York State Department of Health (NY DOH) | industrial-hygiene | new-york | syracuse-ny | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Syracuse, NY | SGS Galson Louisiana DEQ LELAP | Non-NELAP States | Louisiana Department of Environmental Quality (LDEQ) | industrial-hygiene | louisiana | syracuse-ny | non-nelap-states | louisiana-department-of-environmental-quality-ldeq | ||

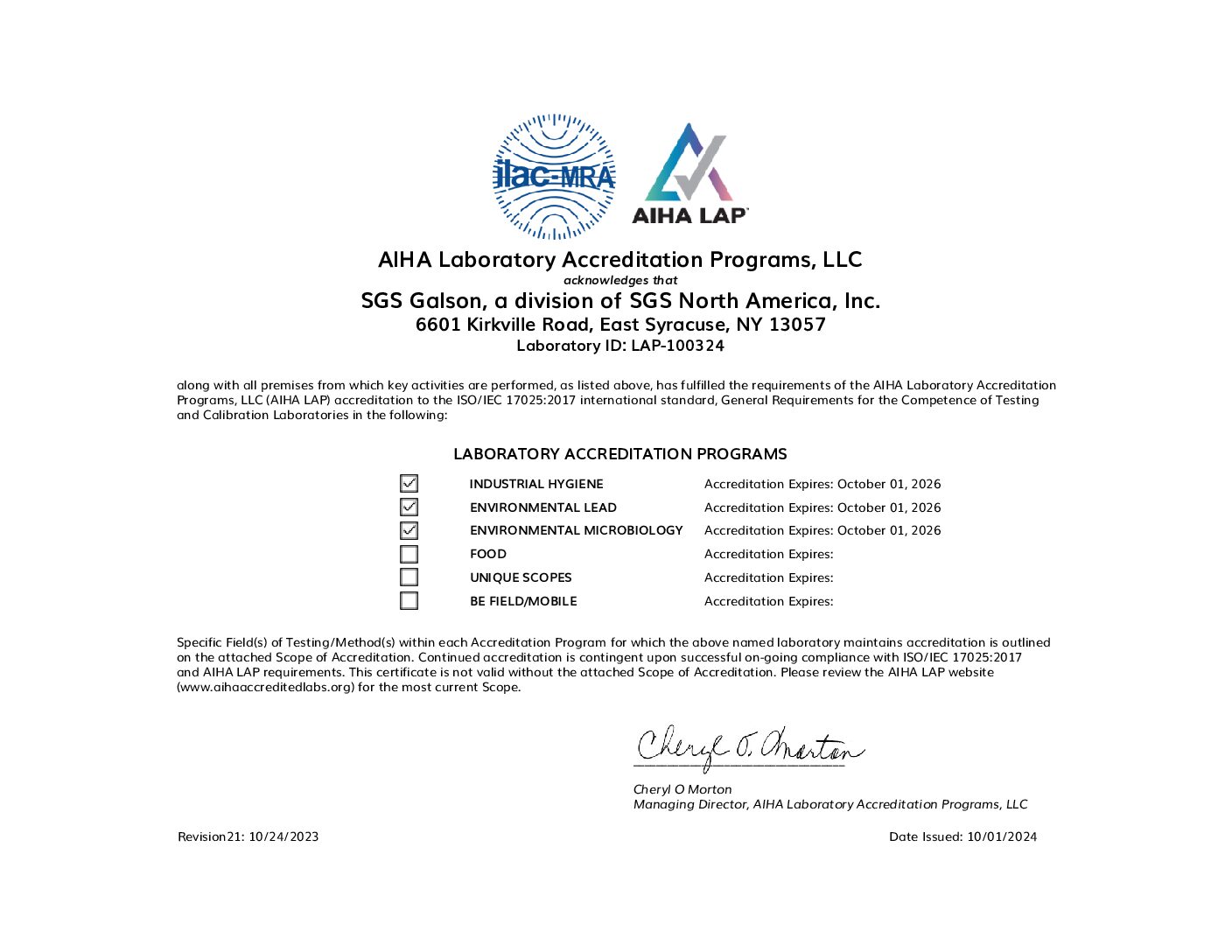

| Syracuse, NY | SGS Galson AIHA-LAP, LLC Scope of Accreditation ELLAP | AIHA | AIHA Laboratory Accreditation Program (AIHA LAP) | industrial-hygiene | syracuse-ny | aiha | aiha-laboratory-accreditation-program-aiha-lap | |||

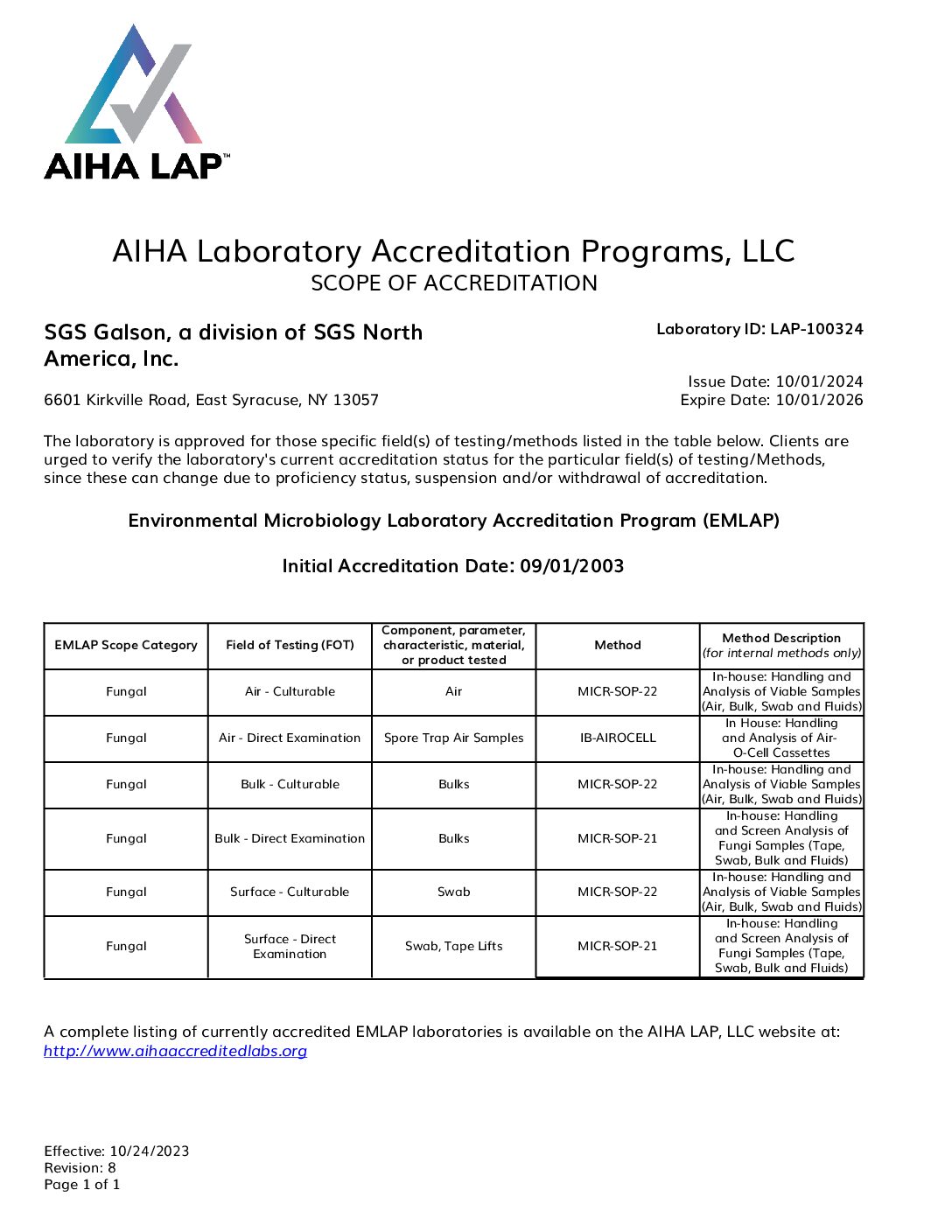

| Syracuse, NY | SGS Galson AIHA-LAP, LLC Scope of Accreditation EMLAP | AIHA | AIHA Laboratory Accreditation Program (AIHA LAP) | industrial-hygiene | syracuse-ny | aiha | aiha-laboratory-accreditation-program-aiha-lap | |||

| Syracuse, NY | SGS Galson AIHA-LAP, LLC Scope of Accreditation IHLAP | AIHA | AIHA Laboratory Accreditation Program (AIHA LAP) | industrial-hygiene | syracuse-ny | aiha | aiha-laboratory-accreditation-program-aiha-lap | |||

| Syracuse, NY | SGS Galson AIHA LAP Certificate | AIHA | AIHA Laboratory Accreditation Program (AIHA LAP) | industrial-hygiene | syracuse-ny | aiha | aiha-laboratory-accreditation-program-aiha-lap | |||

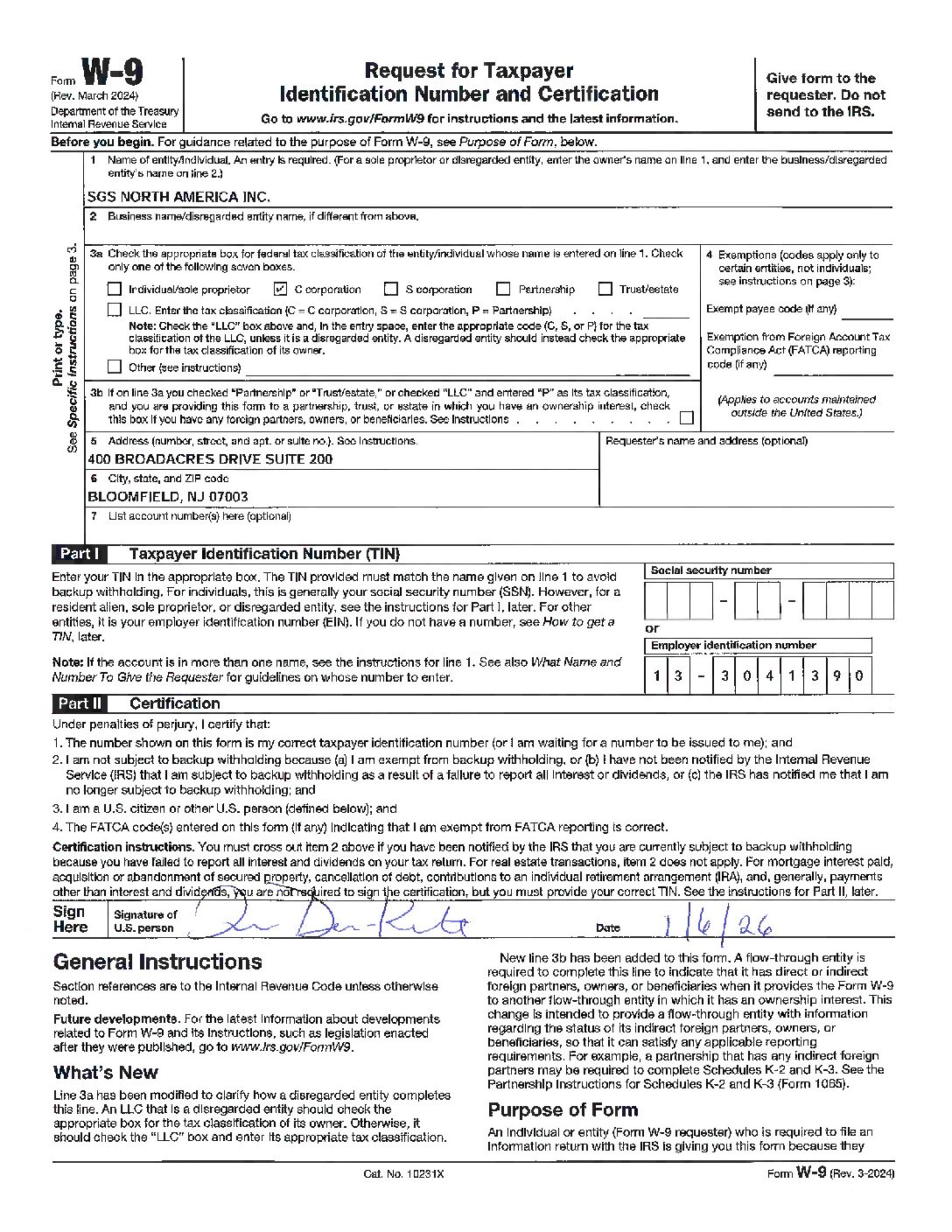

| SGS NA W-9 Form | industrial-hygiene | |||||||||

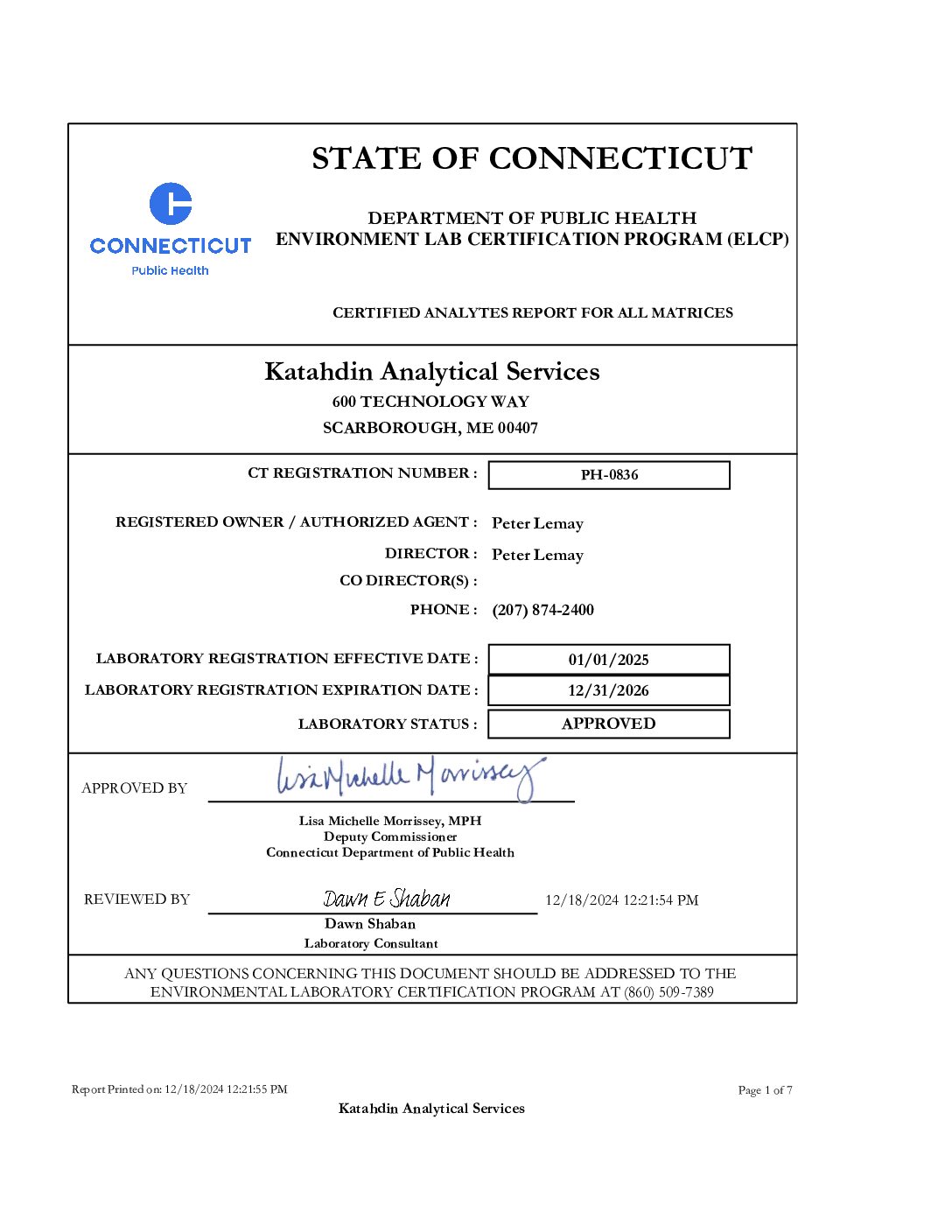

| Scarborough, ME | State of Connecticut, Department of Public Health | Drinking Water | Connecticut Department of Public Health (CT DPH) | environmental-testing | connecticut | scarborough-me | drinking-water | connecticut-department-of-public-health-ct-dph | ||

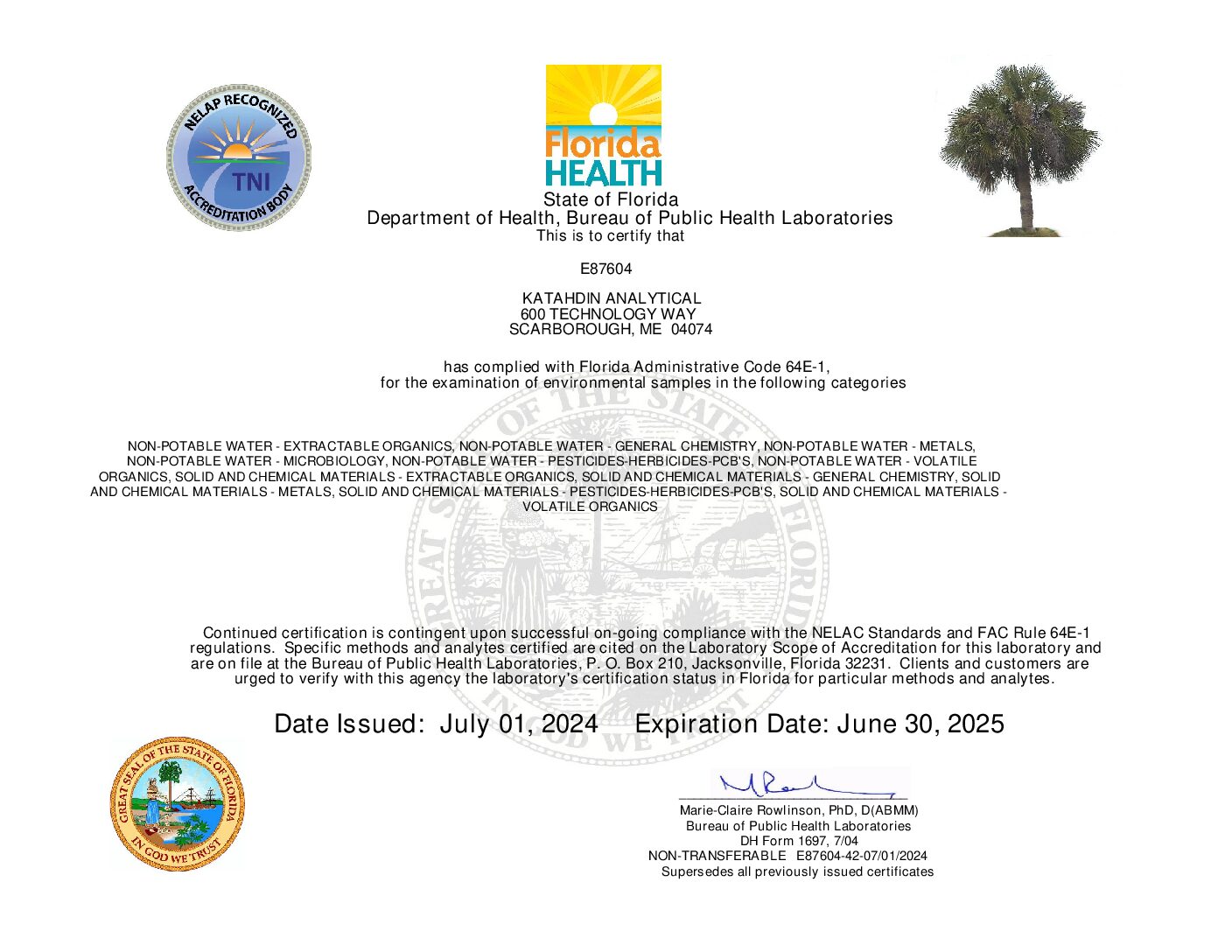

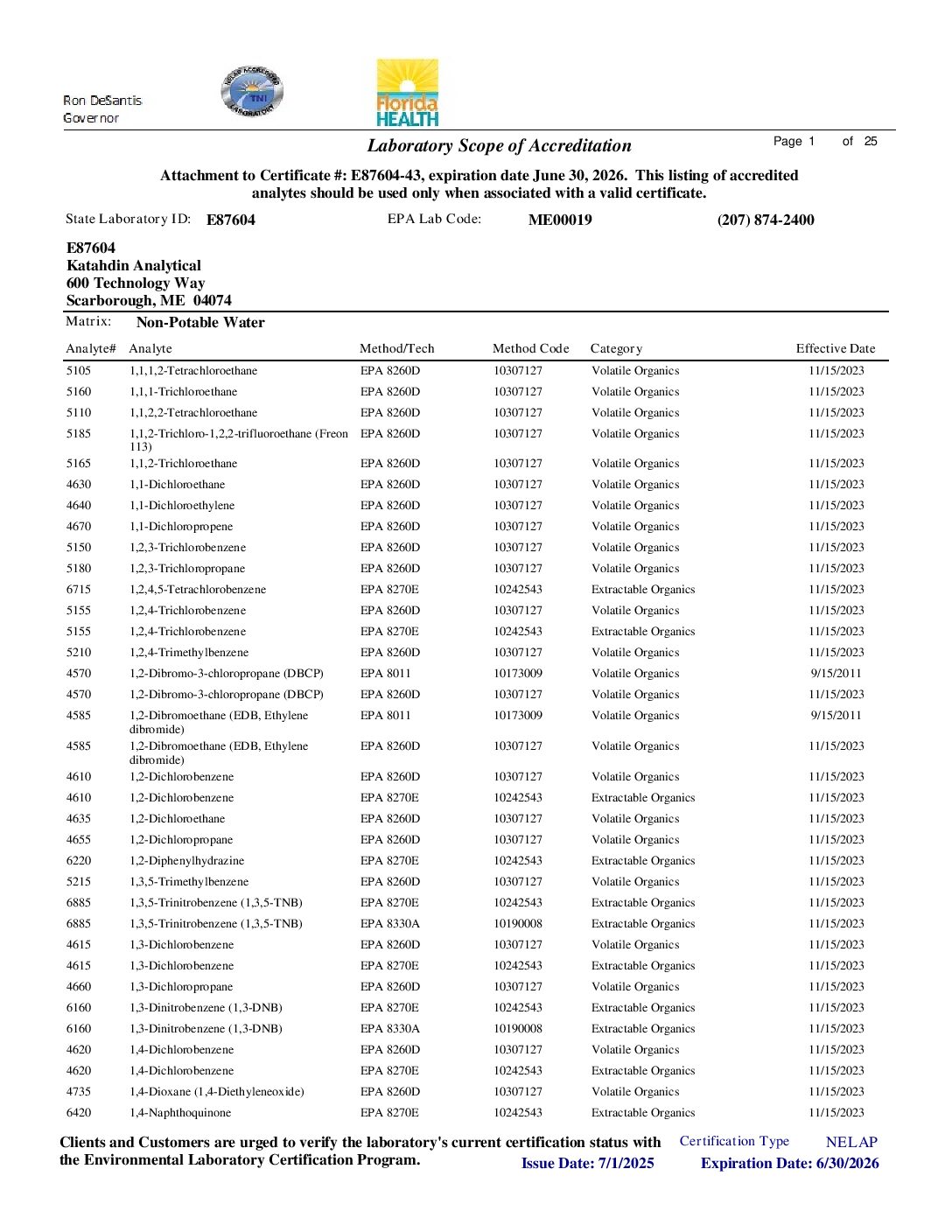

| Scarborough, ME | State of Florida, Department of Health | TNI/NELAP | Florida Department of Health (FL DOH) | environmental-testing | florida | scarborough-me | tni-nelap | florida-department-of-health-fl-doh | ||

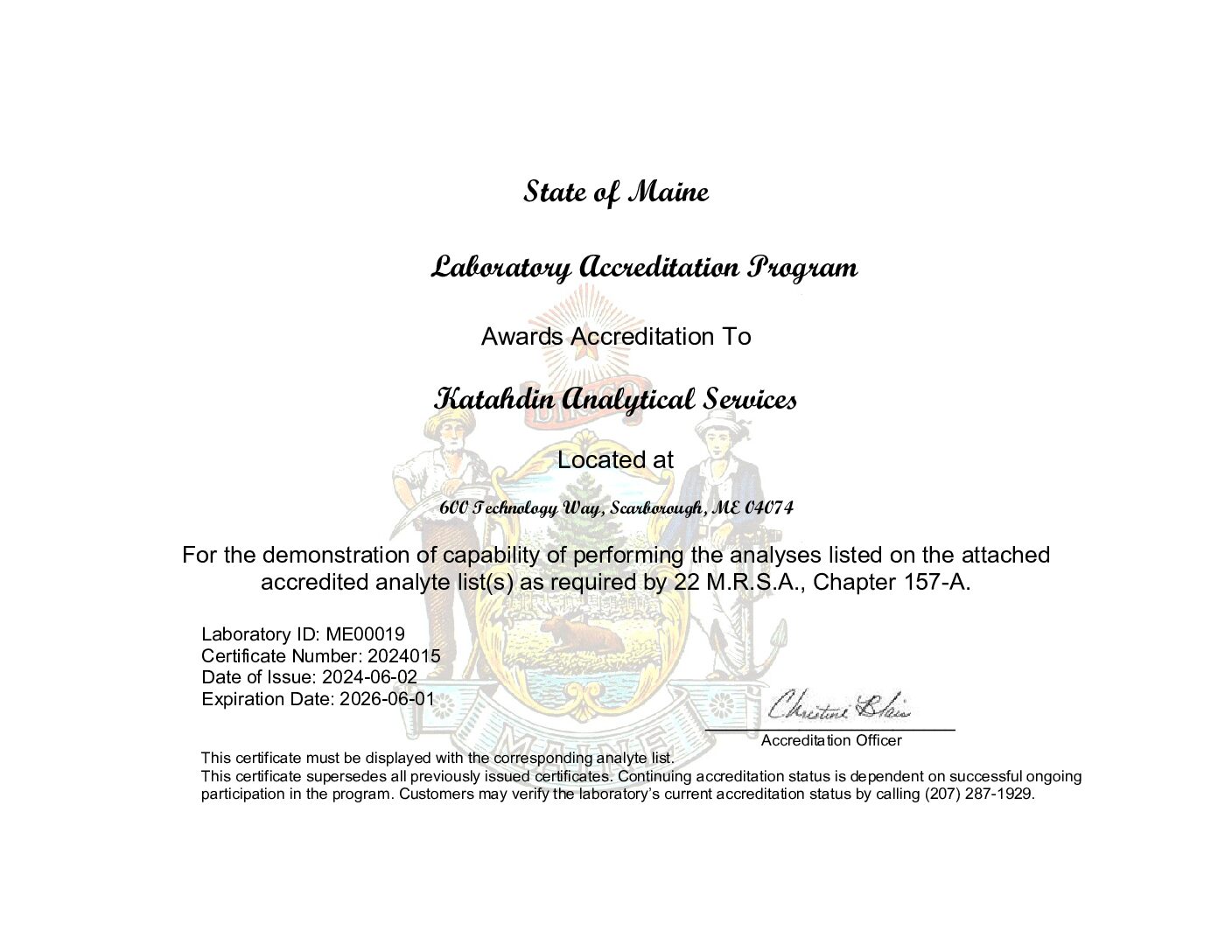

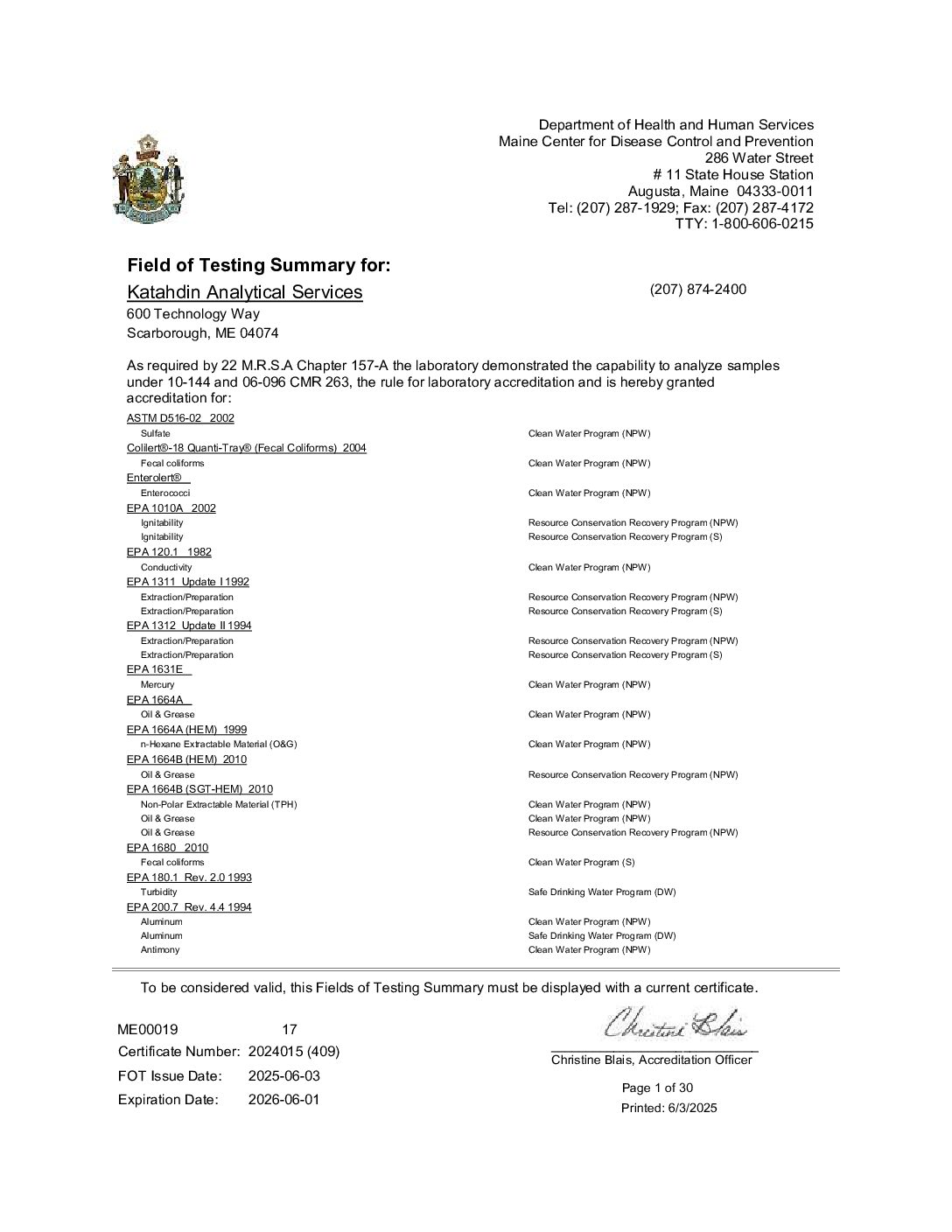

| Scarborough, ME | State of Maine, Department of Human Services | Drinking Water | Maine Laboratory Accreditation Program (ME LAP) | environmental-testing | maine | scarborough-me | drinking-water | maine-laboratory-accreditation-program-me-lap | ||

| Scarborough, ME | State of Maryland, Department of the Environment | Other | Maryland Department of the Environment Water Supply Program (MD DOE) | environmental-testing | maryland | scarborough-me | other | maryland-department-of-the-environment-water-supply-program-md-doe | ||

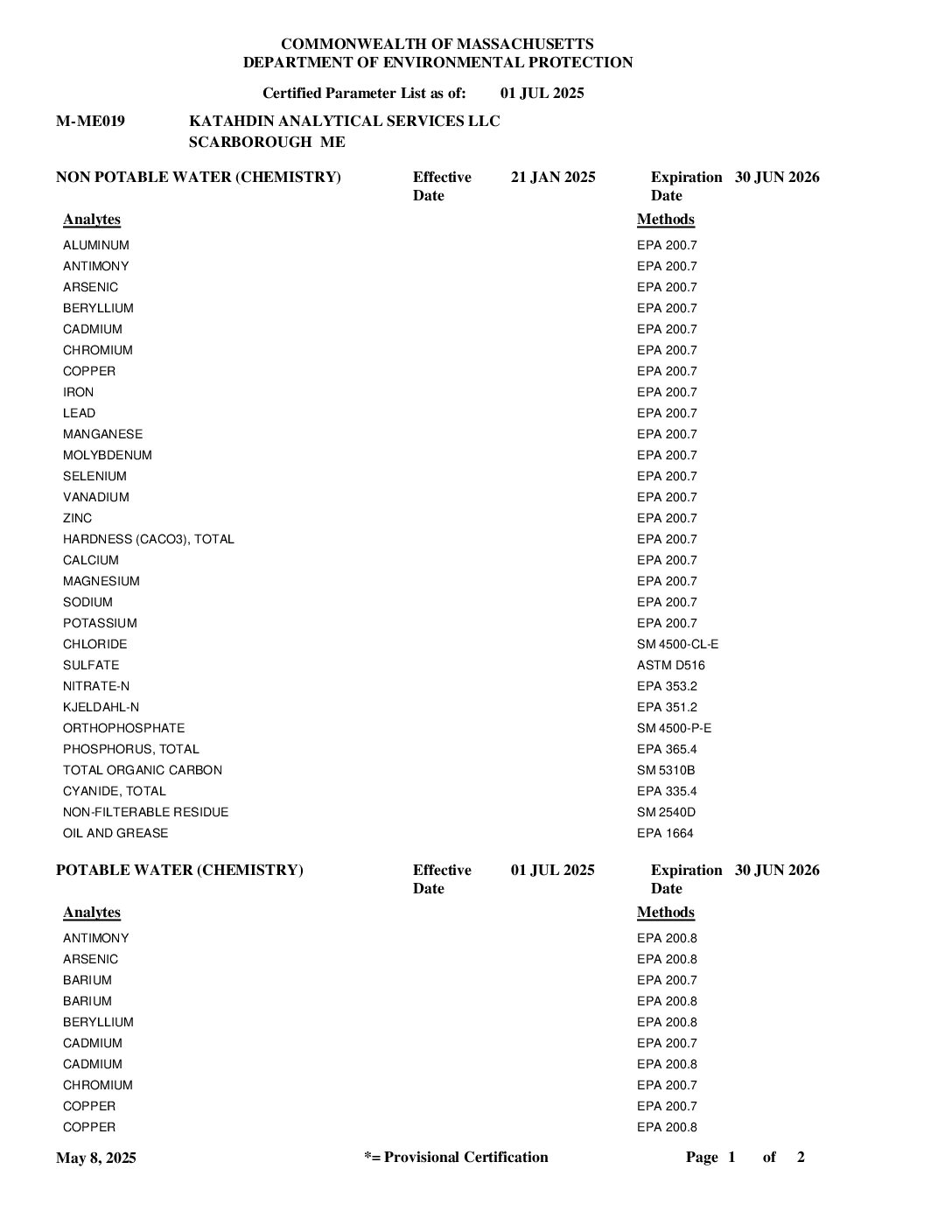

| Scarborough, ME | SGS Scarborough Commonwealth of Massachusetts, Department of Environmental Protection | Drinking Water | Massachusetts Department of Environmental Protection (MADEP) | environmental-testing | massachusetts | scarborough-me | drinking-water | massachusetts-department-of-environmental-protection-madep | ||

| Scarborough, ME | State of New Hampshire, Environmental Laboratory Accreditation Program | TNI/NELAP | New Hampshire Environmental Laboratory Accreditation Program (NH ELAP) | environmental-testing | new-hampshire | scarborough-me | tni-nelap | new-hampshire-environmental-laboratory-accreditation-program-nh-elap | ||

| Anchorage, AK | SGS Anchorage DOD | DOD, ISO/IEC 17025:2017 | American Association for Laboratory Accreditation (A2LA) | environmental-testing pfas-analysis | not-applicable | anchorage-ak | dod iso-iec-170252017 | american-association-for-laboratory-accreditation-a2la | ||

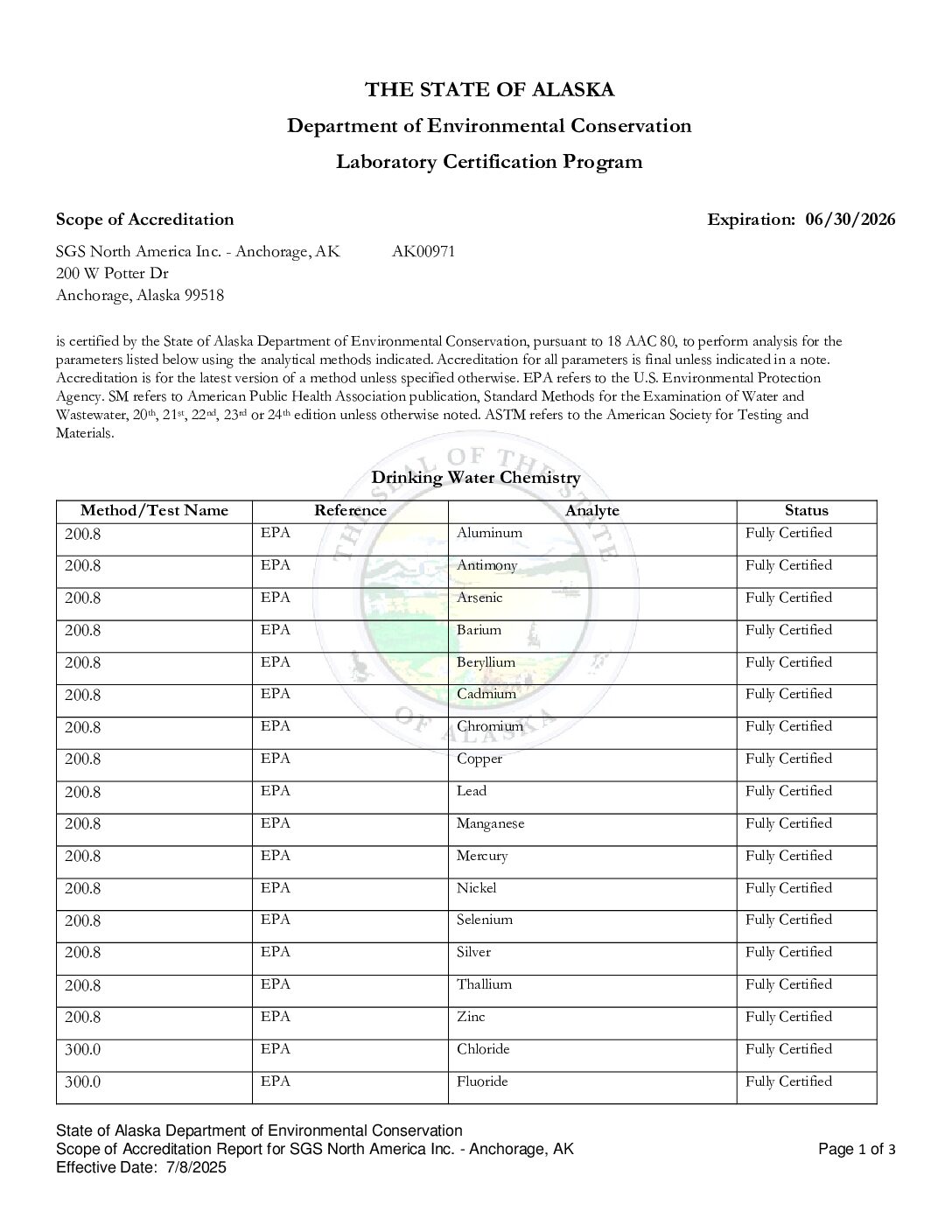

| Anchorage, AK | SGS Anchorage Alaska | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing pfas-analysis | alaska | anchorage-ak | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Anchorage, AK | SGS Anchorage DW | Drinking Water | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing pfas-analysis | alaska | anchorage-ak | drinking-water | alaska-department-of-environmental-conservation-ak-dec | ||

| Carson, CA | SGS Carson NVLAP | ISO/IEC 17025:2017, NVLAP | United States Department of Commerce National Institute of Standards & Technology | built-environment | not-applicable | carson-ca | iso-iec-170252017 nvlap | united-states-department-of-commerce-national-institute-of-standards-technology | ||

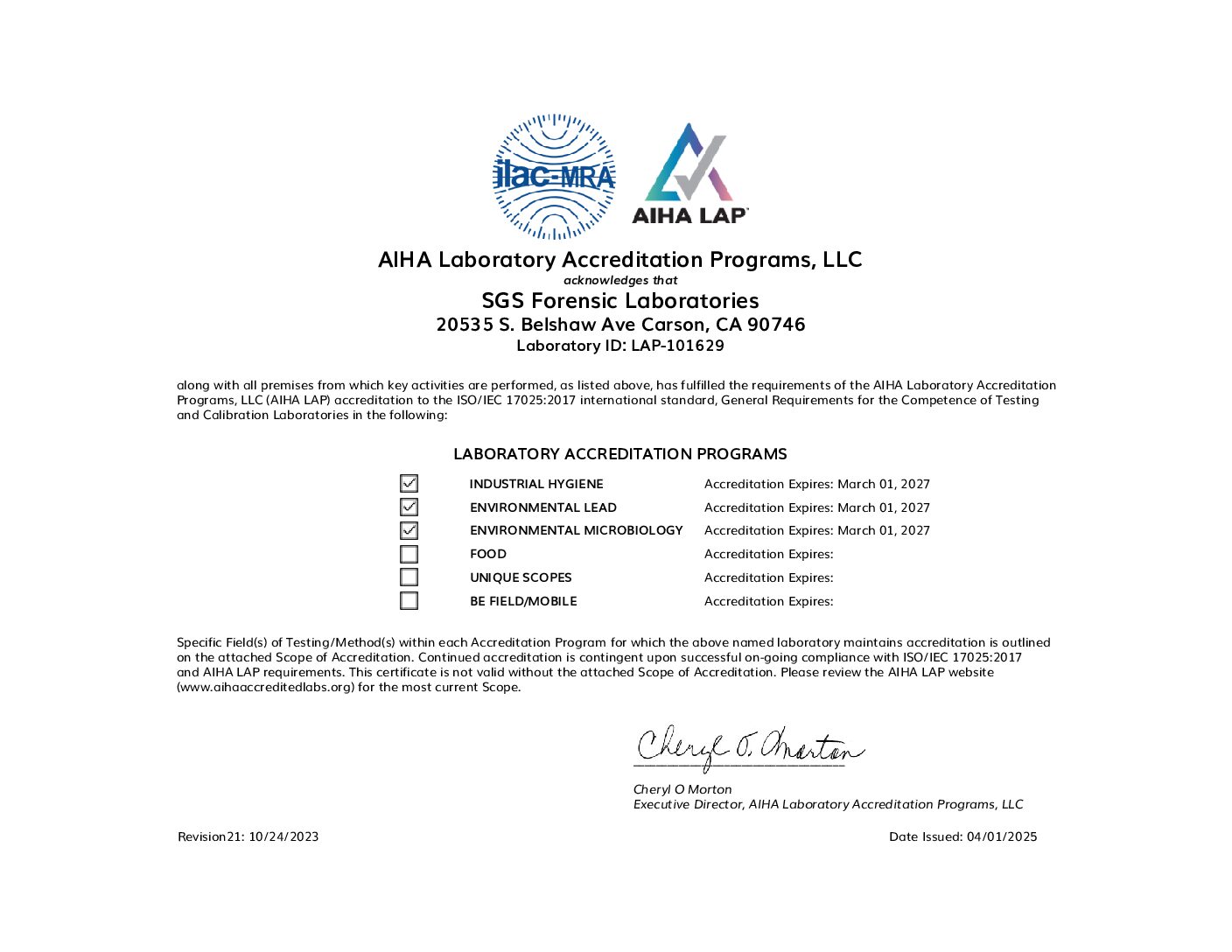

| Carson, CA | SGS Carson AIHA | AIHA, ISO/IEC 17025:2017 | AIHA Laboratory Accreditation Program (AIHA LAP) | built-environment | not-applicable | carson-ca | aiha iso-iec-170252017 | aiha-laboratory-accreditation-program-aiha-lap | ||

| Carson, CA | SGS Carson USDA | Foreign Soil | USDA | built-environment | not-applicable | carson-ca | foreign-soil | usda | ||

| Carson, CA | SGS Carson Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | built-environment | arizona | carson-ca | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

| Carson, CA | SGS Carson California | TNI - 2 (California) | California Waterboards | built-environment | california | carson-ca | tni-2-california | california-waterboards | ||

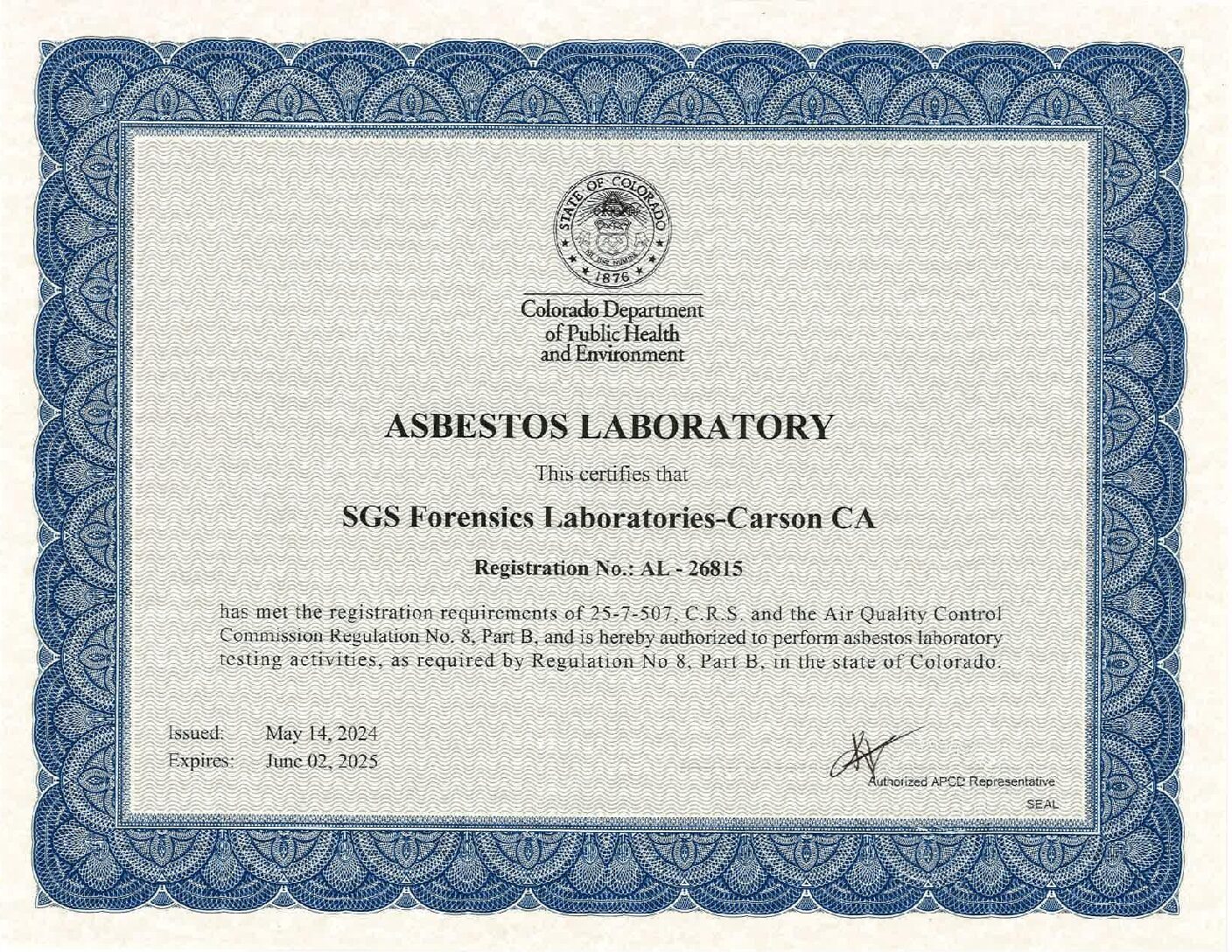

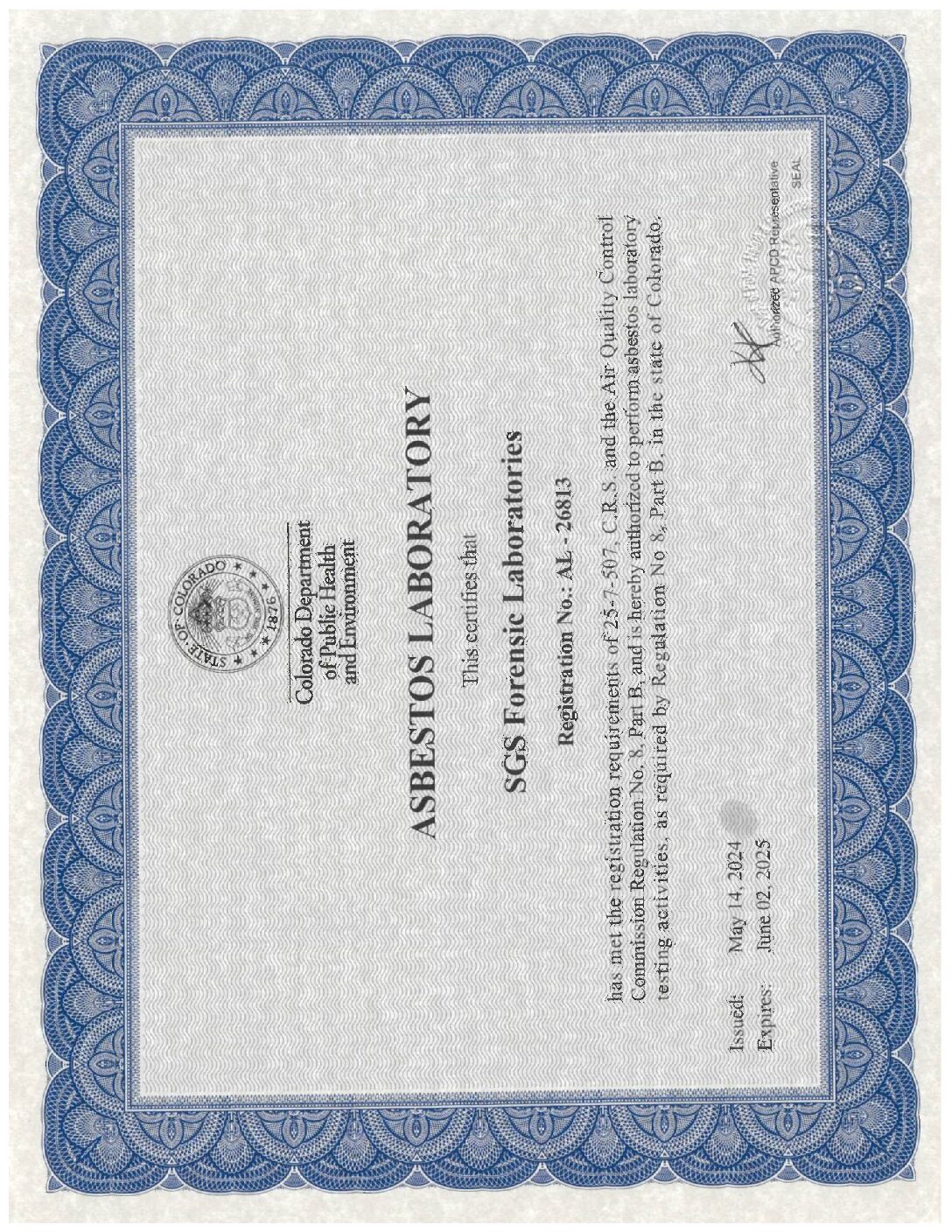

| Carson, CA | SGS Carson Colorado | Drinking Water | Colorado Department of Public Health and Environment (CODPHE) | built-environment | colorado | carson-ca | drinking-water | colorado-department-of-public-health-and-environment-codphe | ||

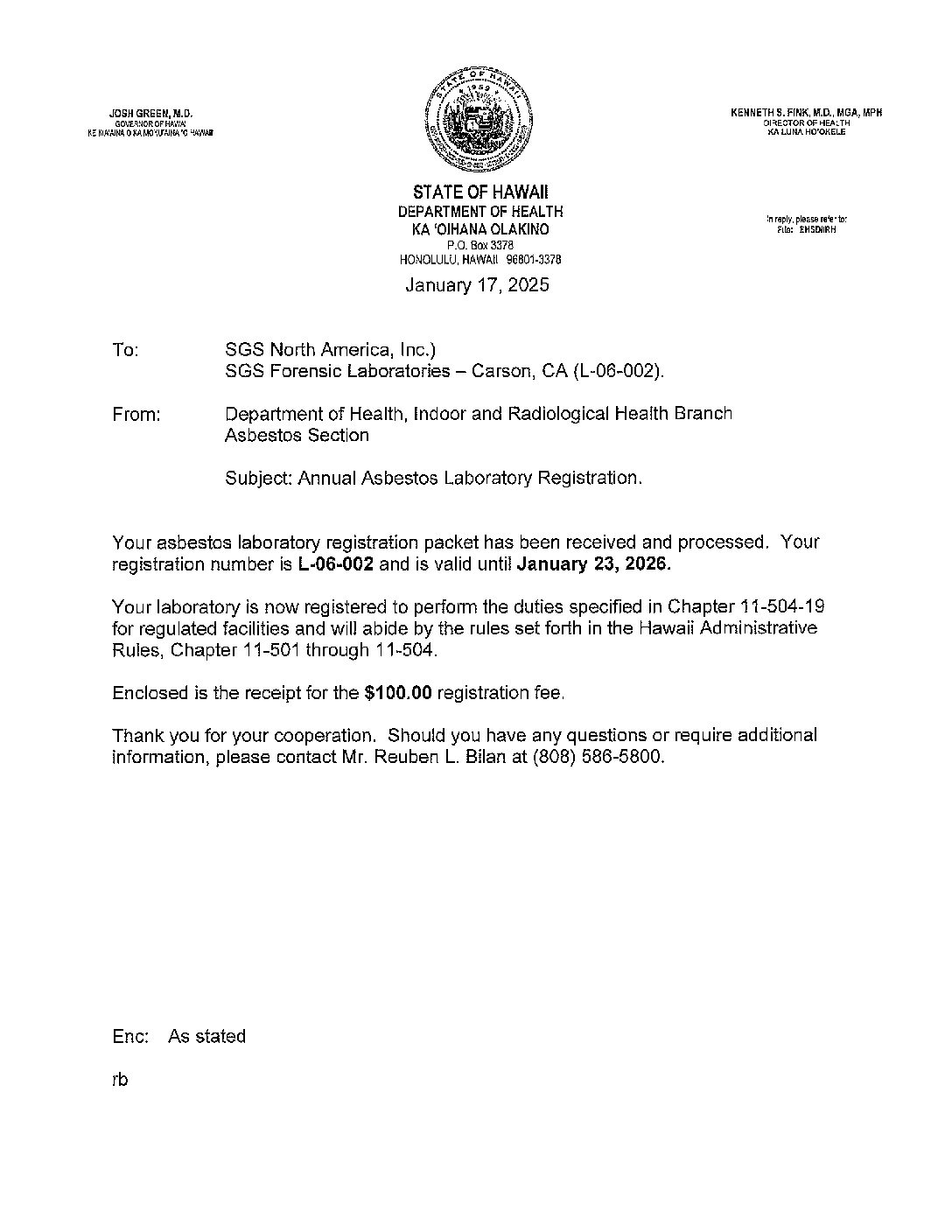

| Carson, CA | SGS Carson Hawaii | Drinking Water | State of Hawaii Department of Health (HI DOH) | built-environment | hawaii | carson-ca | drinking-water | state-of-hawaii-department-of-health-hi-doh | ||

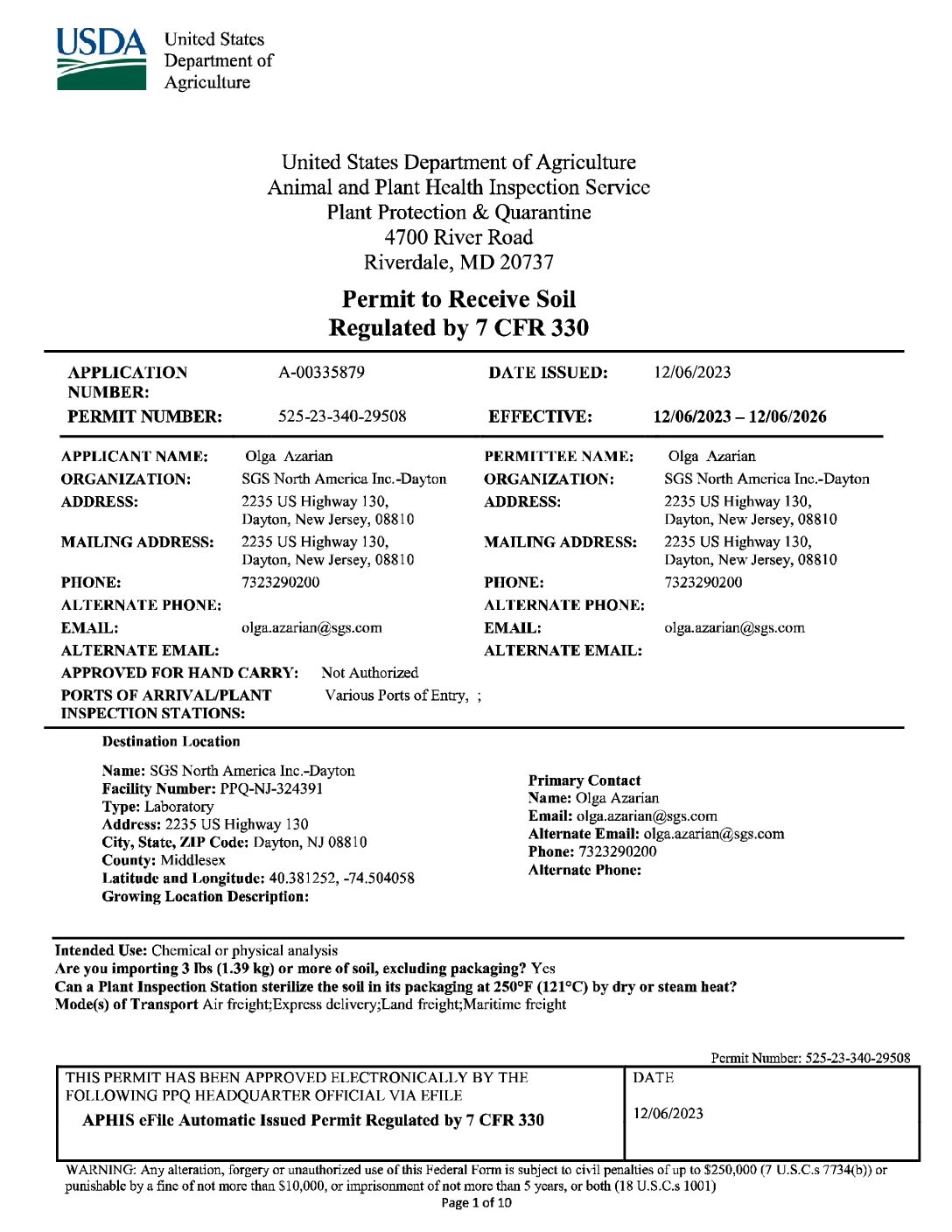

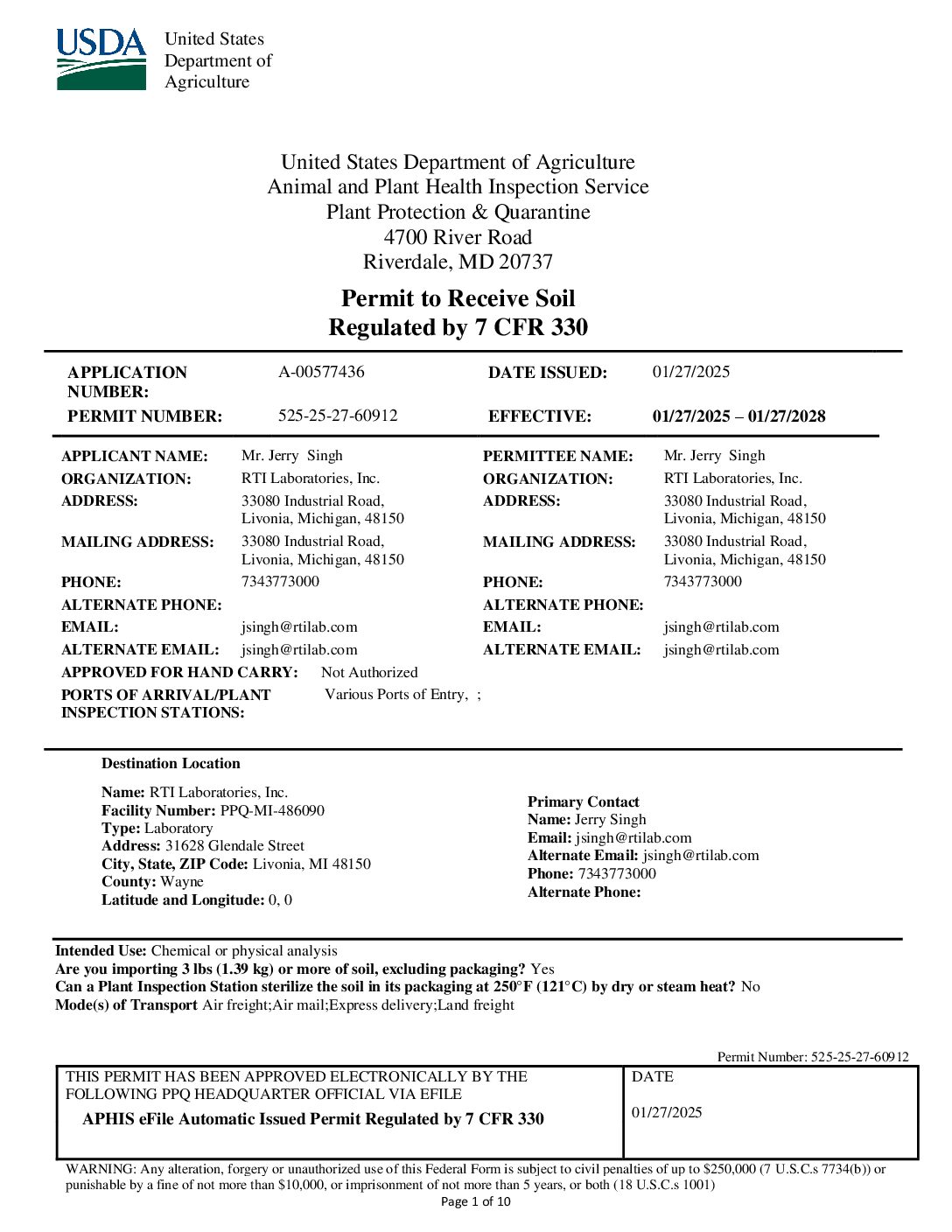

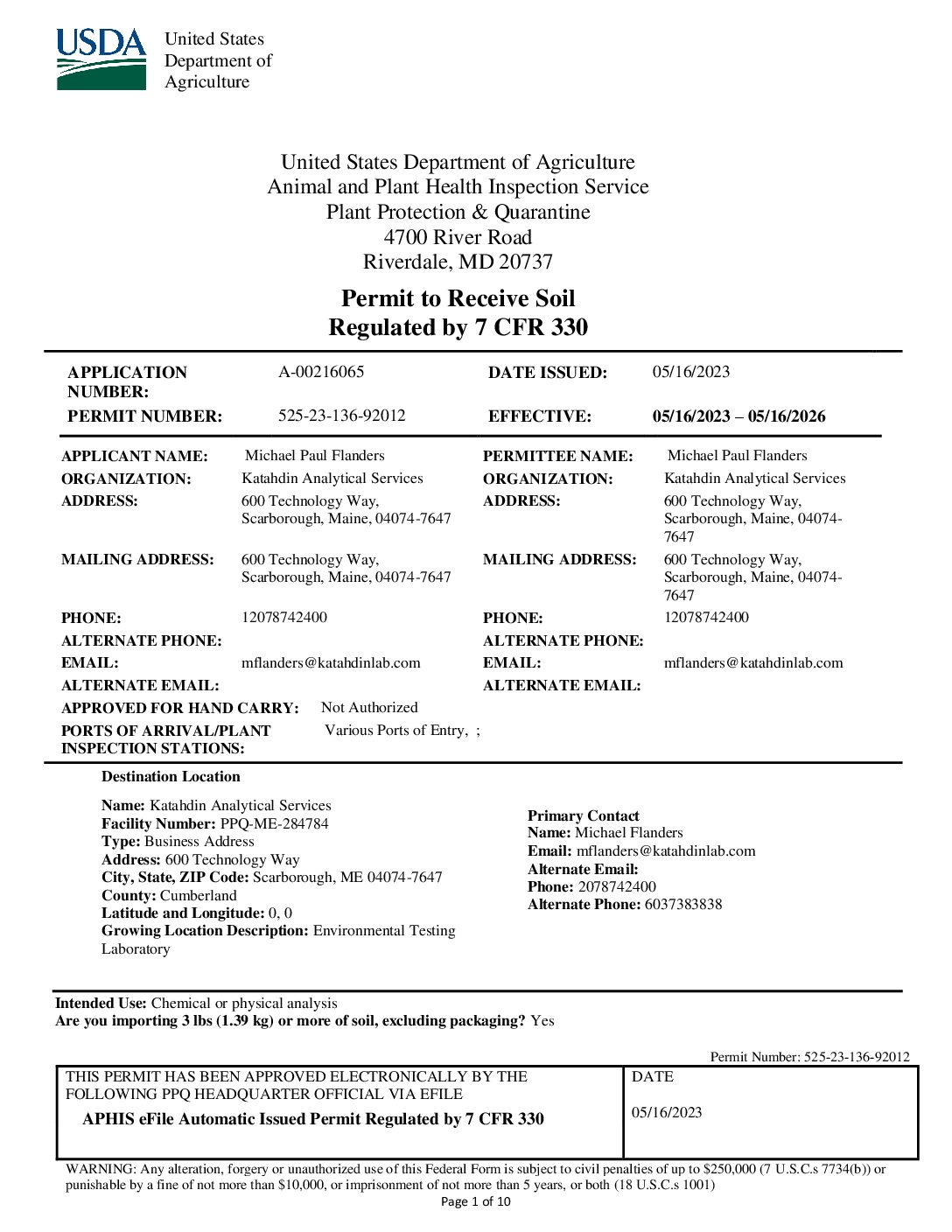

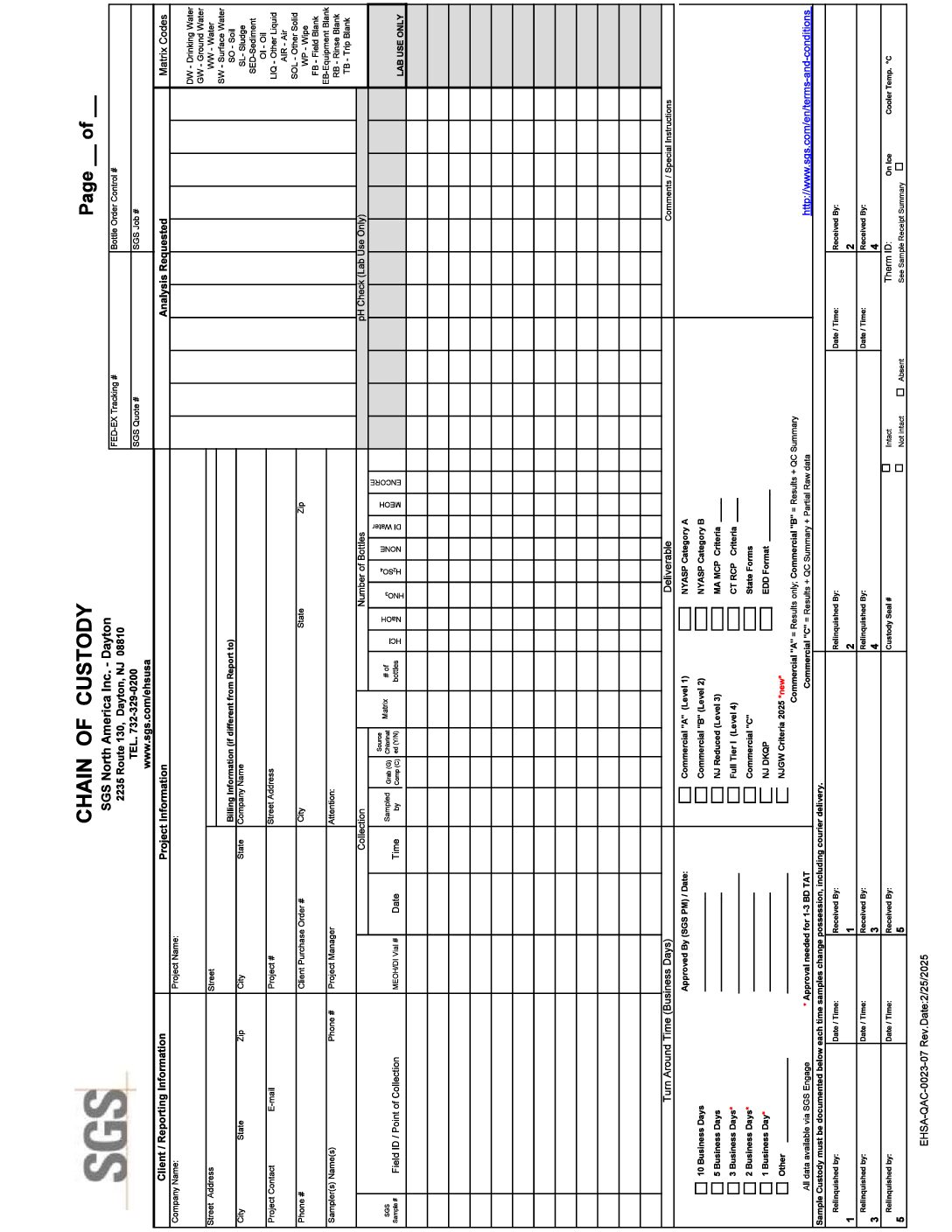

| Dayton, NJ | SGS Dayton USDA | Foreign Soil | USDA | air-quality environmental-testing pfas-analysis | not-applicable | dayton-nj | foreign-soil | usda | ||

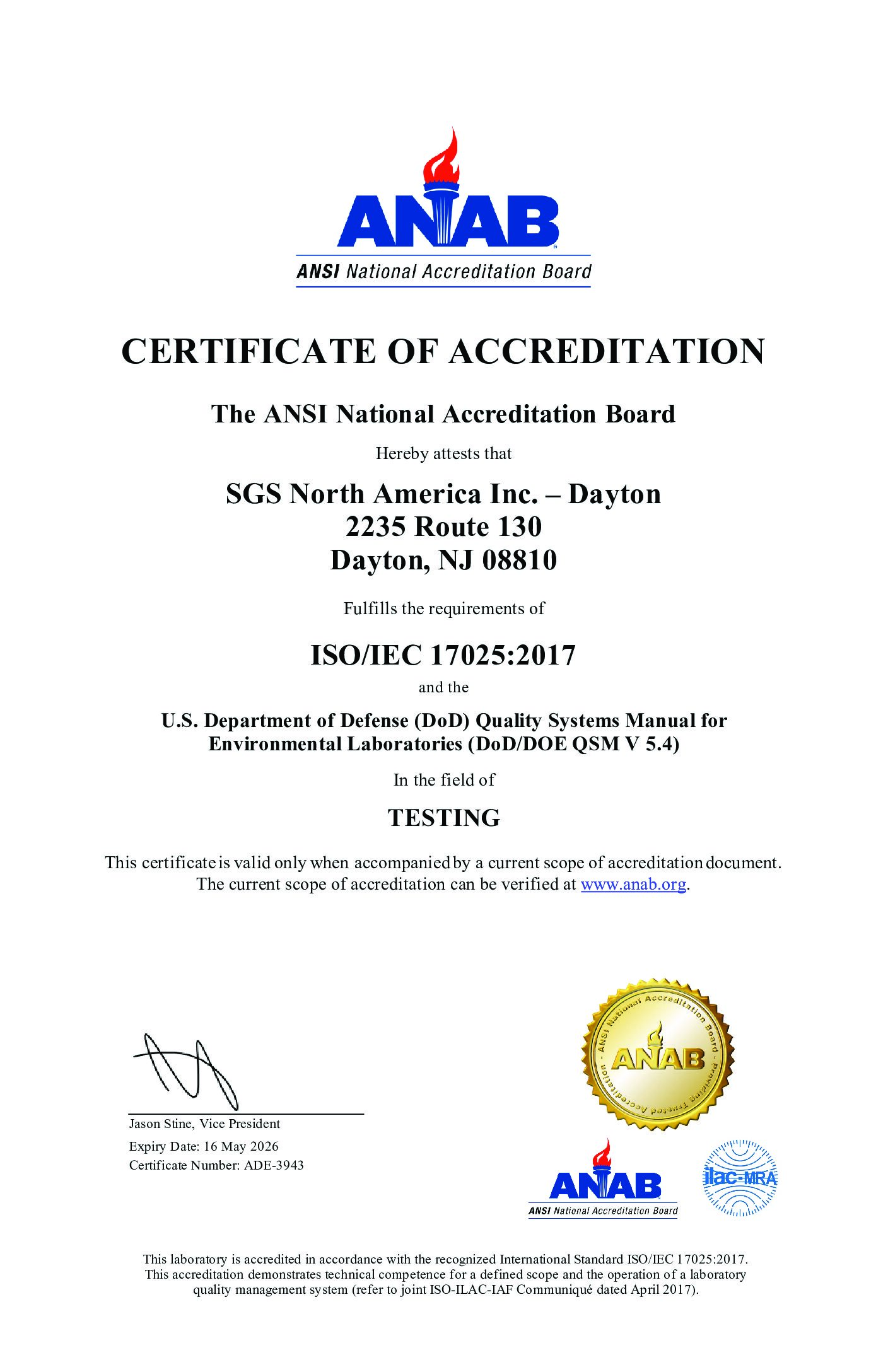

| Dayton, NJ | SGS Dayton DOD | DOD, ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | air-quality environmental-testing pfas-analysis | not-applicable | dayton-nj | dod iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

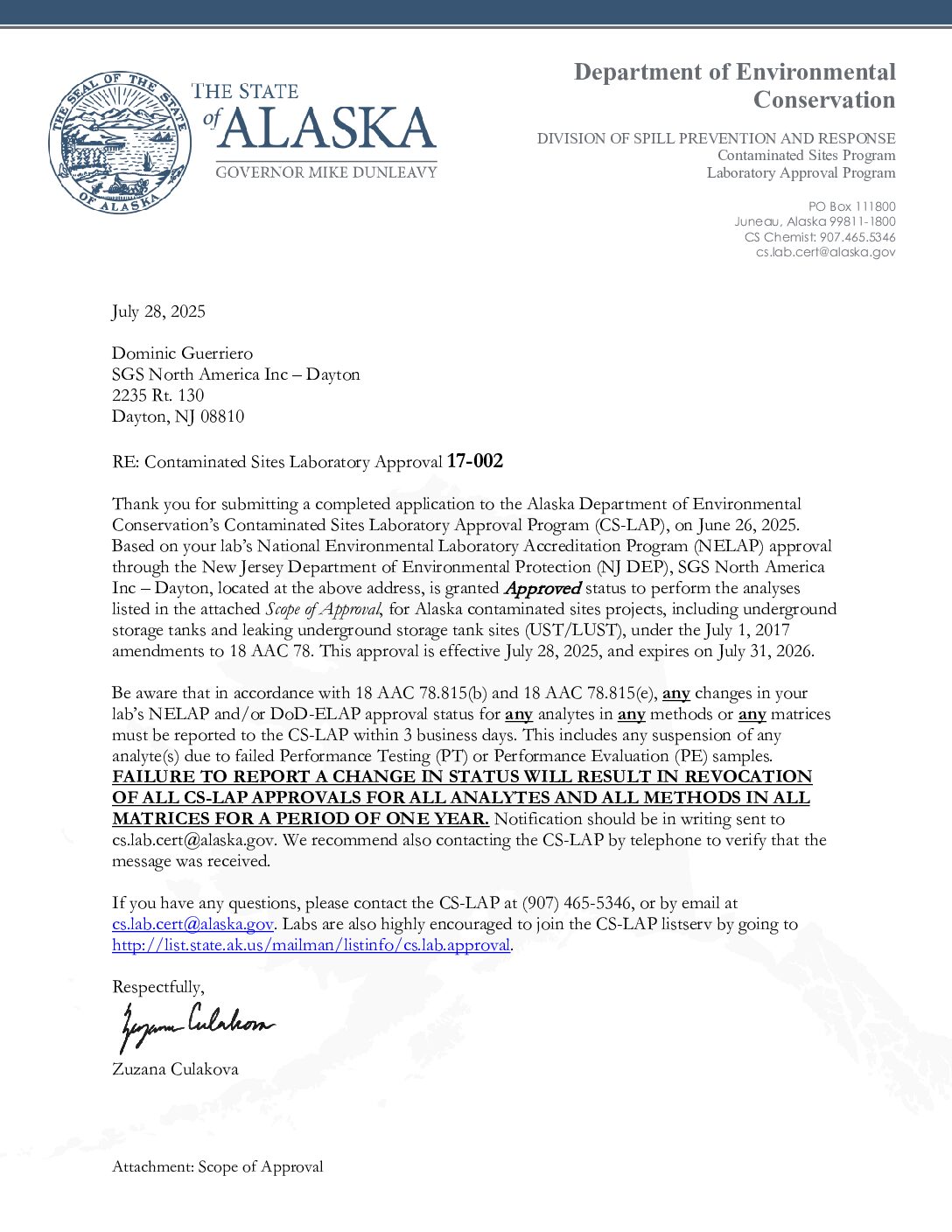

| Dayton, NJ | SGS Dayton Alaska | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | air-quality environmental-testing pfas-analysis | alaska | dayton-nj | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

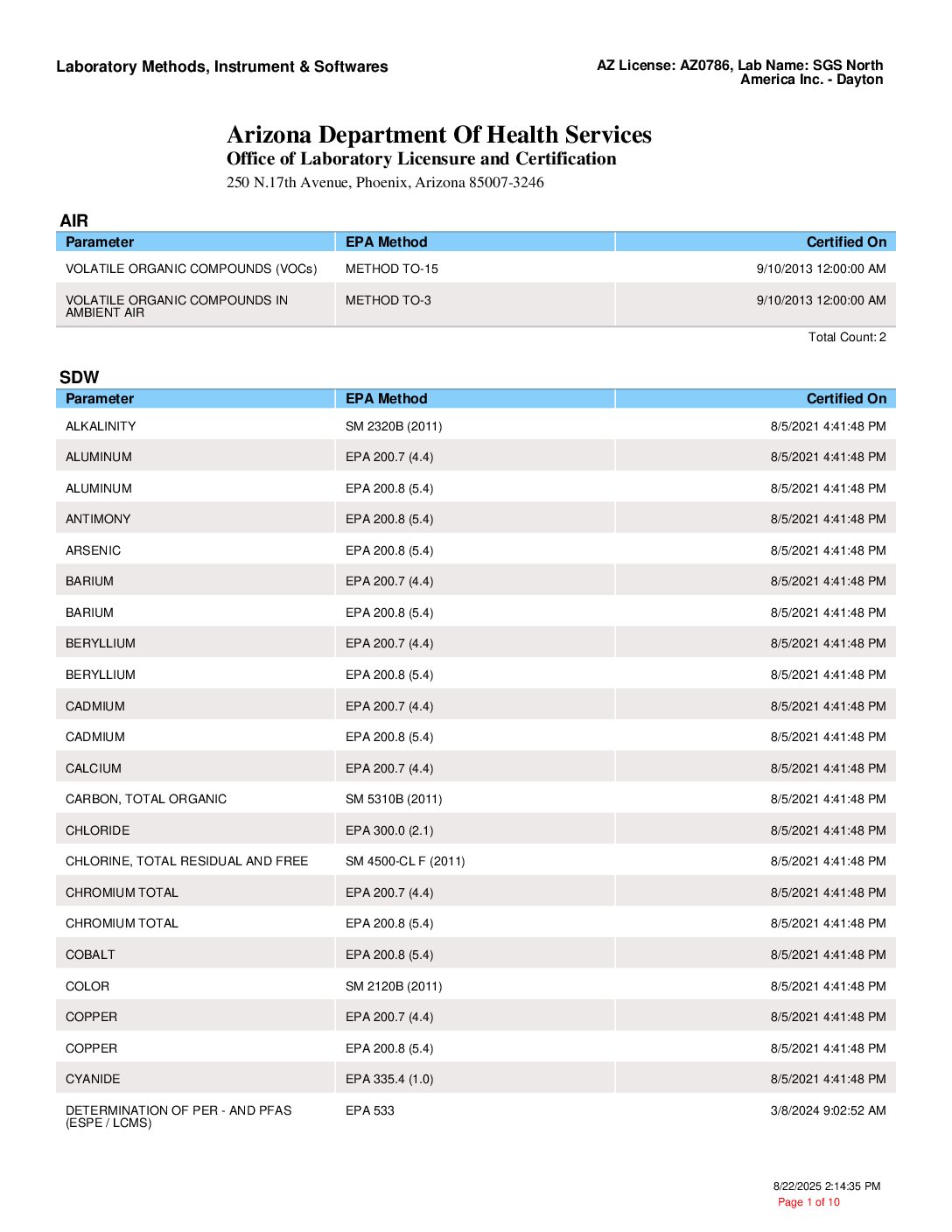

| Dayton, NJ | SGS Dayton Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | air-quality environmental-testing pfas-analysis | arizona | dayton-nj | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

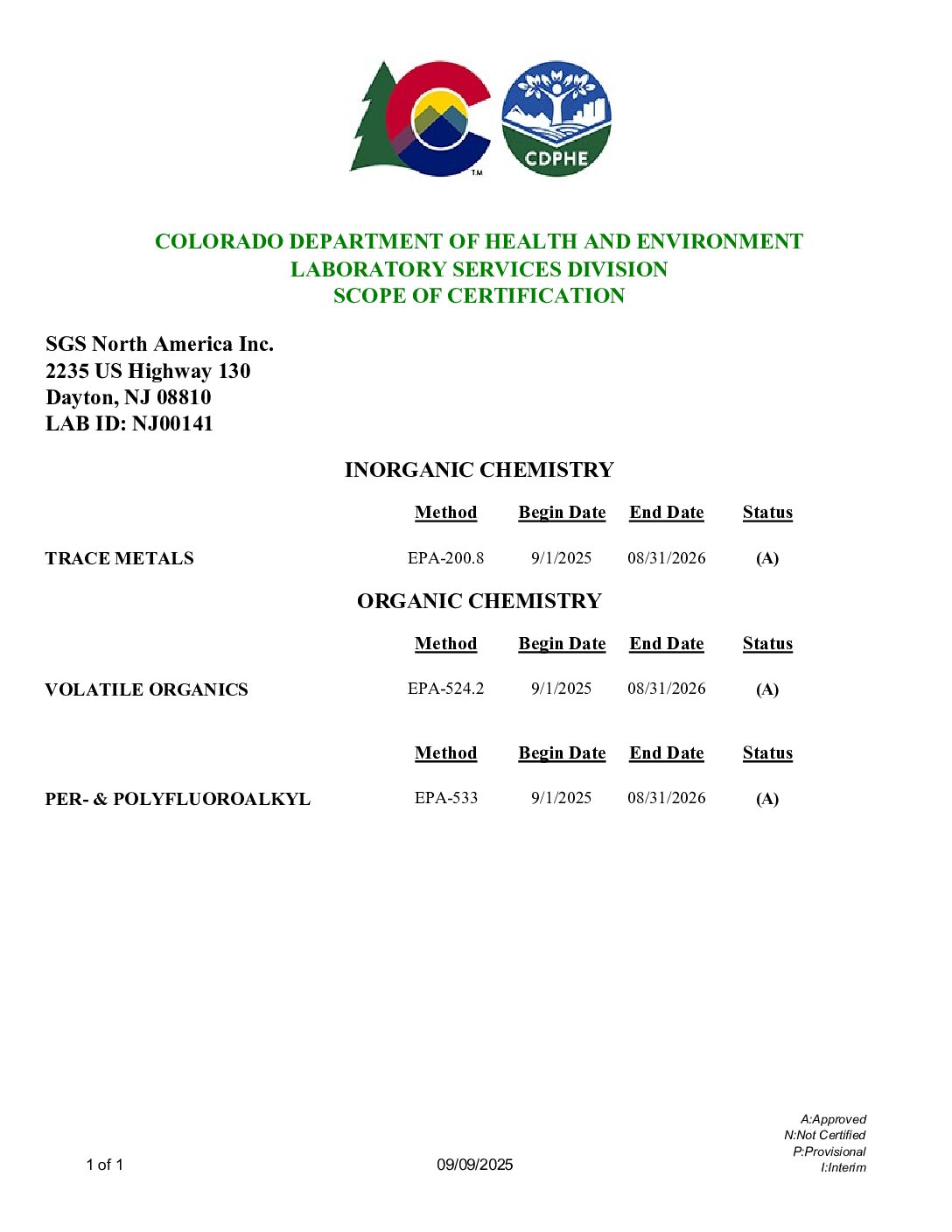

| Dayton, NJ | SGS Dayton Colorado | Drinking Water | Colorado Department of Public Health and Environment (CODPHE) | air-quality environmental-testing pfas-analysis | colorado | dayton-nj | drinking-water | colorado-department-of-public-health-and-environment-codphe | ||

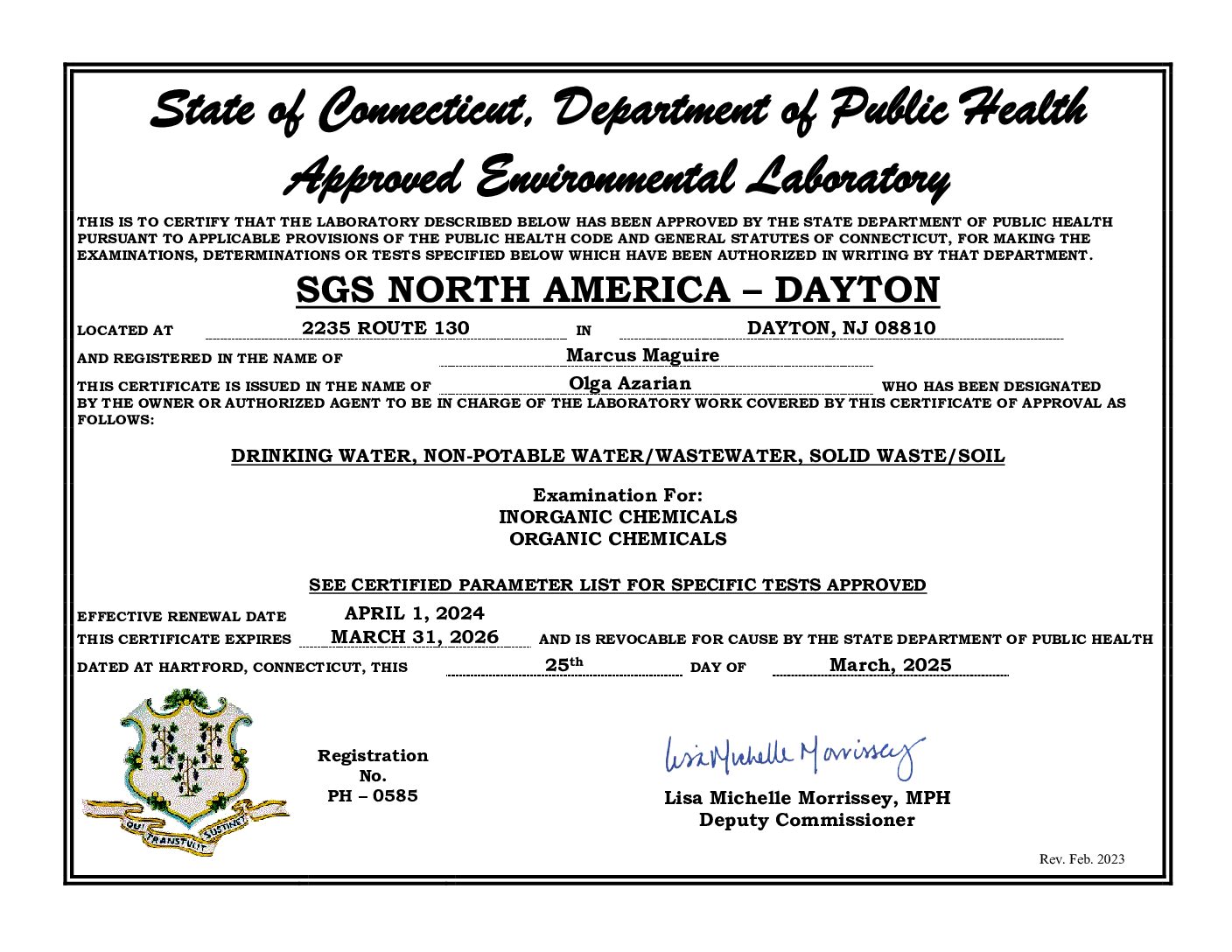

| Dayton, NJ | SGS Dayton Connecticut | Non-NELAP States | Connecticut Department of Public Health (CT DPH) | air-quality environmental-testing pfas-analysis | connecticut | dayton-nj | non-nelap-states | connecticut-department-of-public-health-ct-dph | ||

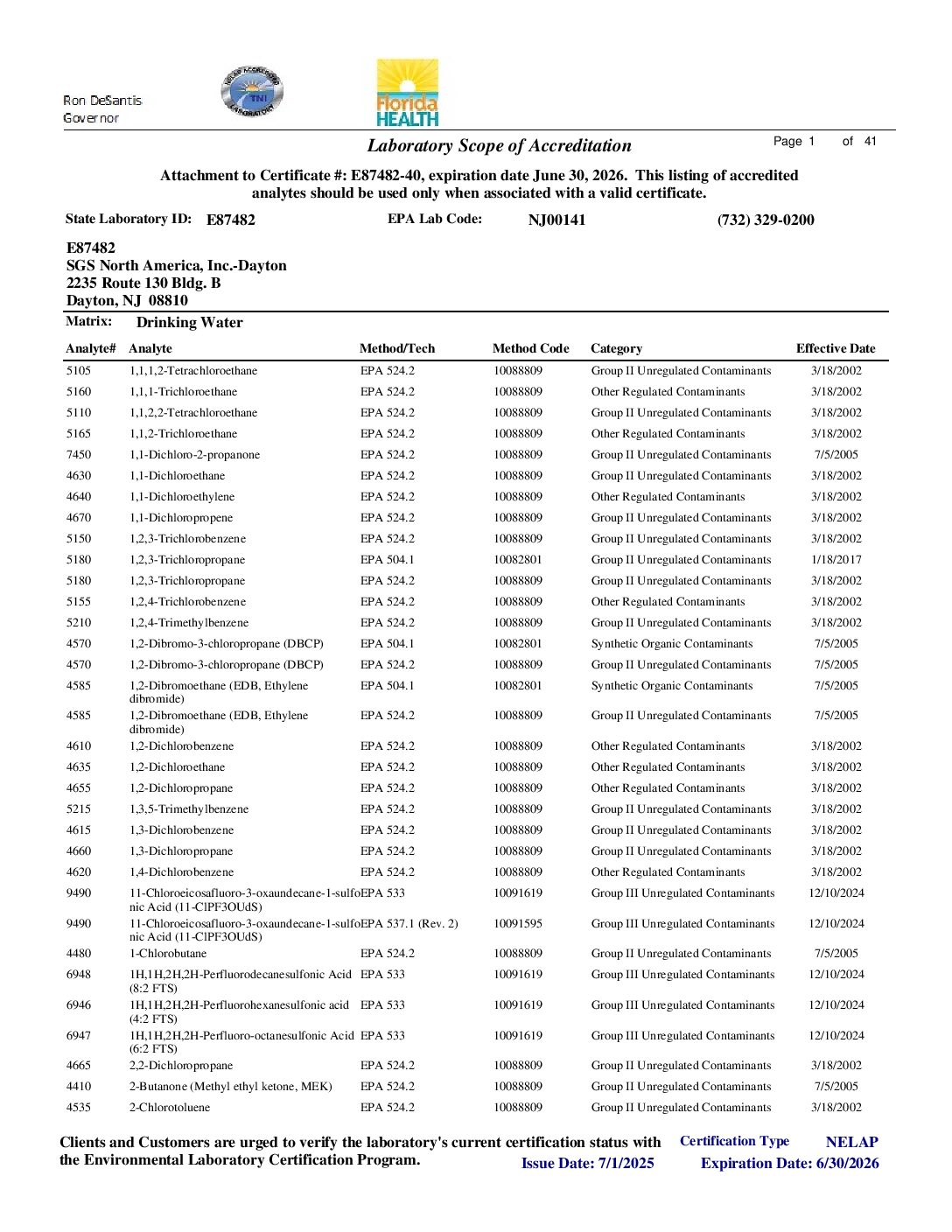

| Dayton, NJ | SGS Dayton Florida | TNI/NELAP | Florida Department of Health (FL DOH) | air-quality environmental-testing pfas-analysis | florida | dayton-nj | tni-nelap | florida-department-of-health-fl-doh | ||

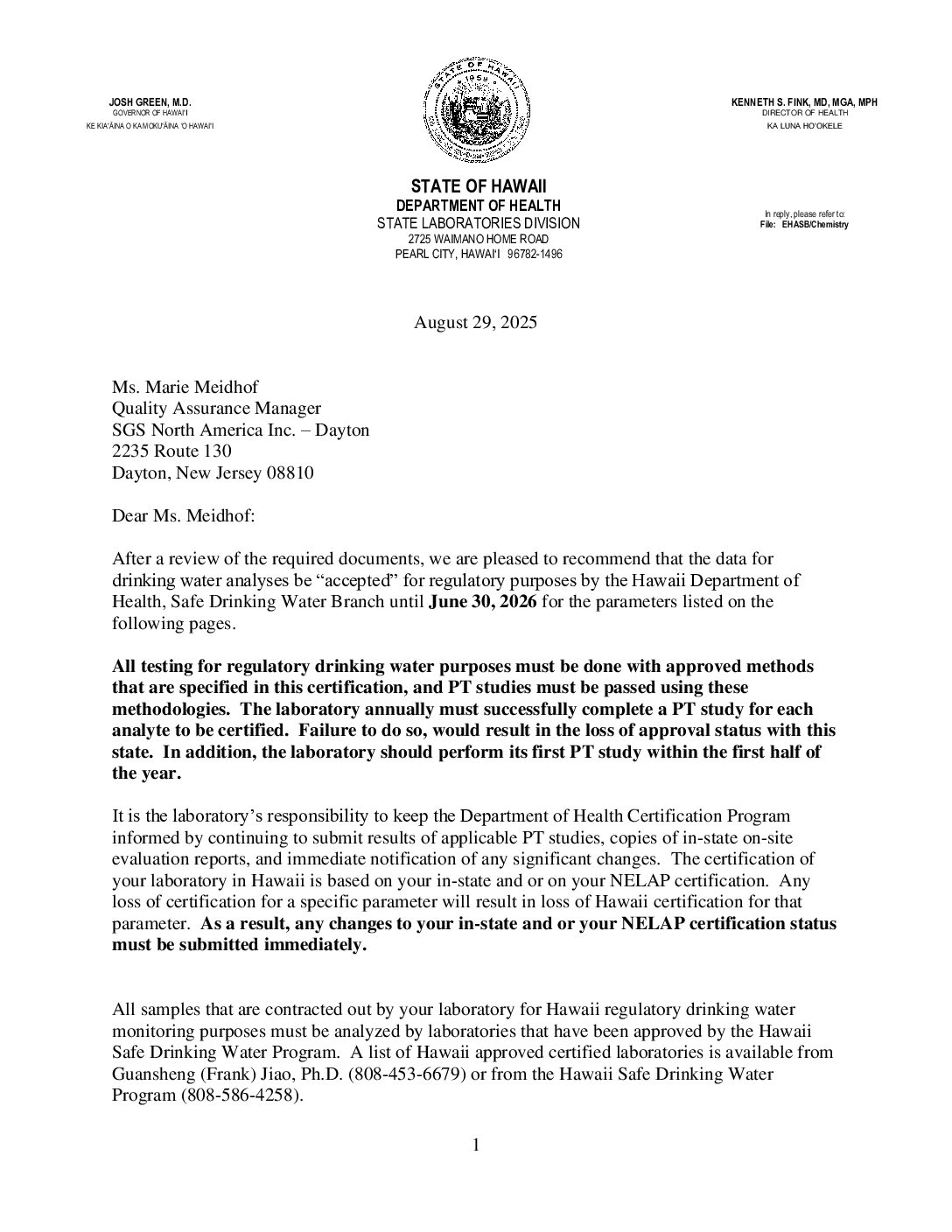

| Dayton, NJ | SGS Dayton Hawaii | Non-NELAP States | State of Hawaii Department of Health (HI DOH) | air-quality environmental-testing pfas-analysis | hawaii | dayton-nj | non-nelap-states | state-of-hawaii-department-of-health-hi-doh | ||

| Dayton, NJ | SGS Dayton Illinois | TNI/NELAP | Illinois Environmental Protection Agency (IL EPA) | air-quality environmental-testing pfas-analysis | illinois | dayton-nj | tni-nelap | illinois-environmental-protection-agency-il-epa | ||

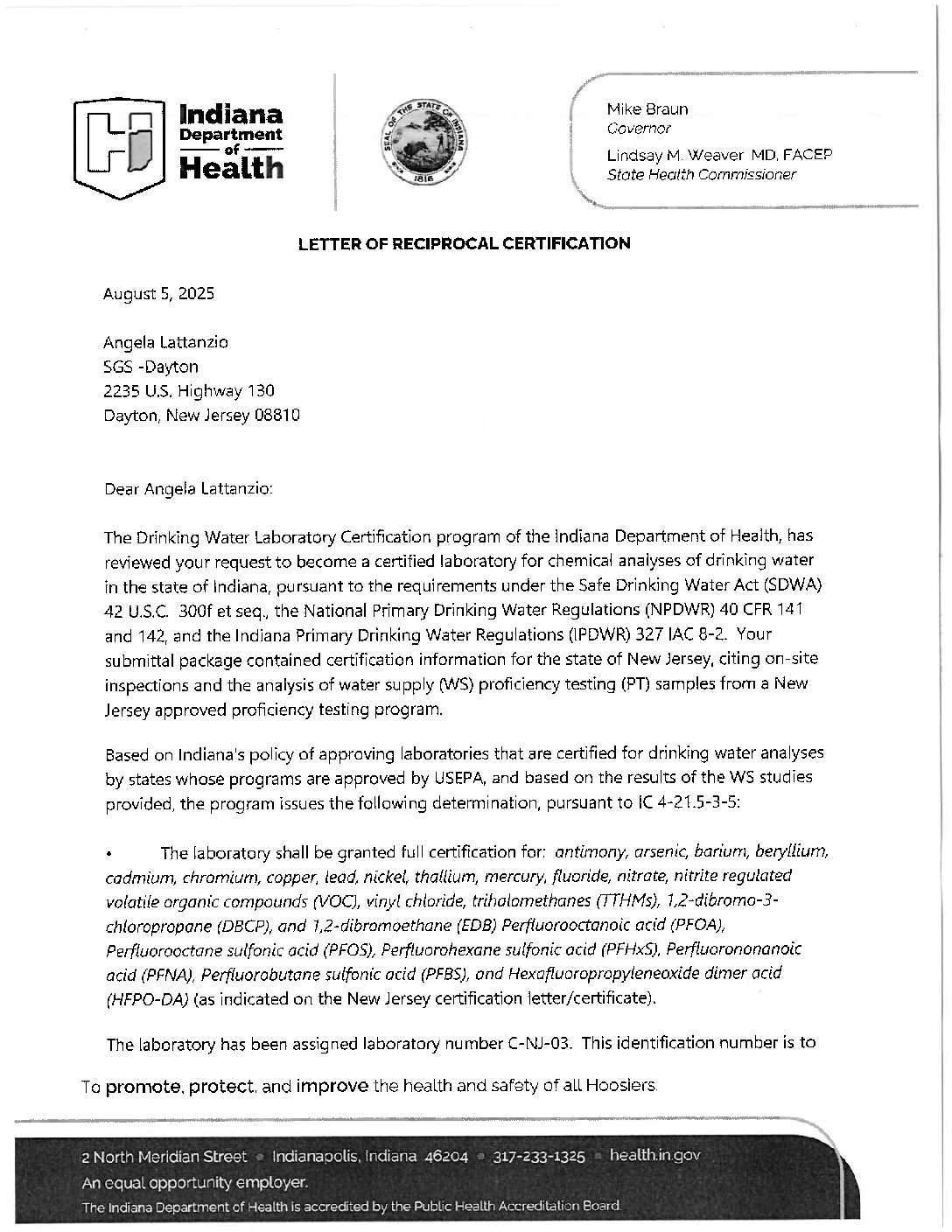

| Dayton, NJ | SGS Dayton Indiana | Drinking Water | Indiana State Department of Health (IN DOH) | air-quality environmental-testing pfas-analysis | indiana | dayton-nj | drinking-water | indiana-state-department-of-health-in-doh | ||

| Dayton, NJ | SGS Dayton Kansas | TNI/NELAP | Kansas Department of Health and Environment (KS DHE) | air-quality environmental-testing pfas-analysis | kansas | dayton-nj | tni-nelap | kansas-department-of-health-and-environment-ks-dhe | ||

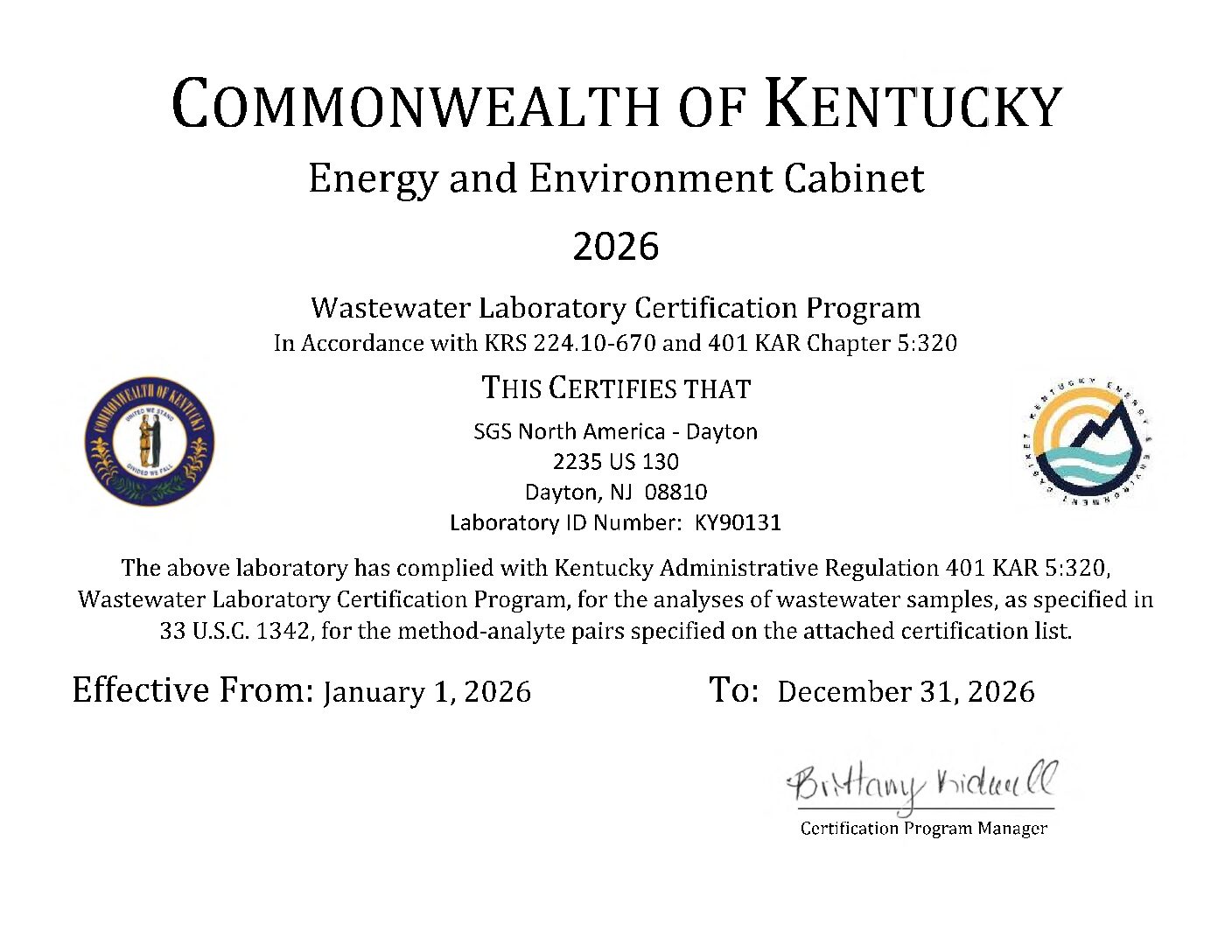

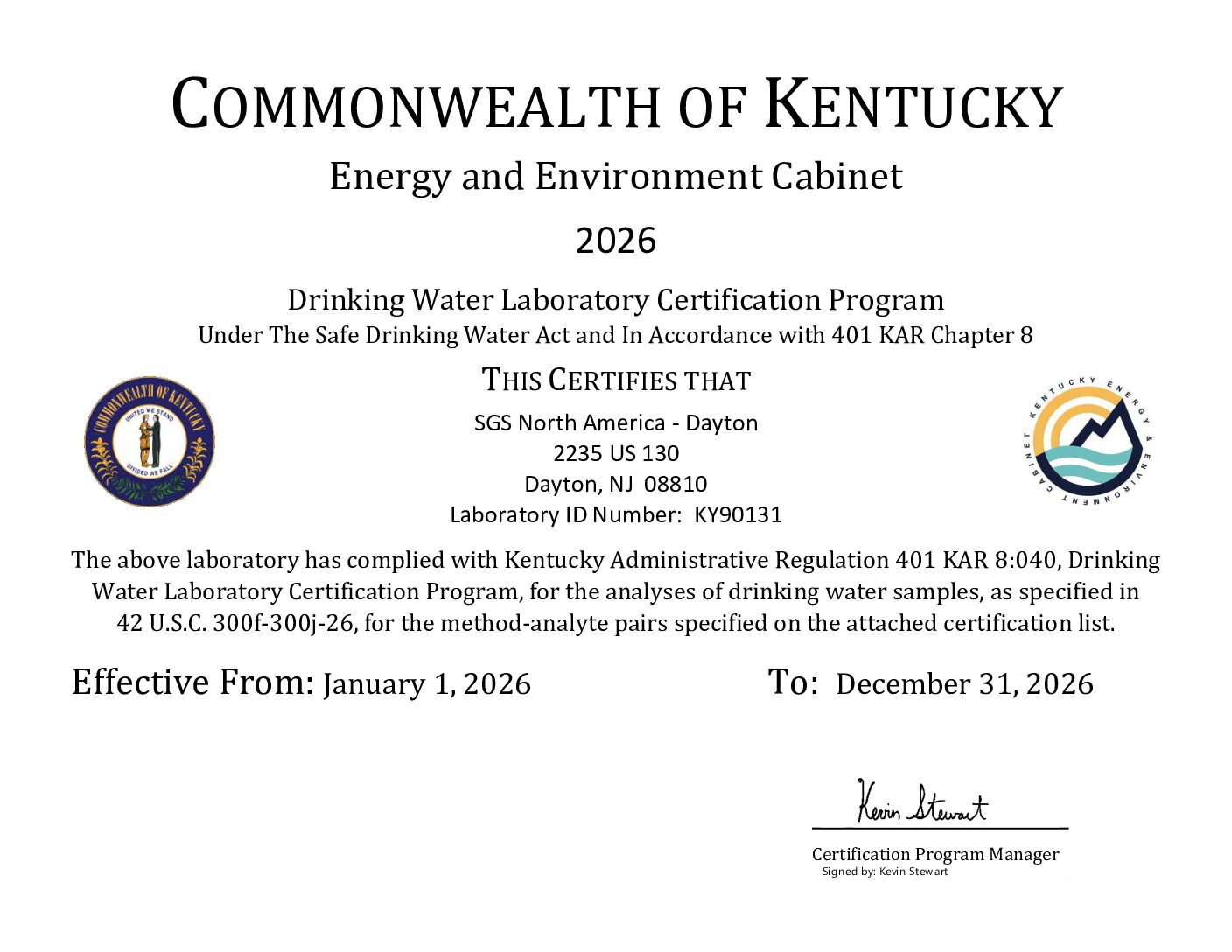

| Dayton, NJ | SGS Dayton Kentucky WW | Non-NELAP States | Kentucky Energy and Environment Cabinet (KY EEC) | air-quality environmental-testing pfas-analysis | kentucky | dayton-nj | non-nelap-states | kentucky-energy-and-environment-cabinet-ky-eec | ||

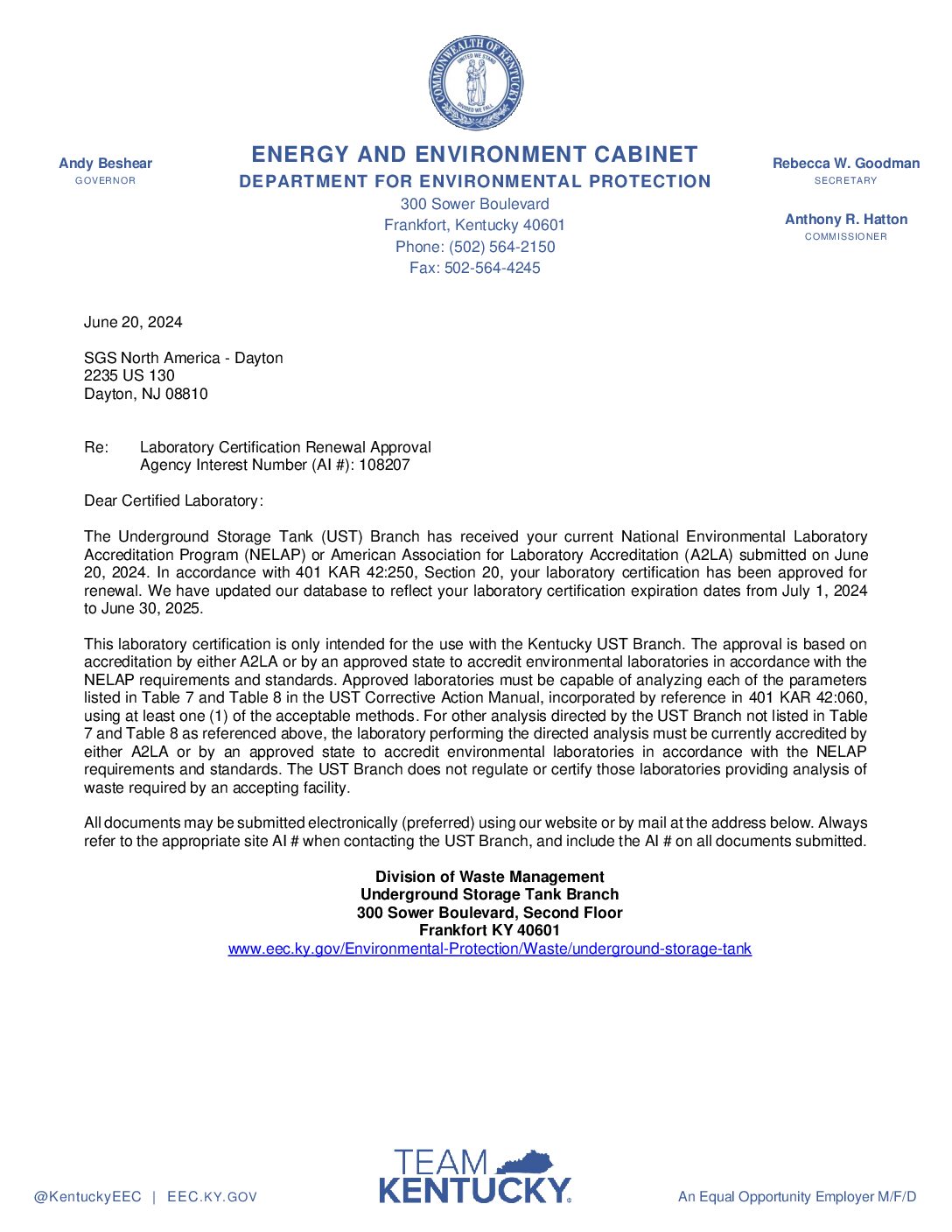

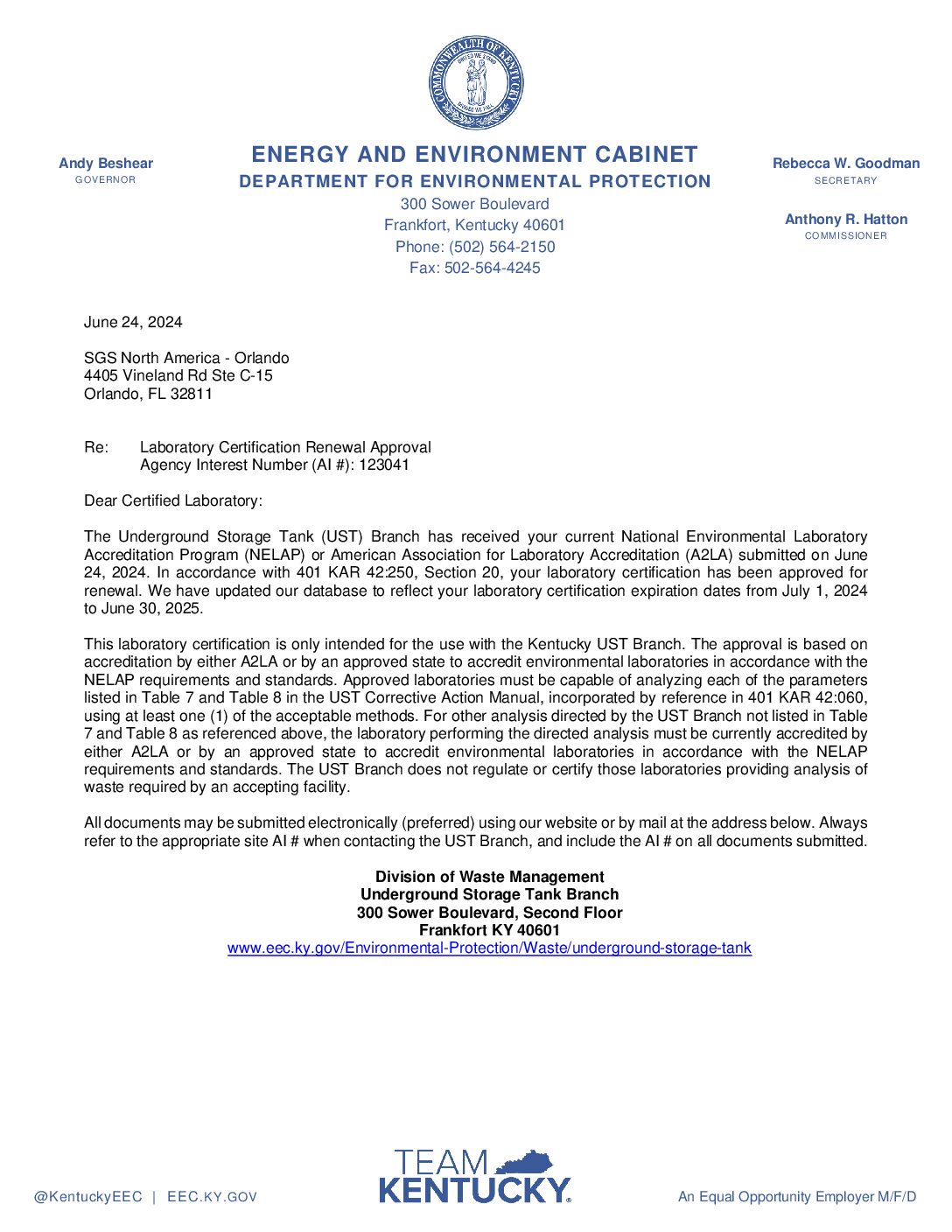

| Dayton, NJ | SGS Dayton Kentucky UST | Non-NELAP States | Kentucky Division of Waste Management Underground Storage Tank Branch (KY UST) | air-quality environmental-testing pfas-analysis | kentucky | dayton-nj | non-nelap-states | kentucky-division-of-waste-management-underground-storage-tank-branch-ky-ust | ||

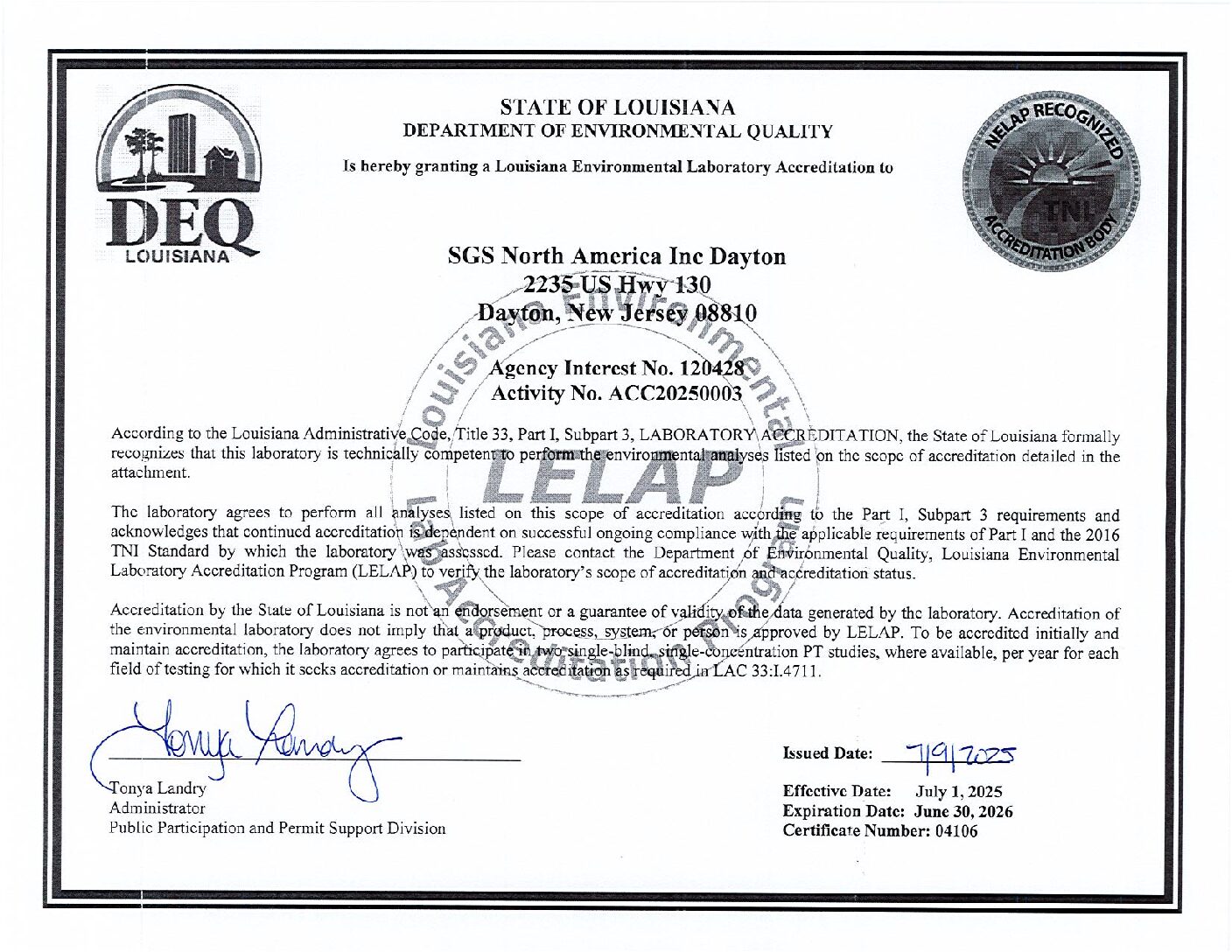

| Dayton, NJ | SGS Dayton Louisiana | TNI/NELAP | Louisiana Department of Environmental Quality (LDEQ) | air-quality environmental-testing pfas-analysis | louisiana | dayton-nj | tni-nelap | louisiana-department-of-environmental-quality-ldeq | ||

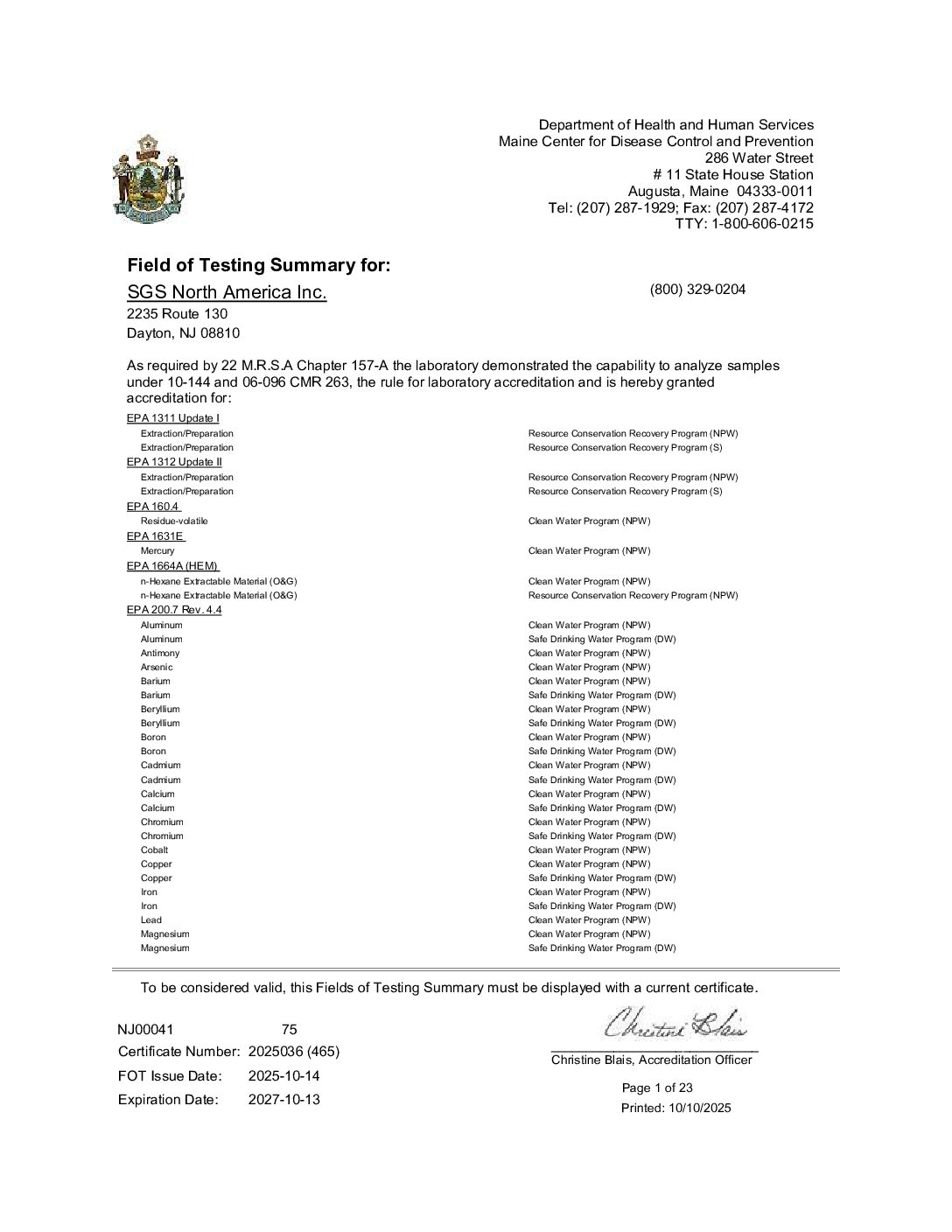

| Dayton, NJ | SGS Dayton Maine | Non-NELAP States | Maine Laboratory Accreditation Program (ME LAP) | air-quality environmental-testing pfas-analysis | maine | dayton-nj | non-nelap-states | maine-laboratory-accreditation-program-me-lap | ||

| Dayton, NJ | SGS Dayton Maryland | Non-NELAP States | Maryland Department of the Environment Water Supply Program (MD DOE) | air-quality environmental-testing pfas-analysis | maryland | dayton-nj | non-nelap-states | maryland-department-of-the-environment-water-supply-program-md-doe | ||

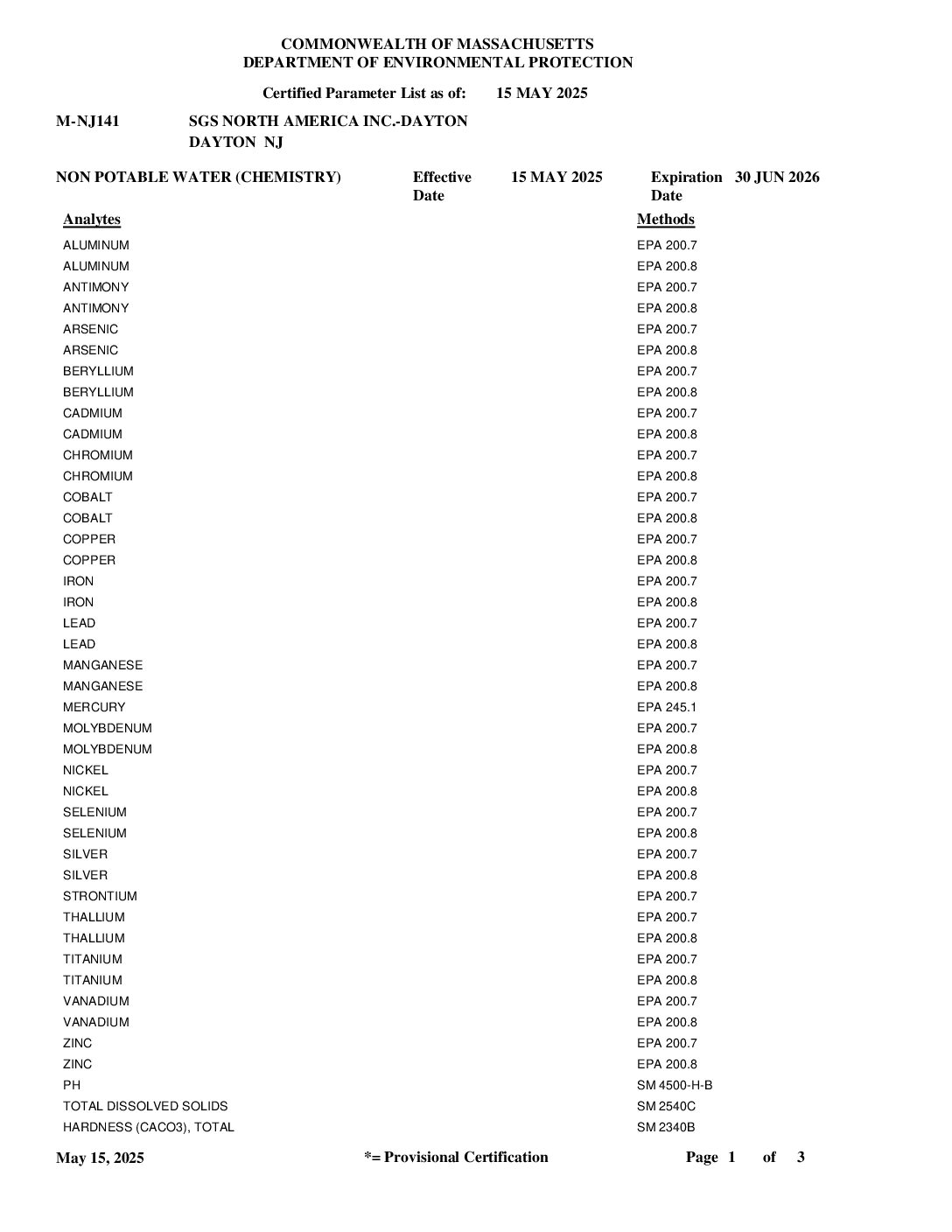

| Dayton, NJ | SGS Dayton Massachusetts | Non-NELAP States | Massachusetts Department of Environmental Protection (MADEP) | air-quality environmental-testing pfas-analysis | massachusetts | dayton-nj | non-nelap-states | massachusetts-department-of-environmental-protection-madep | ||

| Dayton, NJ | SGS Dayton Minnesota | TNI/NELAP | Minnesota Environmental Laboratory Accreditation Program (MN ELAP) | air-quality environmental-testing pfas-analysis | minnesota | dayton-nj | tni-nelap | minnesota-environmental-laboratory-accreditation-program-mn-elap | ||

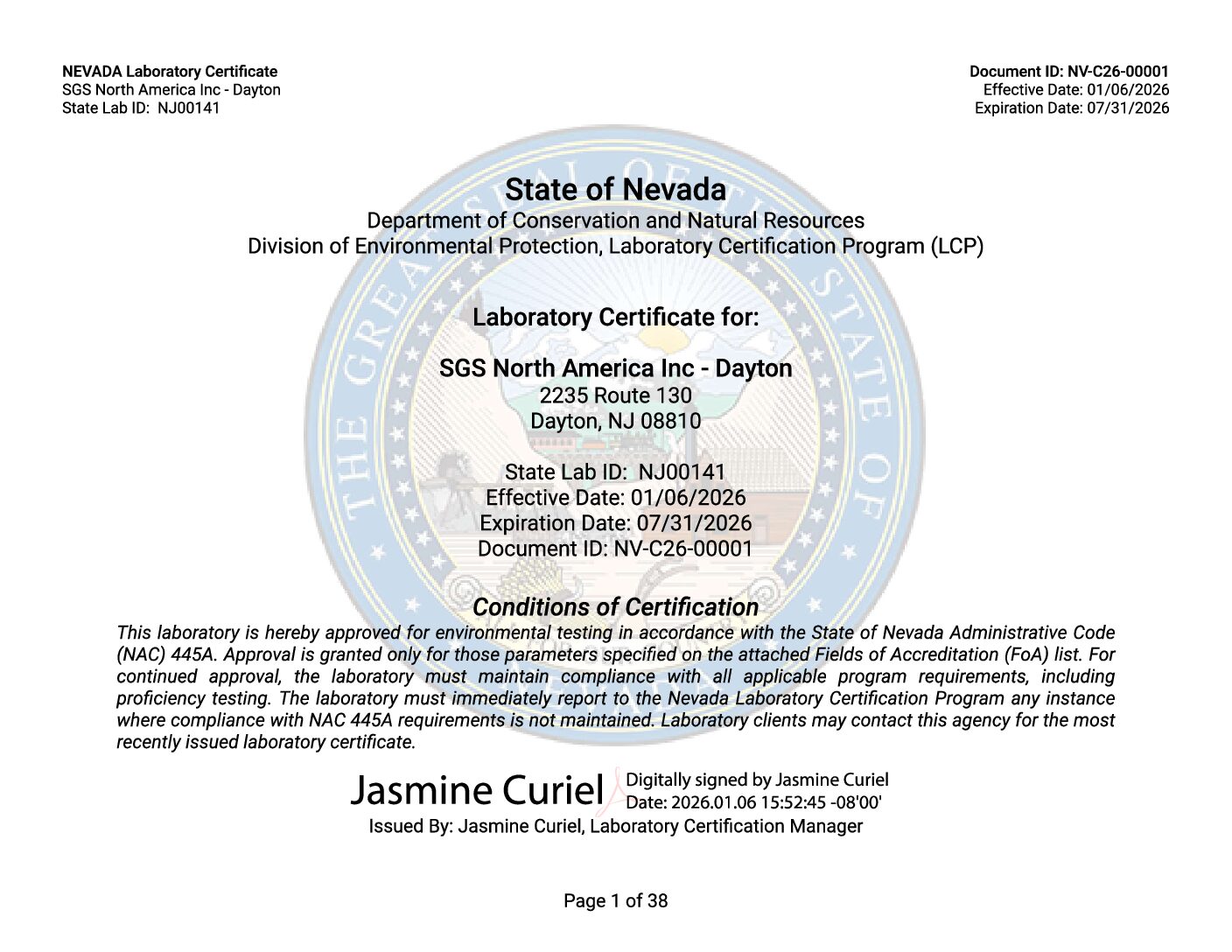

| Dayton, NJ | SGS Dayton Nevada | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | air-quality environmental-testing pfas-analysis | nevada | dayton-nj | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Dayton, NJ | SGS Dayton New Hampshire | TNI/NELAP | New Hampshire Environmental Laboratory Accreditation Program (NH ELAP) | air-quality environmental-testing pfas-analysis | new-hampshire | dayton-nj | tni-nelap | new-hampshire-environmental-laboratory-accreditation-program-nh-elap | ||

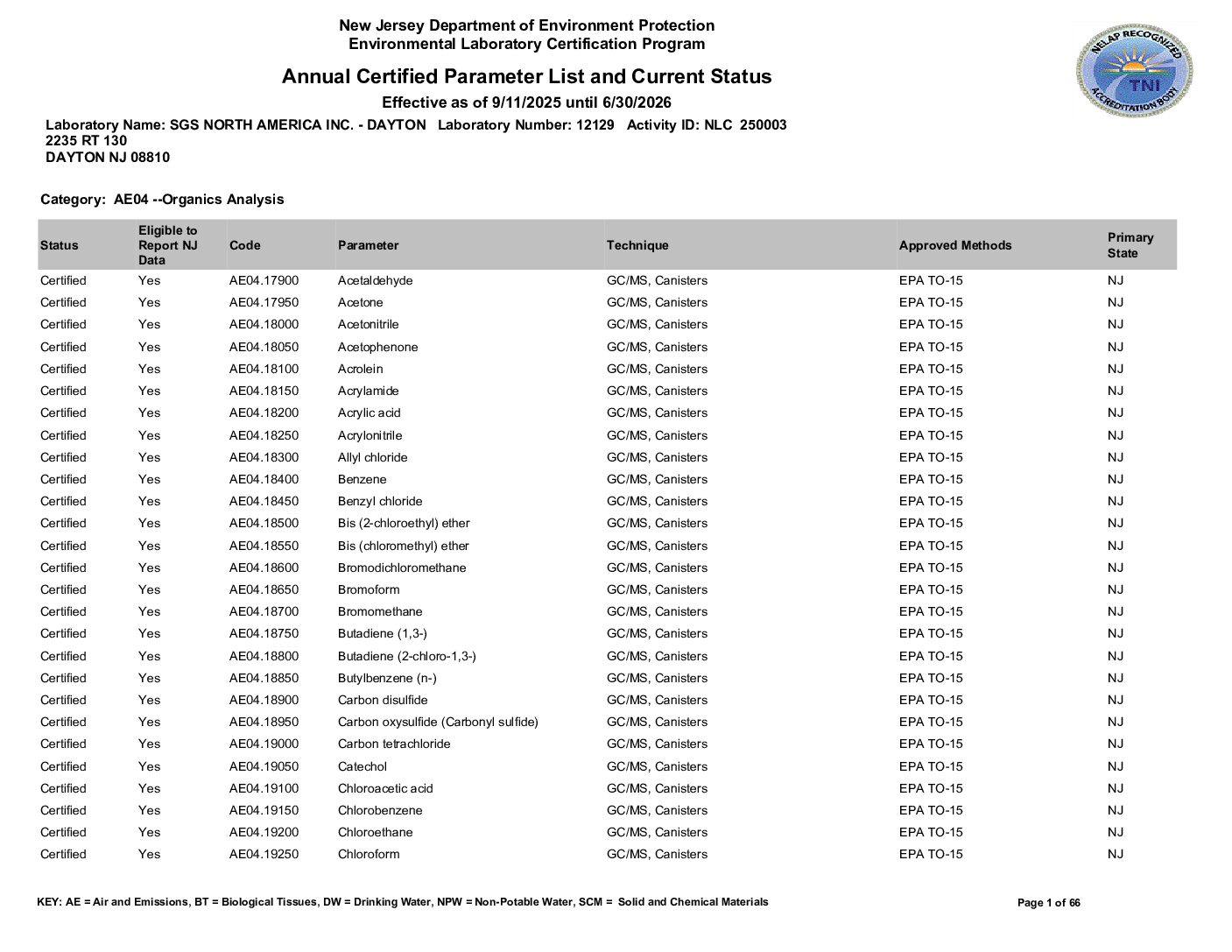

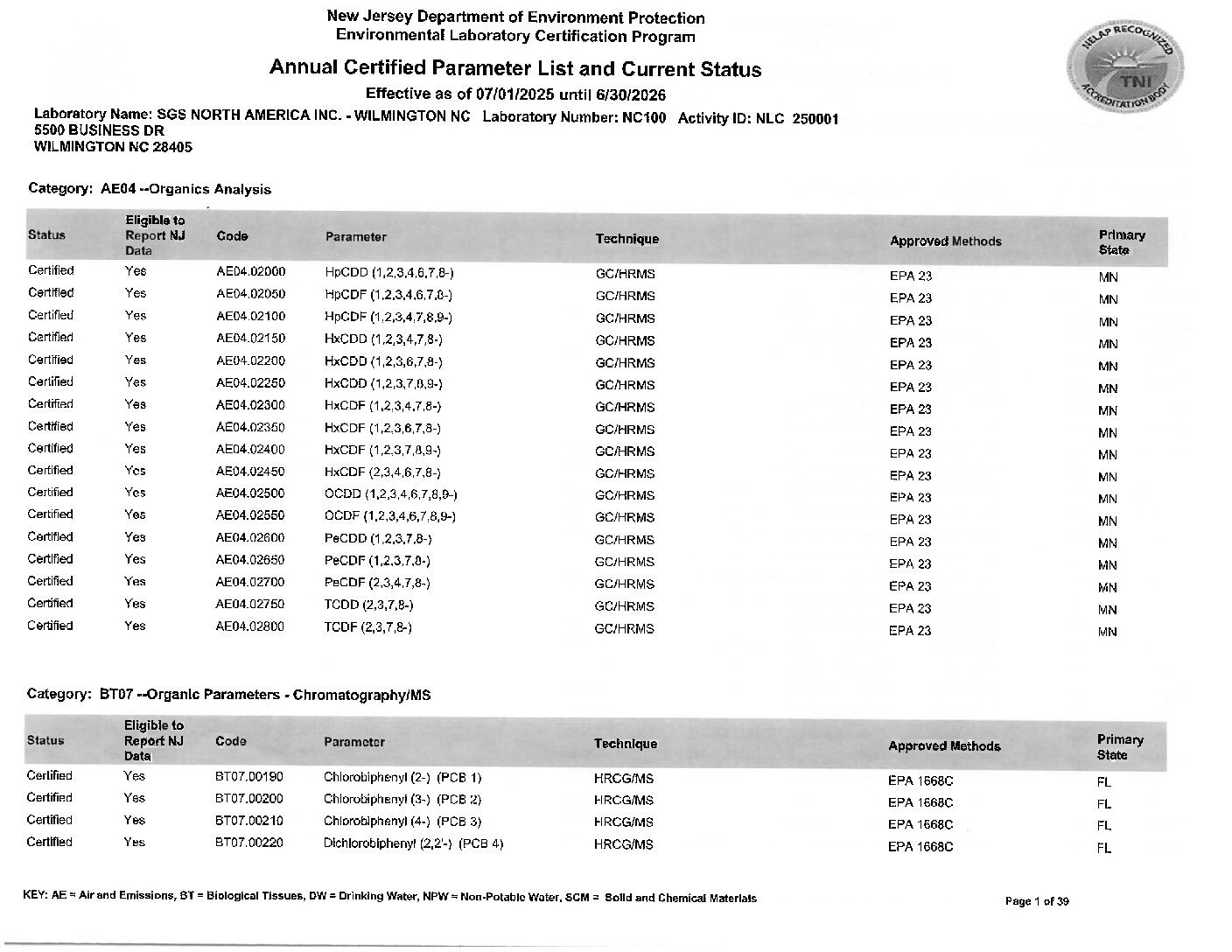

| Dayton, NJ | SGS Dayton New Jersey | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | air-quality environmental-testing pfas-analysis | new-jersey | dayton-nj | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

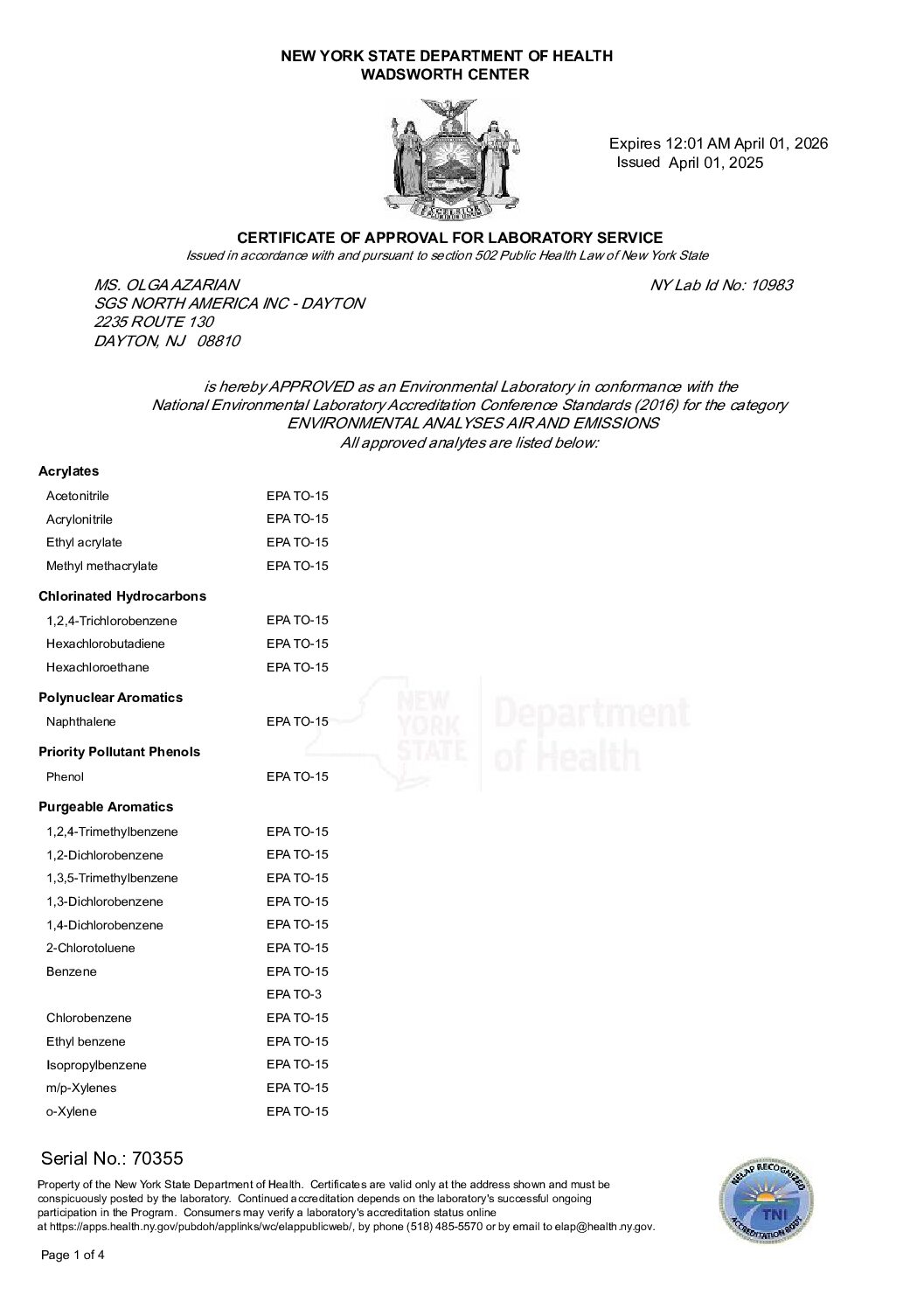

| Dayton, NJ | SGS Dayton New York | TNI/NELAP | New York State Department of Health (NY DOH) | air-quality environmental-testing pfas-analysis | new-york | dayton-nj | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Dayton, NJ | SGS Dayton North Carolina | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | air-quality environmental-testing pfas-analysis | dayton-nj | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

| Dayton, NJ | SGS Dayton Oregon | TNI/NELAP | Oregon Laboratory Accreditation Program (ORELAP) | air-quality environmental-testing pfas-analysis | oregon | dayton-nj | tni-nelap | oregon-laboratory-accreditation-program-orelap | ||

| Dayton, NJ | SGS Dayton Pennsylvania | TNI/NELAP | Pennsylvania Department of Environmental Protection (PA DEP) | air-quality environmental-testing pfas-analysis | pennsylvania | dayton-nj | tni-nelap | pennsylvania-department-of-environmental-protection-pa-dep | ||

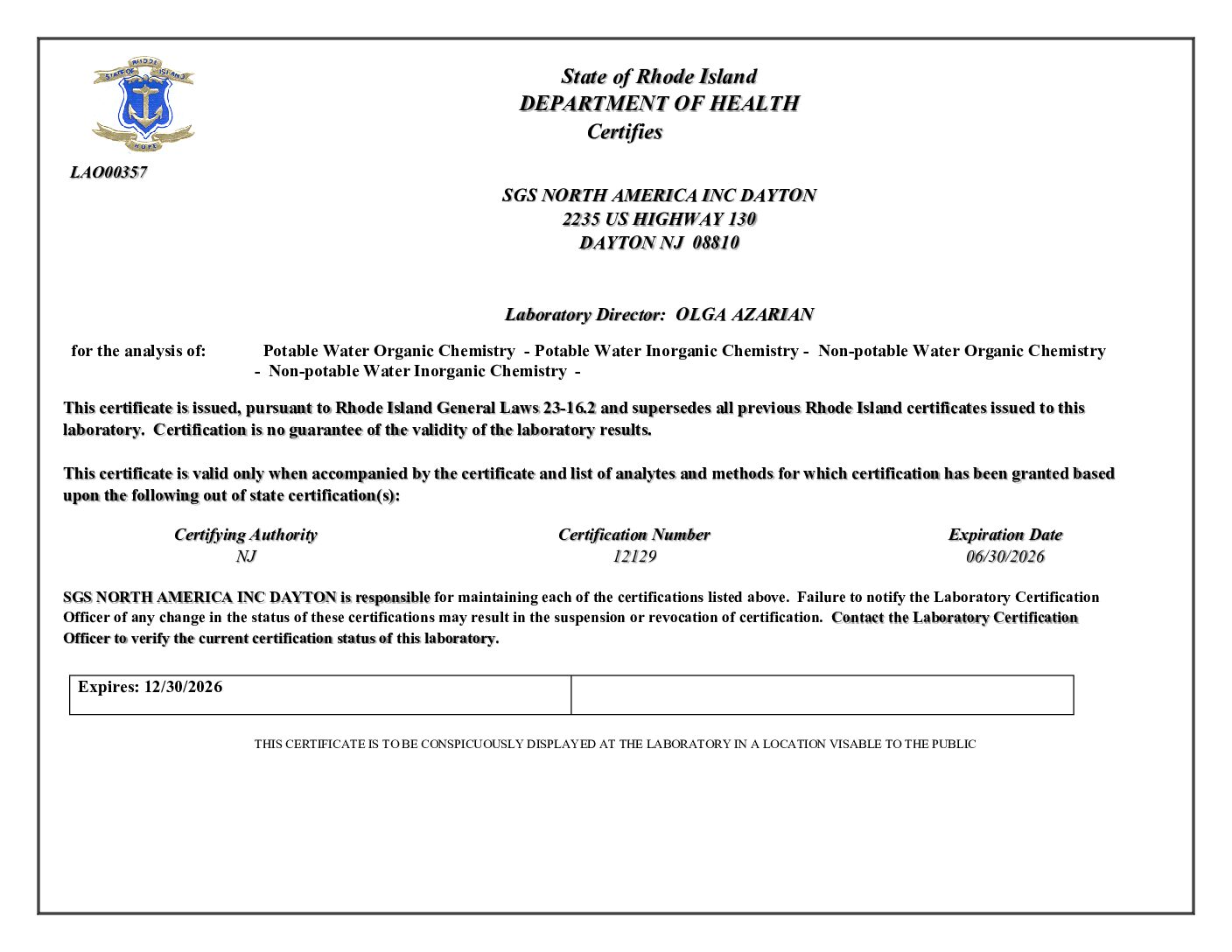

| Dayton, NJ | SGS Dayton Rhode Island | Non-NELAP States | Rhode Island Department of Health (RIDOH) | air-quality environmental-testing pfas-analysis | rhode-island | dayton-nj | non-nelap-states | rhode-island-department-of-health-ridoh | ||

| Dayton, NJ | SGS Dayton South Carolina | Non-NELAP States | South Carolina Environmental Laboratory Certification Program (SC ELCP) | air-quality environmental-testing pfas-analysis | south-carolina | dayton-nj | non-nelap-states | south-carolina-environmental-laboratory-certification-program-sc-elcp | ||

| Dayton, NJ | SGS Dayton Texas | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | air-quality environmental-testing pfas-analysis | texas | dayton-nj | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Dayton, NJ | SGS Dayton Utah | TNI/NELAP | Utah Department of Health and Human Services (UT DHHS) | air-quality environmental-testing pfas-analysis | utah | dayton-nj | tni-nelap | utah-department-of-health-and-human-services-ut-dhhs | ||

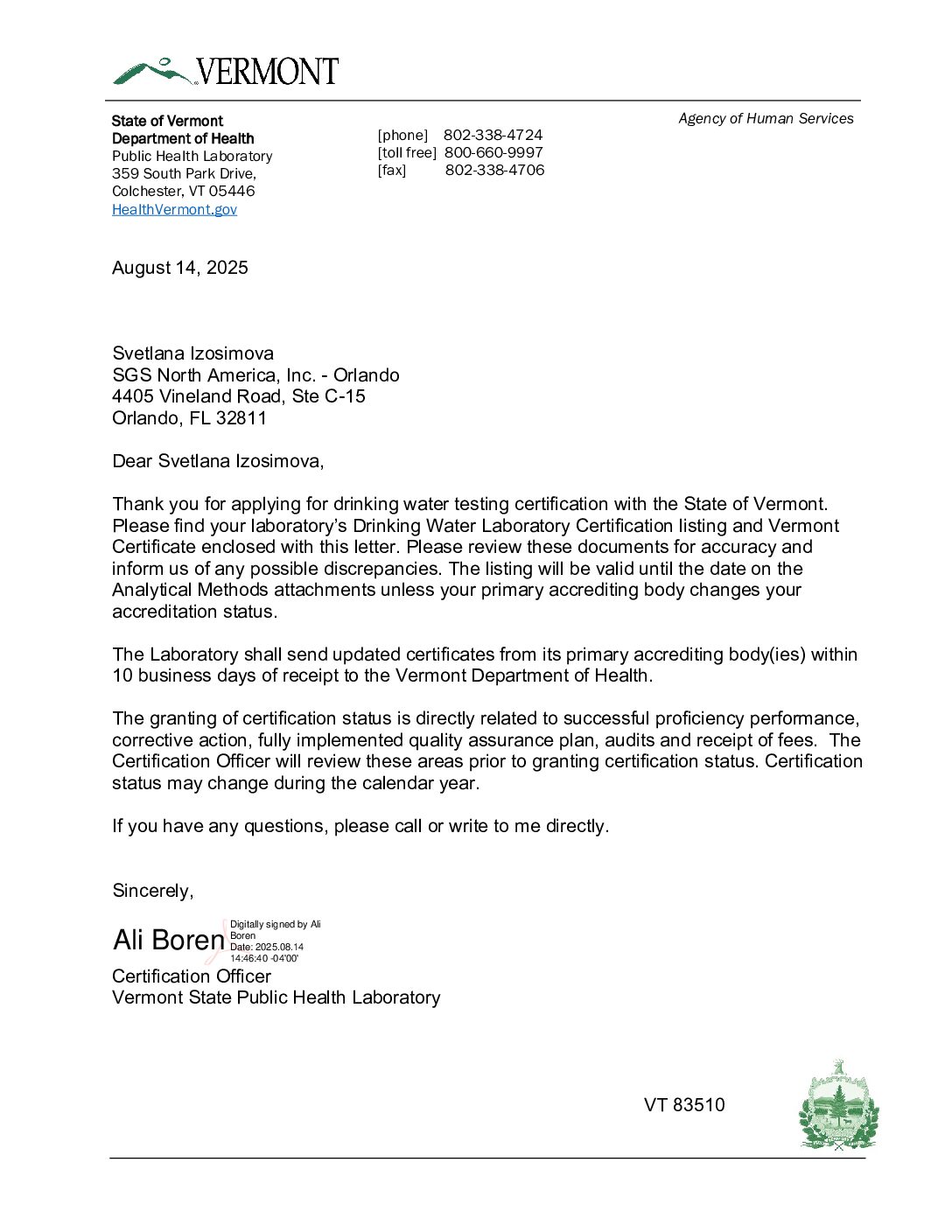

| Dayton, NJ | SGS Dayton Vermont | Non-NELAP States | State of Vermont, Department of Health (VT DOH) | air-quality environmental-testing pfas-analysis | vermont | dayton-nj | non-nelap-states | state-of-vermont-department-of-health-vt-doh | ||

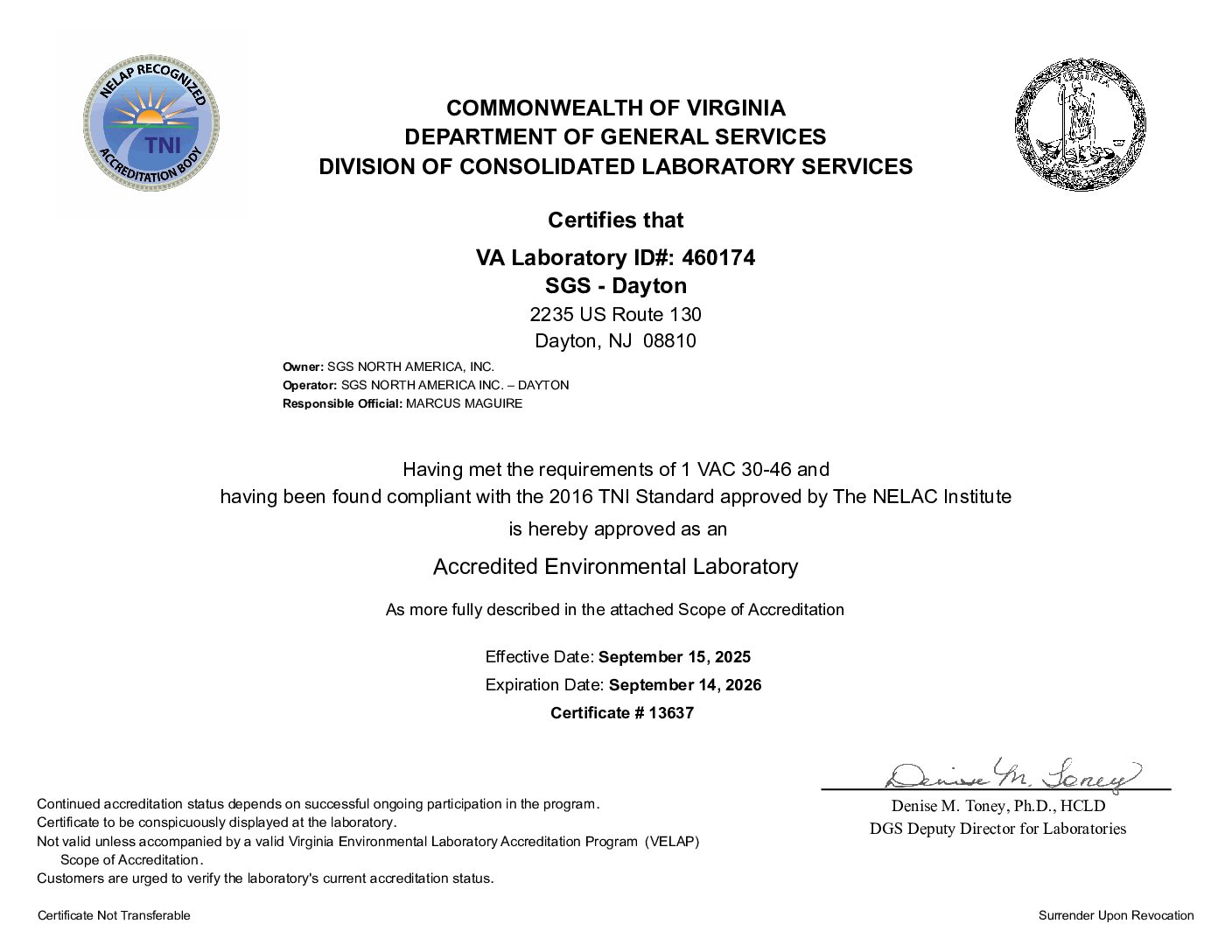

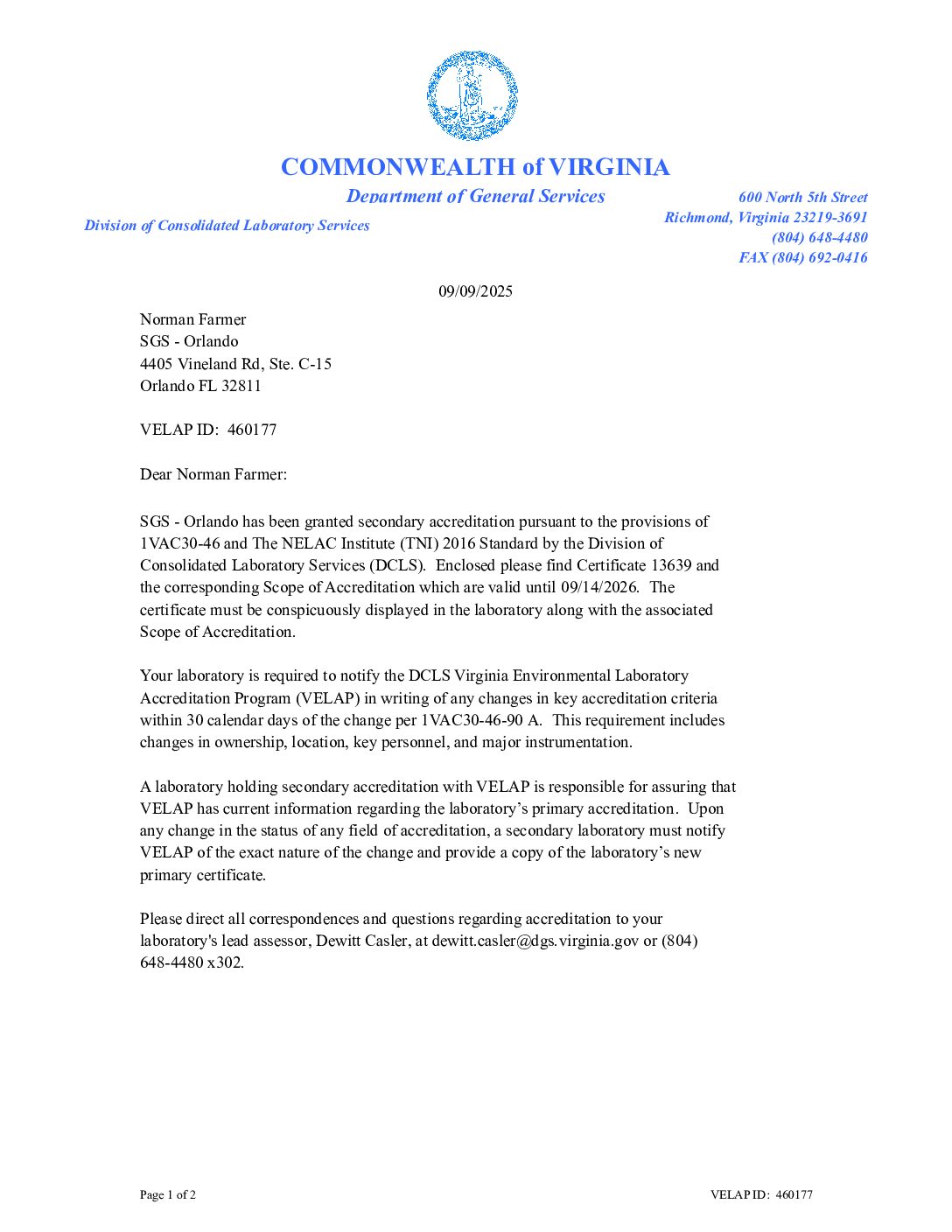

| Dayton, NJ | SGS Dayton Virginia | TNI/NELAP | Virginia Department of General Services (VA DGS) | air-quality environmental-testing pfas-analysis | virginia | dayton-nj | tni-nelap | virginia-department-of-general-services-va-dgs | ||

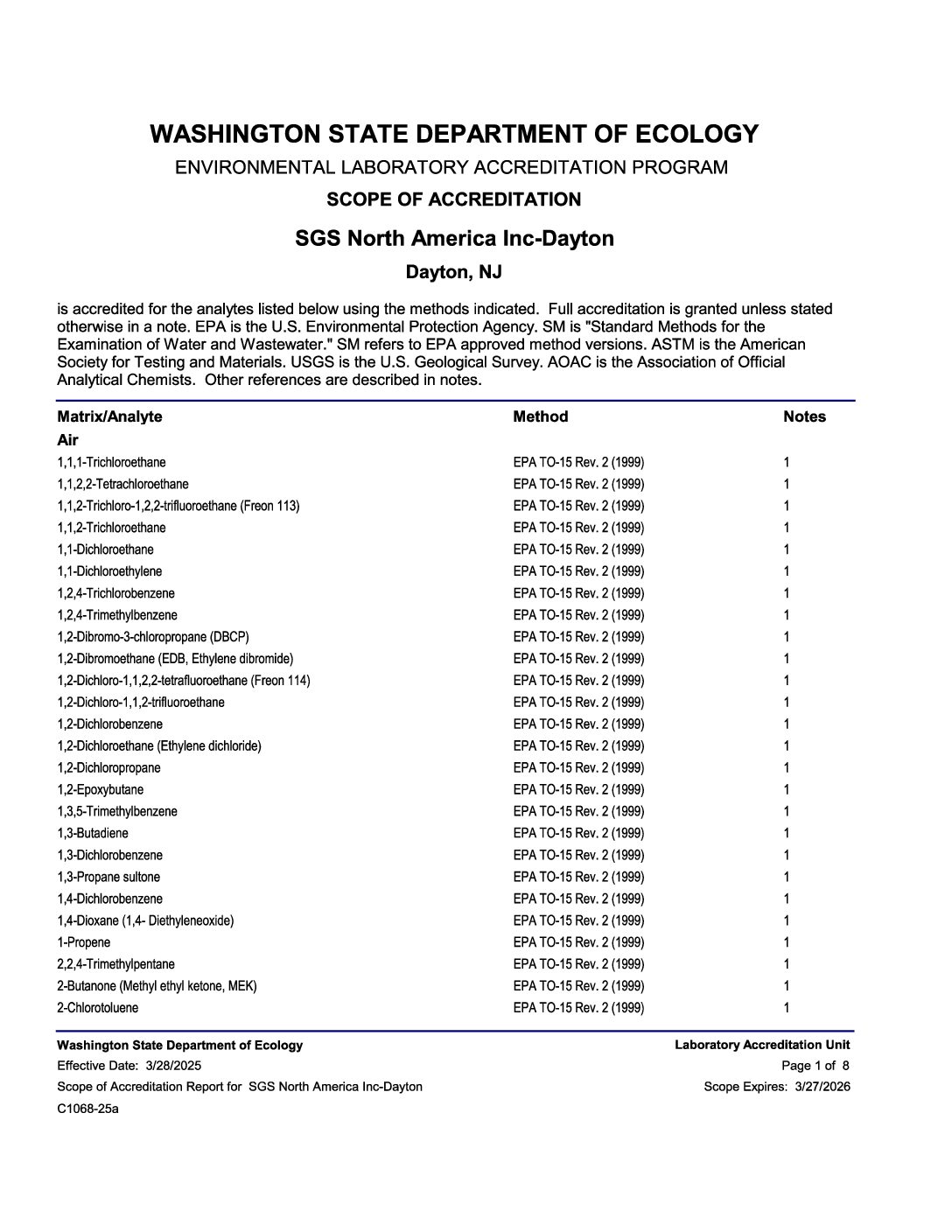

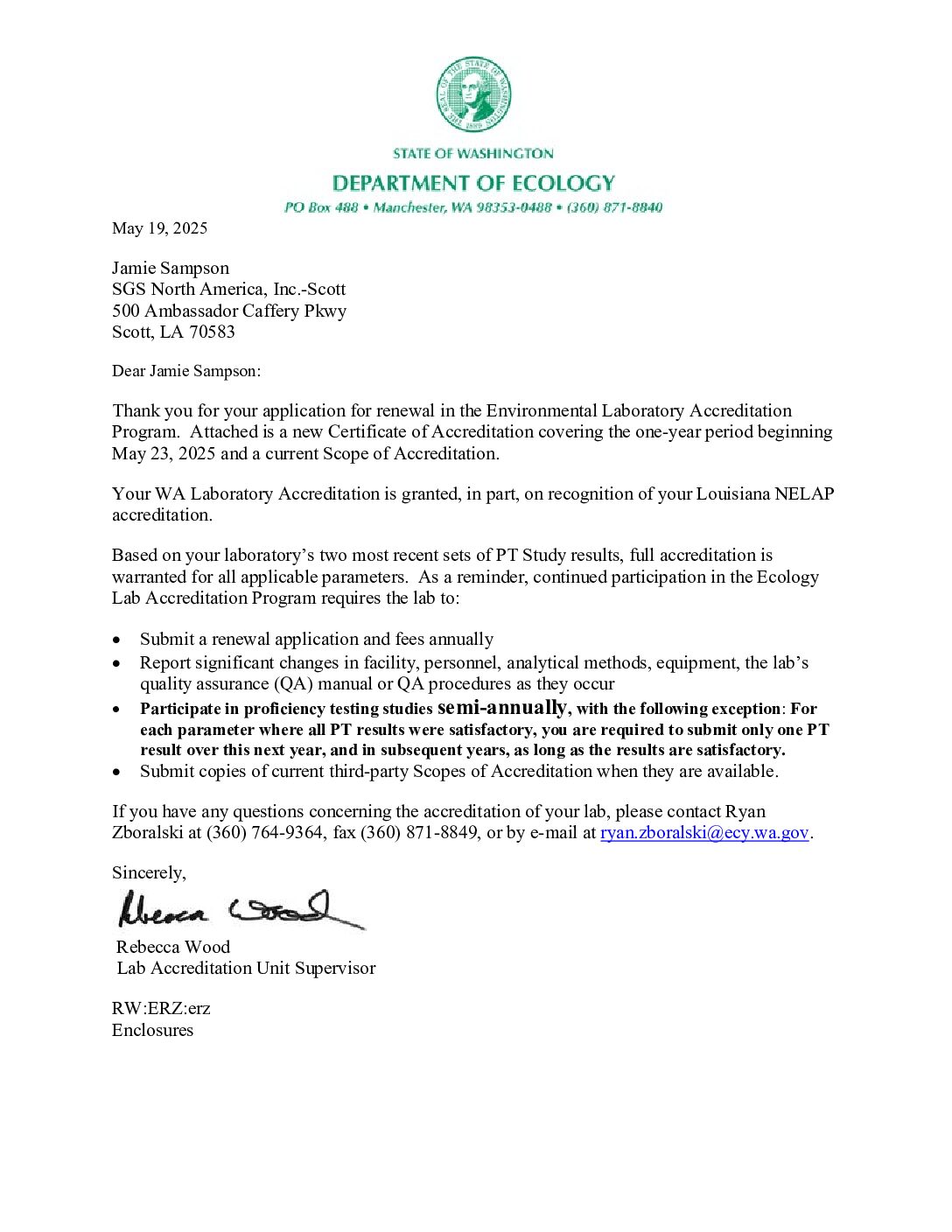

| Dayton, NJ | SGS Dayton Washington | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | air-quality environmental-testing pfas-analysis | washington | dayton-nj | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

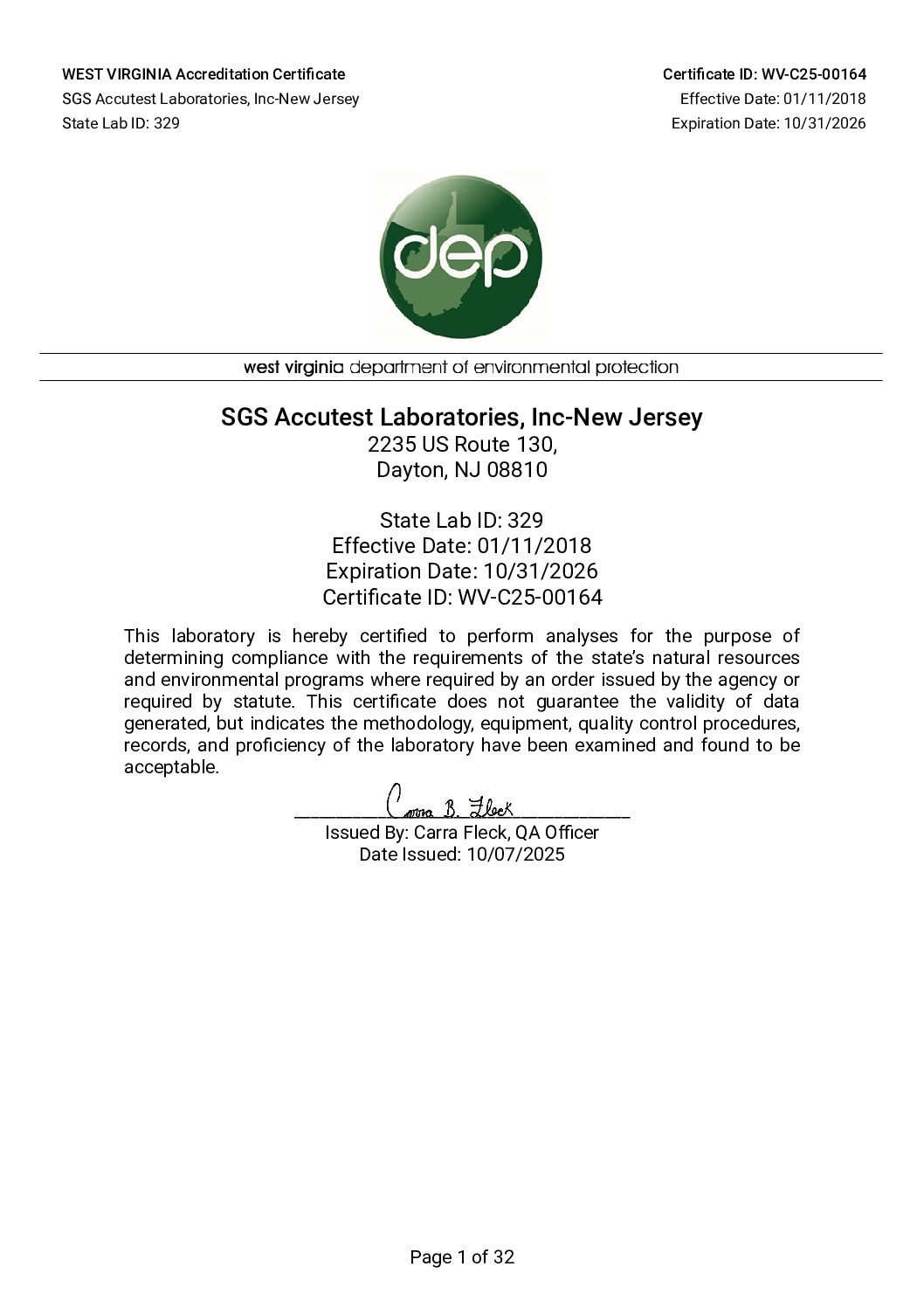

| Dayton, NJ | SGS Dayton West Virginia | Non-NELAP States | West Virginia Department of Environmental Protection (WV DEP) | air-quality environmental-testing pfas-analysis | west-virginia | dayton-nj | non-nelap-states | west-virginia-department-of-environmental-protection-wv-dep | ||

| Downers Grove, IL | SGS Downers Grove NVLAP | ISO/IEC 17025:2017, NVLAP | United States Department of Commerce National Institute of Standards & Technology | built-environment | not-applicable | downers-grove-il | iso-iec-170252017 nvlap | united-states-department-of-commerce-national-institute-of-standards-technology | ||

| Downers Grove, IL | SGS Downers Grove Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | built-environment | arizona | downers-grove-il | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

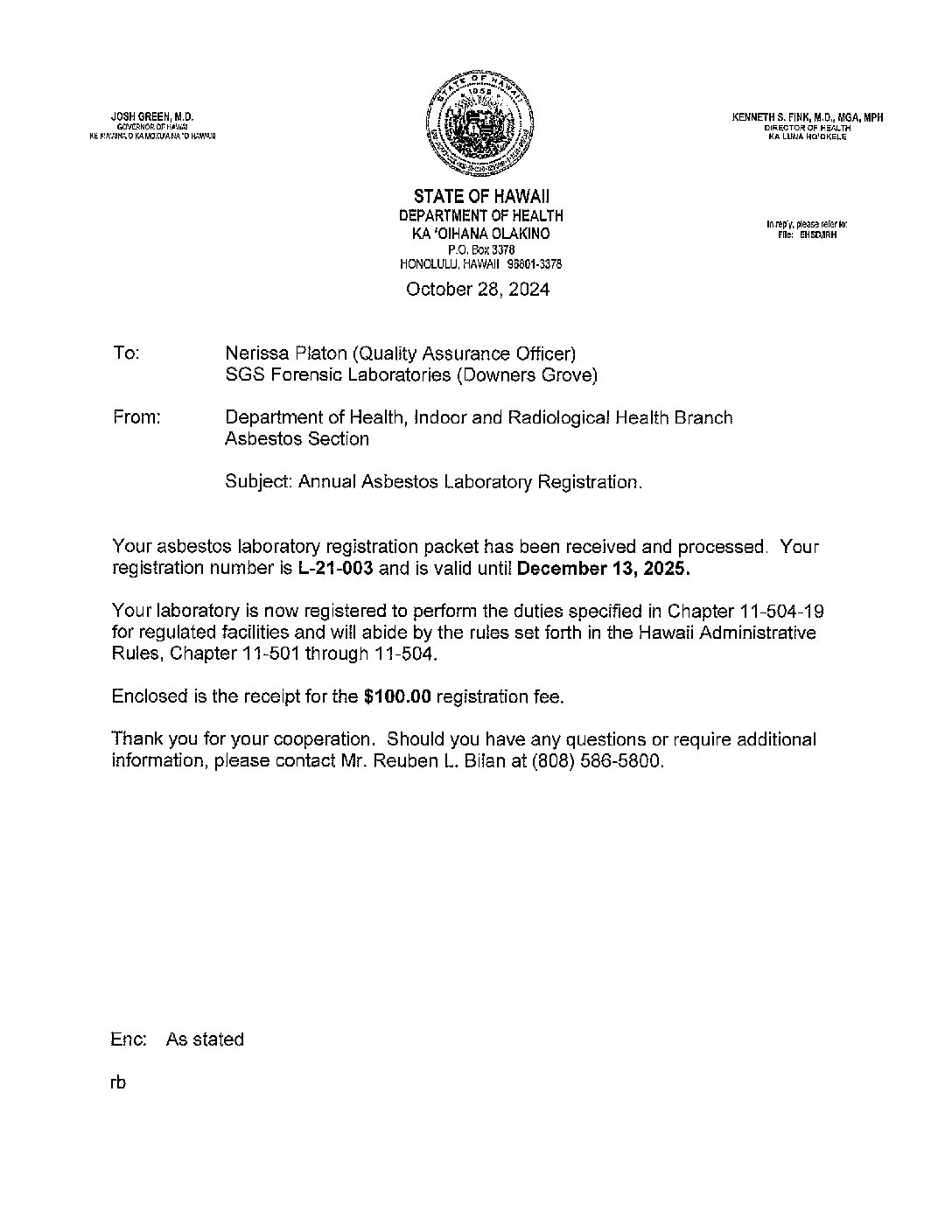

| Downers Grove, IL | SGS Downers Grove Hawaii | Drinking Water | State of Hawaii Department of Health (HI DOH) | built-environment | hawaii | downers-grove-il | drinking-water | state-of-hawaii-department-of-health-hi-doh | ||

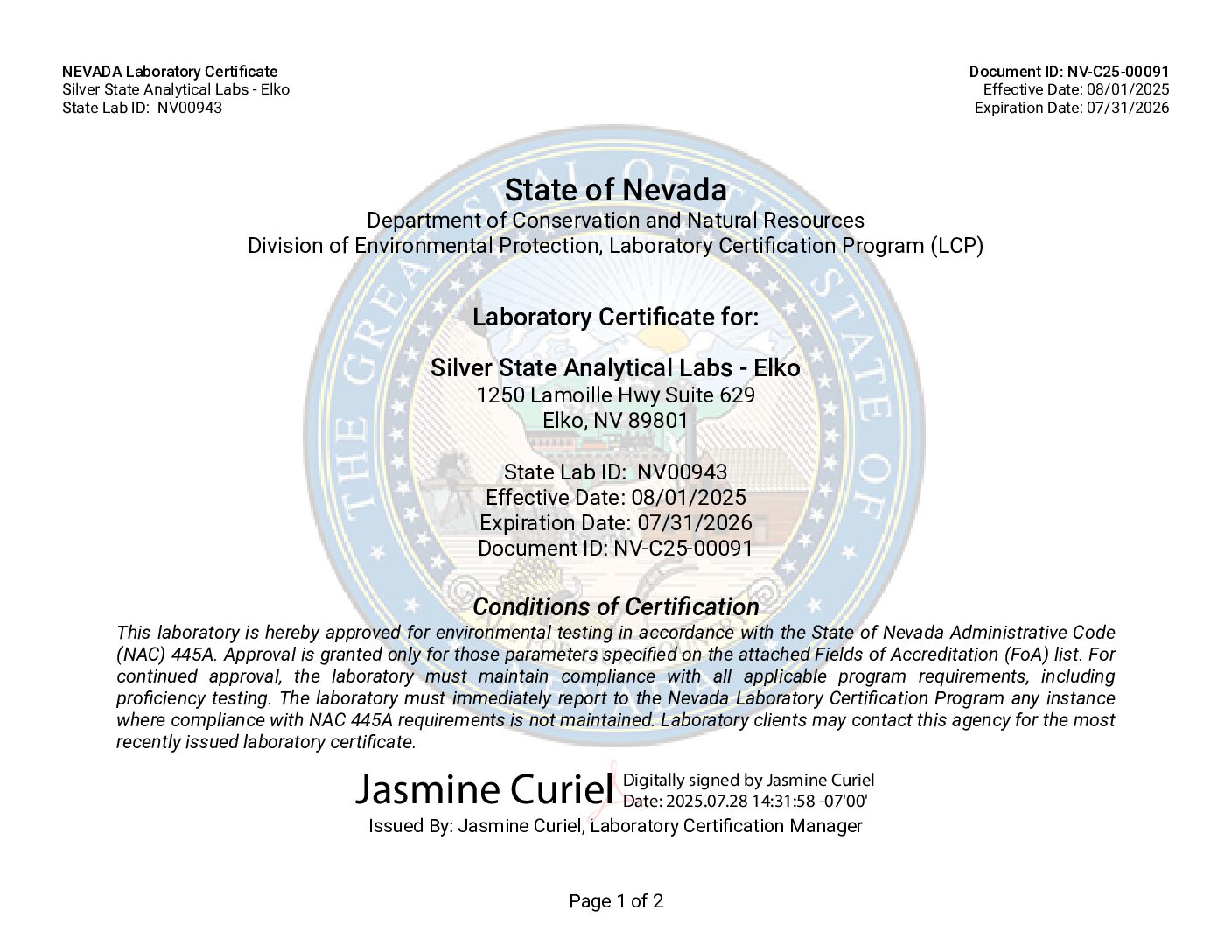

| Elko, NV | SGS Elko NV | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing mining | nevada | elko-nv | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Hayward, CA | SGS Hayward NVLAP | ISO/IEC 17025:2017, NVLAP | United States Department of Commerce National Institute of Standards & Technology | built-environment | not-applicable | hayward-ca | iso-iec-170252017 nvlap | united-states-department-of-commerce-national-institute-of-standards-technology | ||

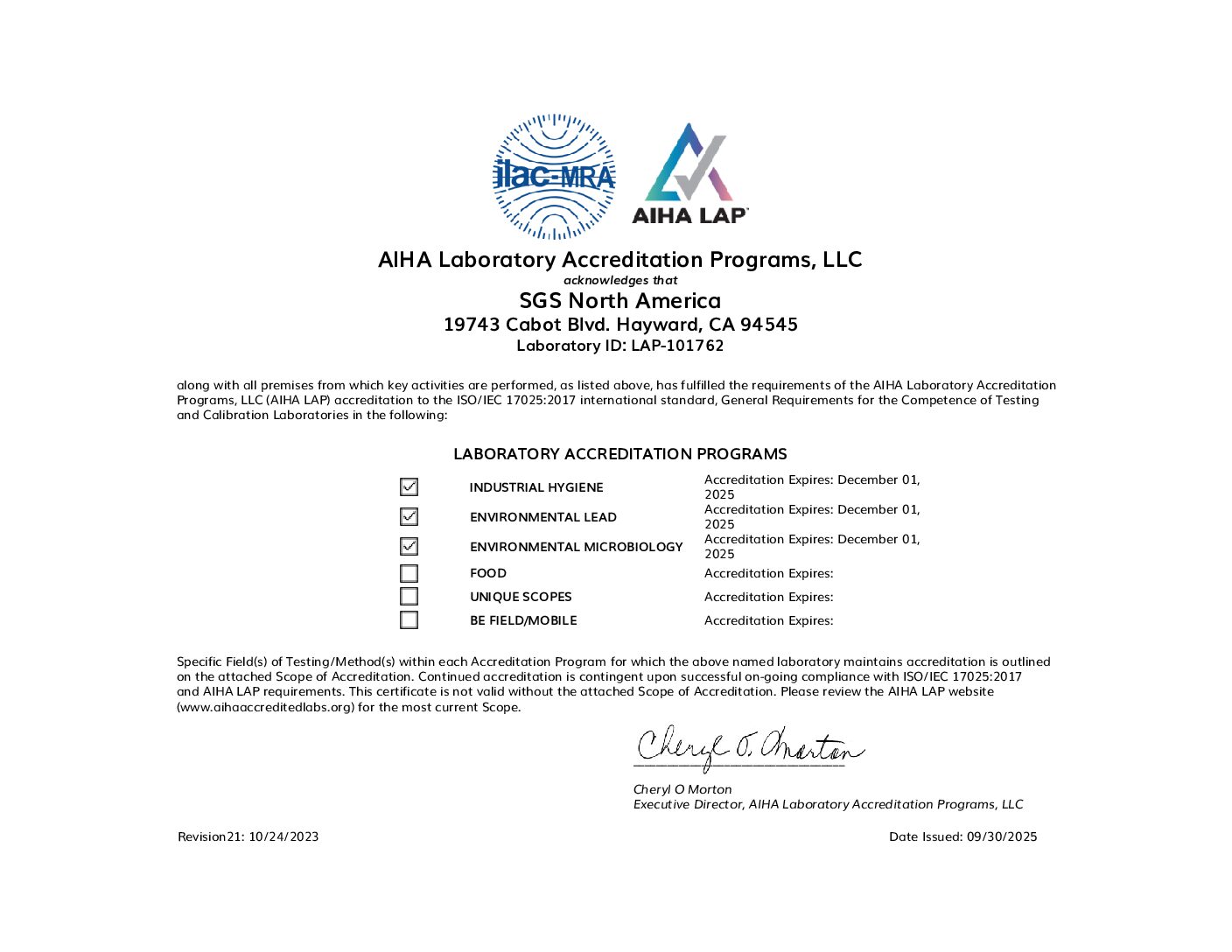

| Hayward, CA | SGS Hayward AIHA | AIHA, ISO/IEC 17025:2017 | AIHA Laboratory Accreditation Program (AIHA LAP) | built-environment | not-applicable | hayward-ca | aiha iso-iec-170252017 | aiha-laboratory-accreditation-program-aiha-lap | ||

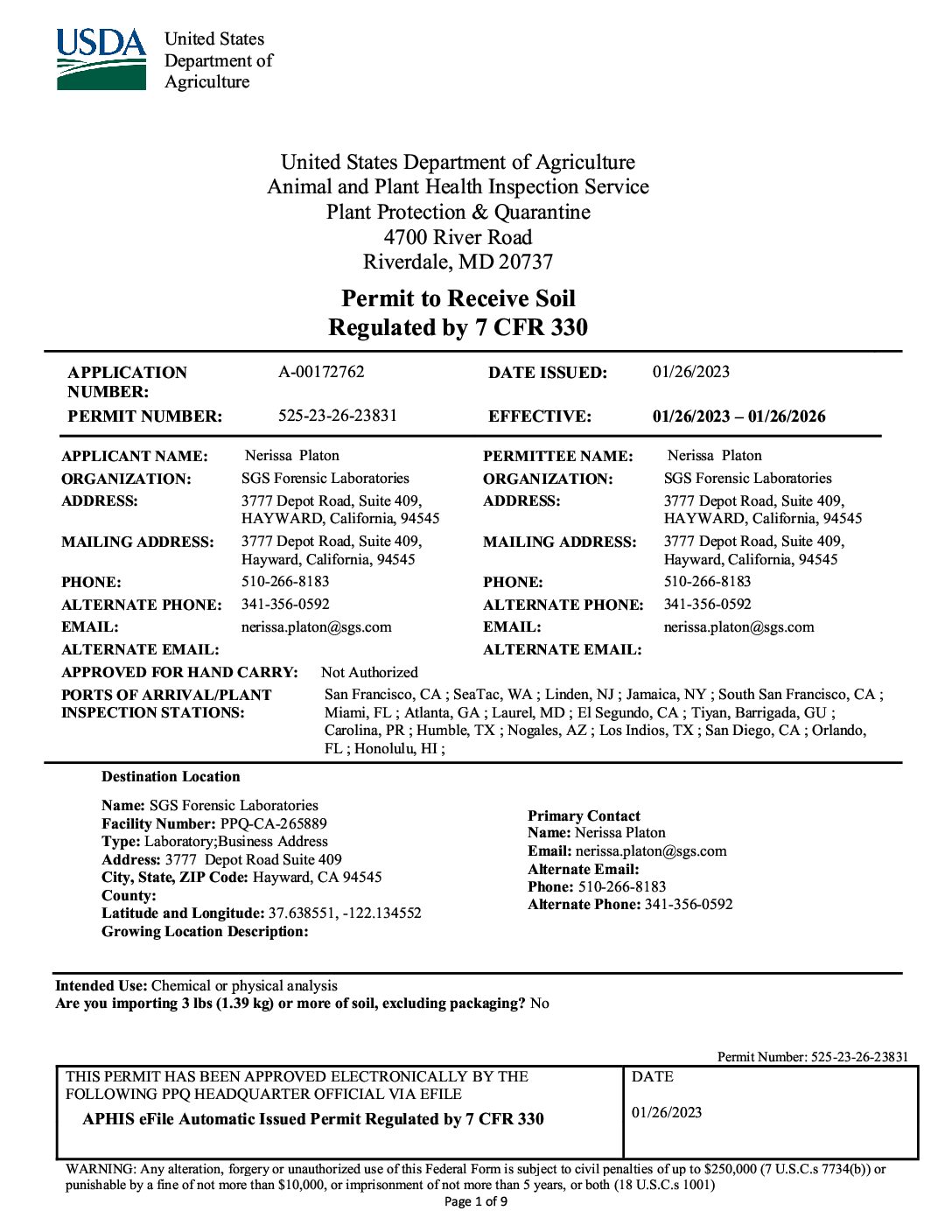

| Hayward, CA | SGS Hayward USDA | Foreign Soil | USDA | built-environment | not-applicable | hayward-ca | foreign-soil | usda | ||

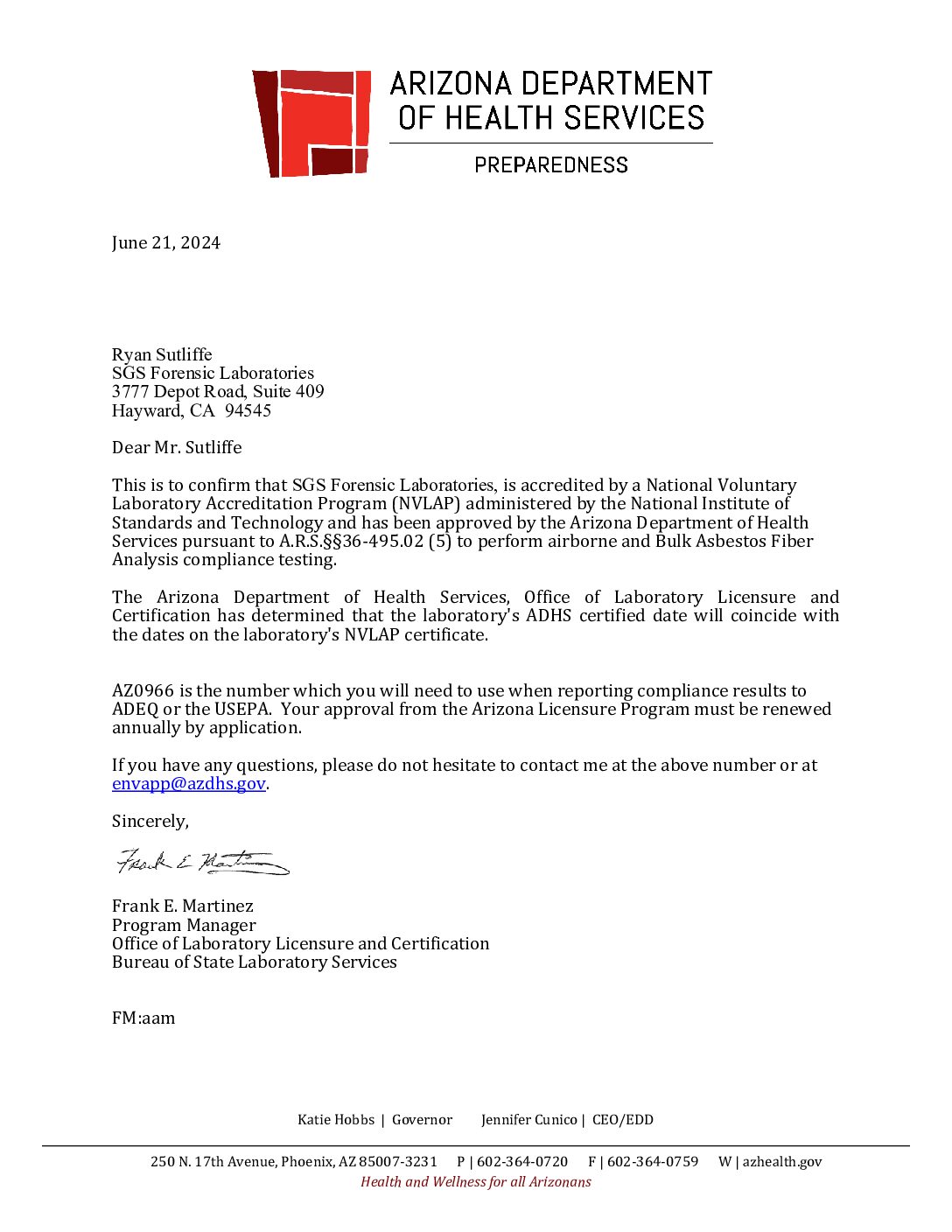

| Hayward, CA | SGS Hayward Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | built-environment | arizona | hayward-ca | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

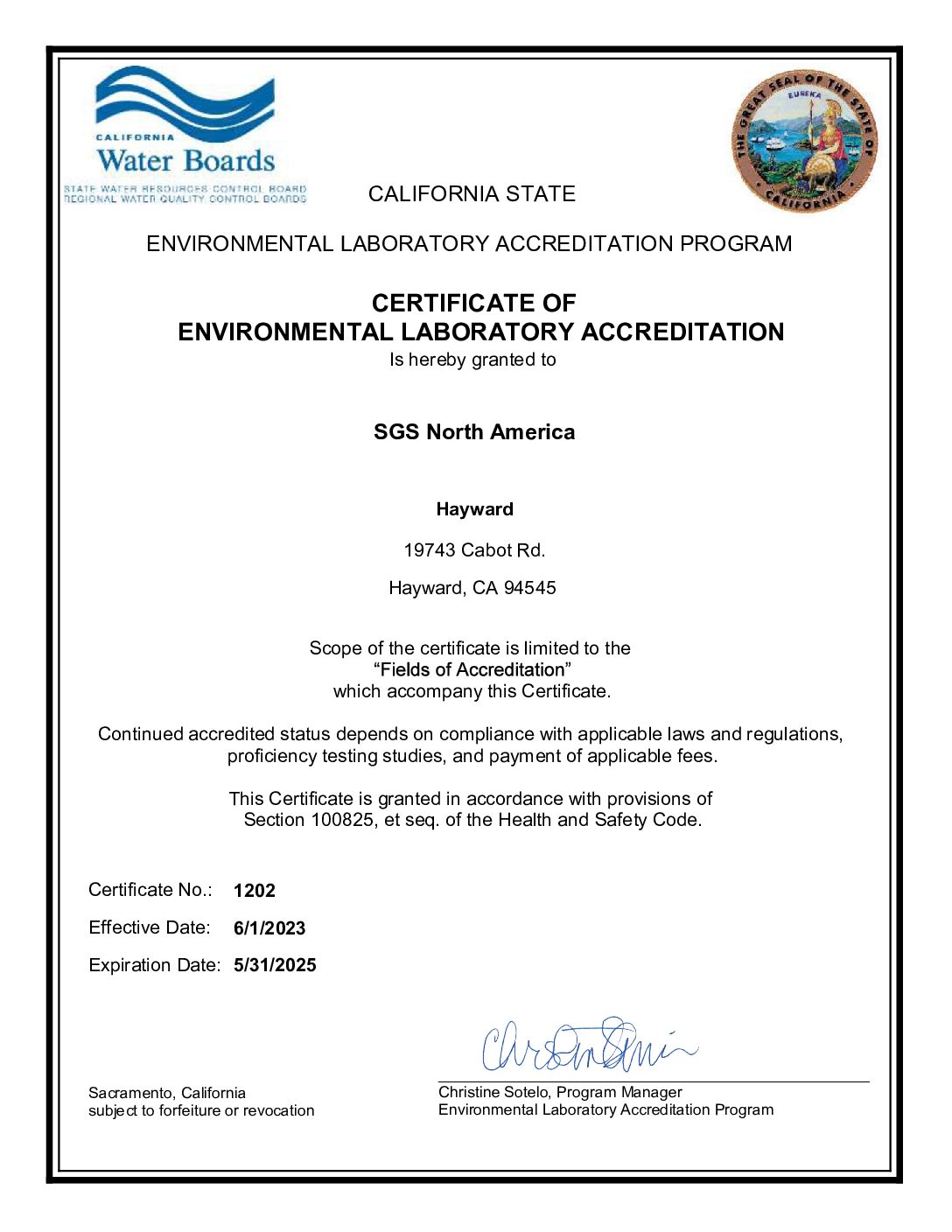

| Hayward, CA | SGS Hayward California | TNI - 2 (California) | California Waterboards | built-environment | california | hayward-ca | tni-2-california | california-waterboards | ||

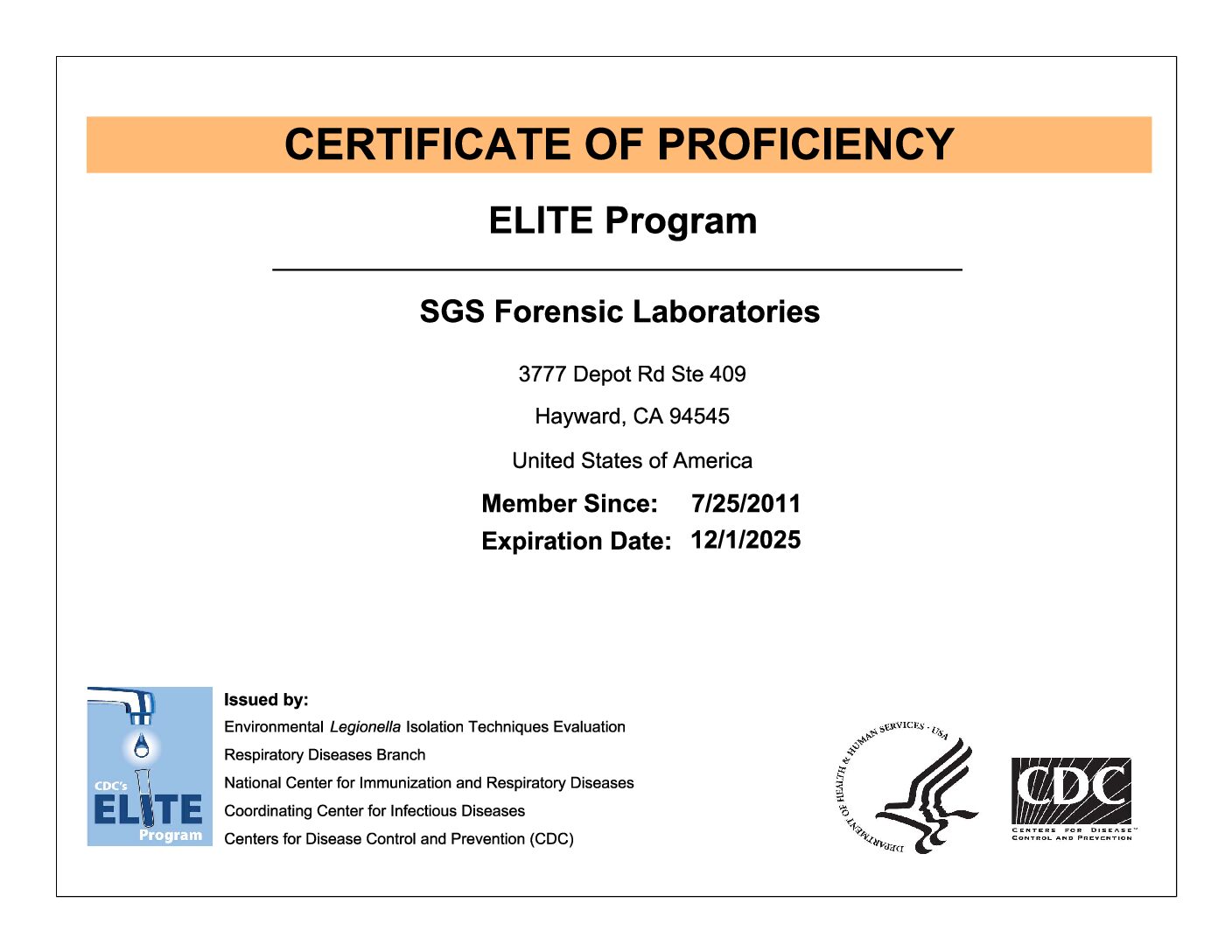

| Hayward, CA | SGS Hayward CDC ELITE | Other | Centers for Disease Control and Prevention (CDC) | built-environment | california | hayward-ca | other | centers-for-disease-control-and-prevention-cdc | ||

| Hayward, CA | SGS Hayward Colorado | Drinking Water | Colorado Department of Public Health and Environment (CODPHE) | built-environment | colorado | hayward-ca | drinking-water | colorado-department-of-public-health-and-environment-codphe | ||

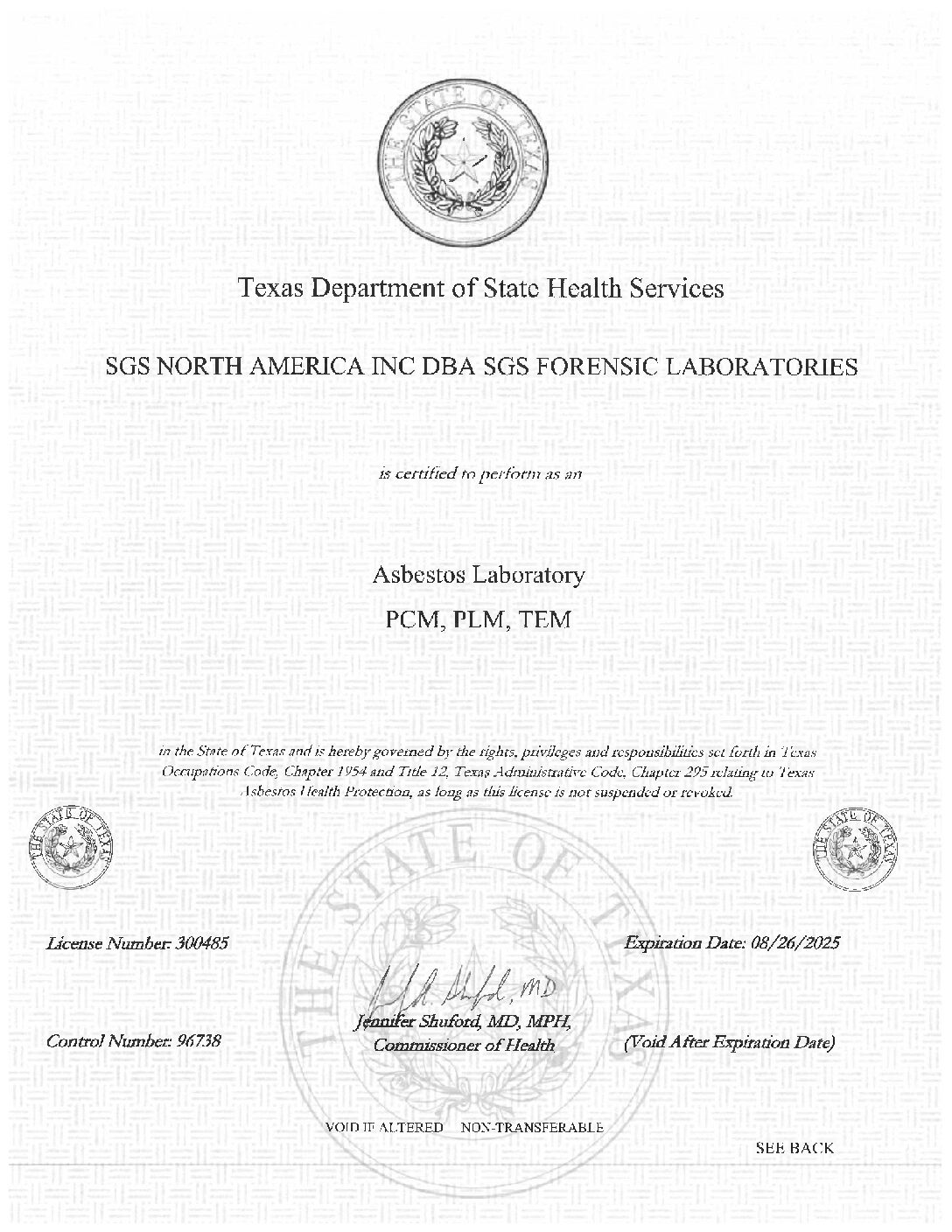

| Hayward, CA | SGS Hayward Texas Asbestos | Other | Texas Department of State Health Services (TX DSHS) | built-environment | texas | hayward-ca | other | texas-department-of-state-health-services-tx-dshs | ||

| Houston, TX | SGS Houston AK | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | air-quality | alaska | houston-tx | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

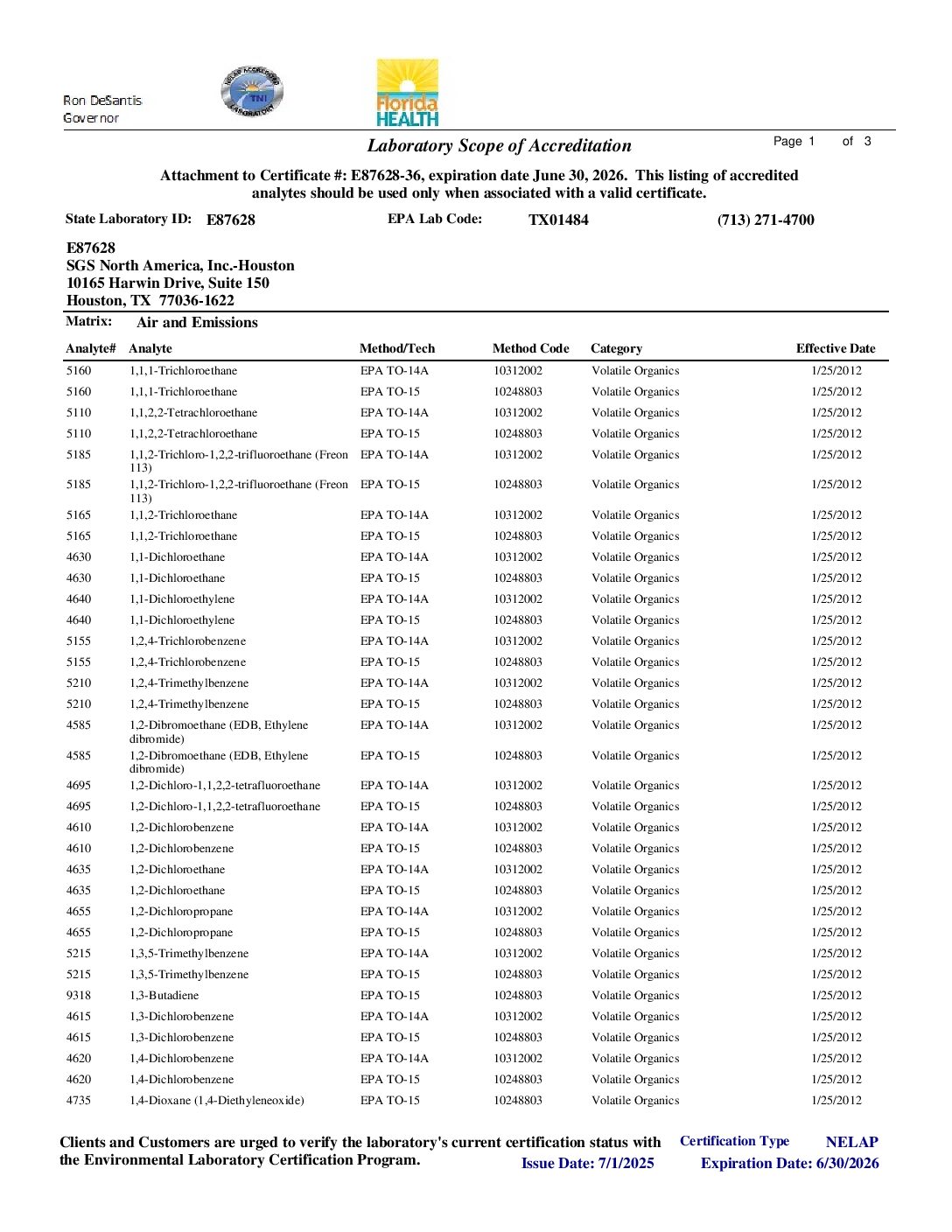

| Houston, TX | SGS Houston FL | TNI/NELAP | Florida Department of Health (FL DOH) | air-quality | florida | houston-tx | tni-nelap | florida-department-of-health-fl-doh | ||

| Houston, TX | SGS Houston LA | TNI/NELAP | Louisiana Department of Environmental Quality (LDEQ) | air-quality | louisiana | houston-tx | tni-nelap | louisiana-department-of-environmental-quality-ldeq | ||

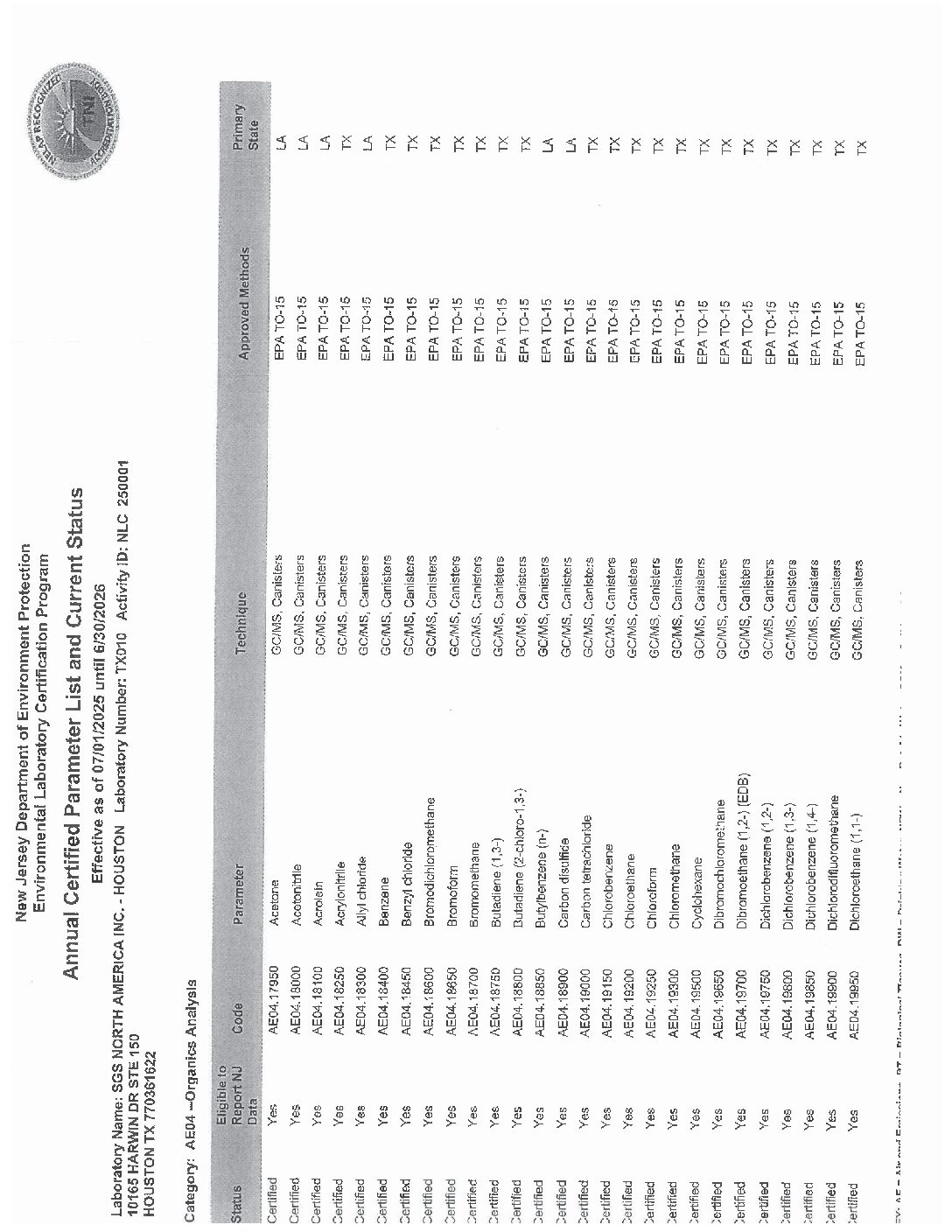

| Houston, TX | SGS Houston NJ | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | air-quality | new-jersey | houston-tx | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

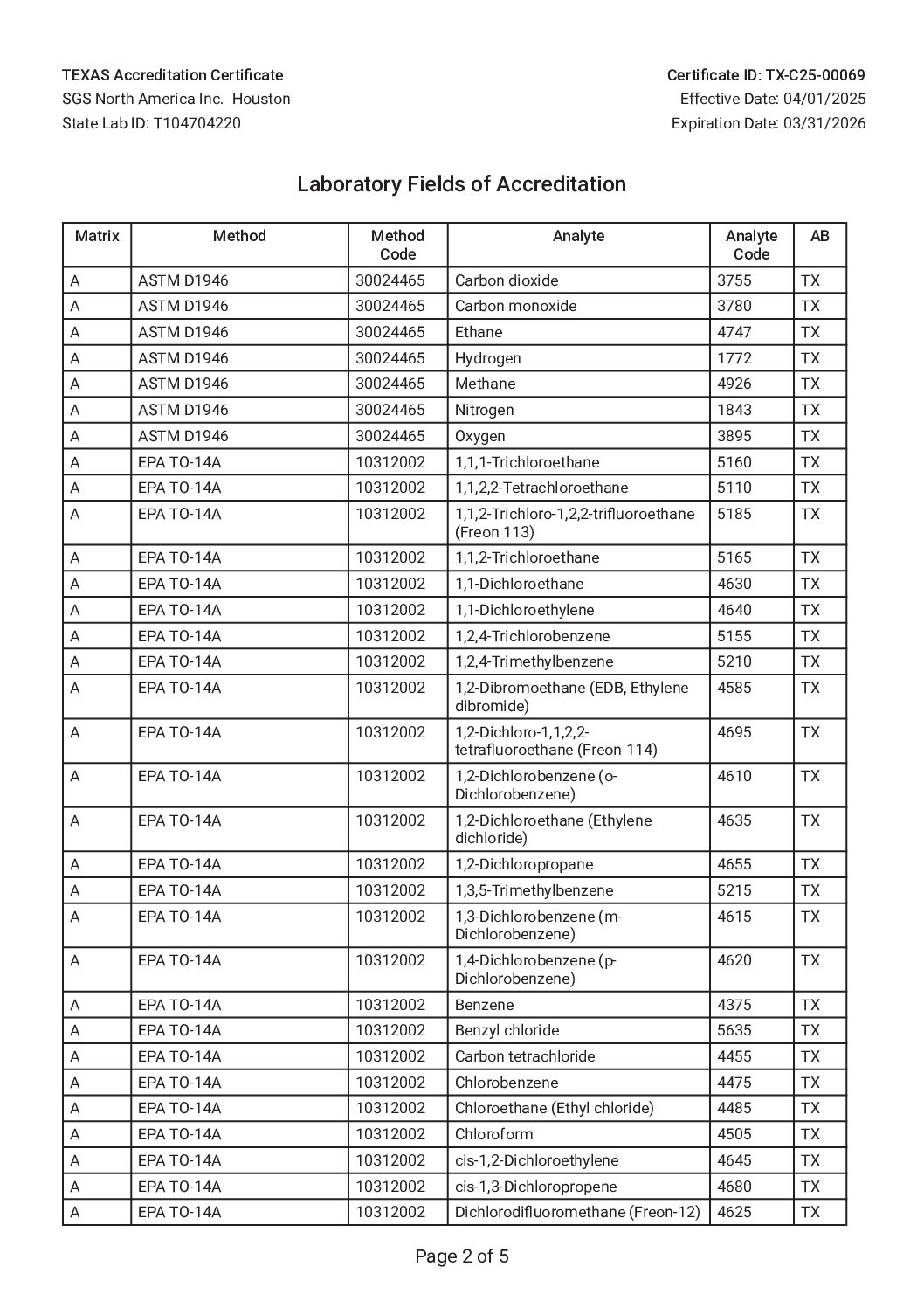

| Houston, TX | SGS Houston TX | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | air-quality | texas | houston-tx | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Houston, TX | SGS Houston VA | TNI/NELAP | Virginia Department of General Services (VA DGS) | air-quality | virginia | houston-tx | tni-nelap | virginia-department-of-general-services-va-dgs | ||

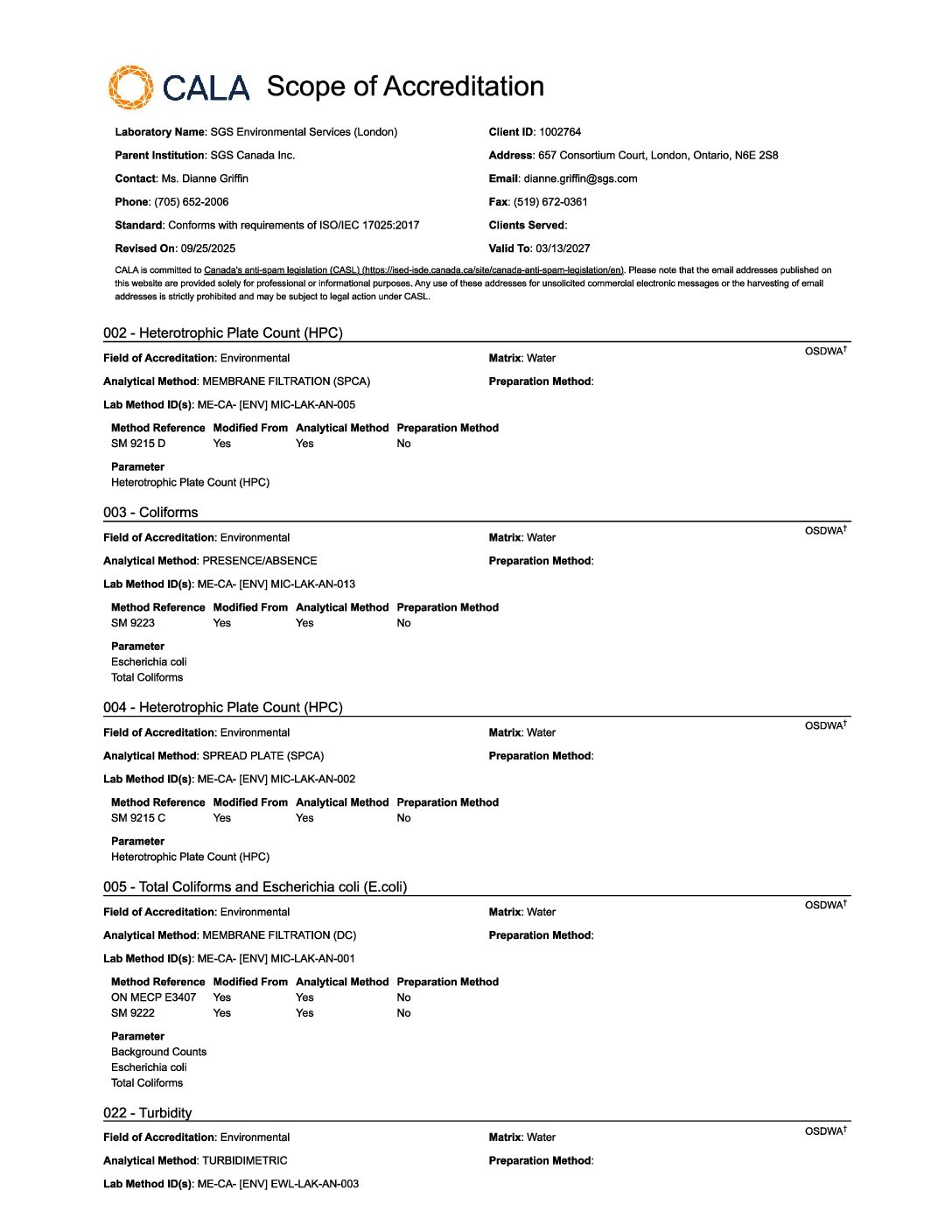

| Lakefield, ON | SGS Lakefield Ontario | ISO/IEC 17025:2017 | Canadian Association for Laboratory Accreditation (CALA) | air-quality environmental-testing mining pfas-analysis radiochemistry | canada ontario | lakefield-on | iso-iec-170252017 | canadian-association-for-laboratory-accreditation-cala | ||

| Lanham, MD | SGS Lanham AIHA | AIHA, ISO/IEC 17025:2017 | AIHA Laboratory Accreditation Program (AIHA LAP) | environmental-testing industrial-hygiene | not-applicable | lanham-md | aiha iso-iec-170252017 | aiha-laboratory-accreditation-program-aiha-lap | ||

| Lanham, MD | SGS Lanham Maryland | Non-NELAP States | Maryland Department of the Environment Water Supply Program (MD DOE) | environmental-testing industrial-hygiene | maryland | lanham-md | non-nelap-states | maryland-department-of-the-environment-water-supply-program-md-doe | ||

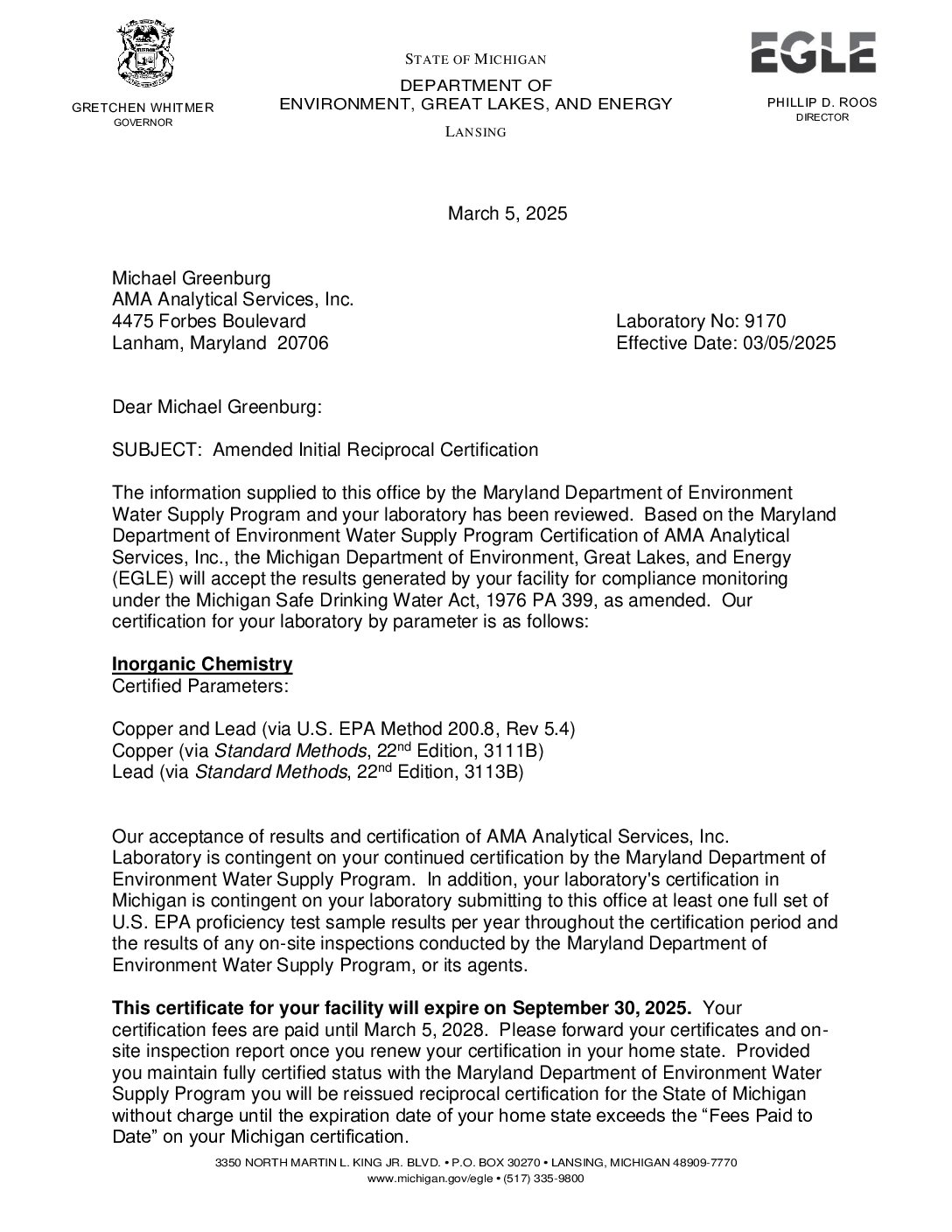

| Lanham, MD | SGS Lanham Michigan | Drinking Water | Michigan Department of Environment, Great Lakes, and Energy (MI EGLE) | environmental-testing industrial-hygiene | michigan | lanham-md | drinking-water | michigan-department-of-environment-great-lakes-and-energy-mi-egle | ||

| Lanham, MD | SGS Lanham New York | TNI/NELAP | New York State Department of Health (NY DOH) | environmental-testing industrial-hygiene | new-york | lanham-md | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Lanham, MD | SGS Lanham New York | TNI/NELAP | New York State Department of Health (NY DOH) | environmental-testing industrial-hygiene | new-york | lanham-md | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Lanham, MD | SGS Lanham Puerto Rico | Drinking Water | Puerto Rico Department of Health (PR DOH) | environmental-testing industrial-hygiene | puerto-rico | lanham-md | drinking-water | puerto-rico-department-of-health-pr-doh | ||

| Lanham, MD | SGS Lanham Virginia Asbestos | Other | Virginia Board of Asbestos, Lead, and Home Inspectors (VA DPOR) | environmental-testing industrial-hygiene | virginia | lanham-md | other | virginia-board-of-asbestos-lead-and-home-inspectors-va-dpor | ||

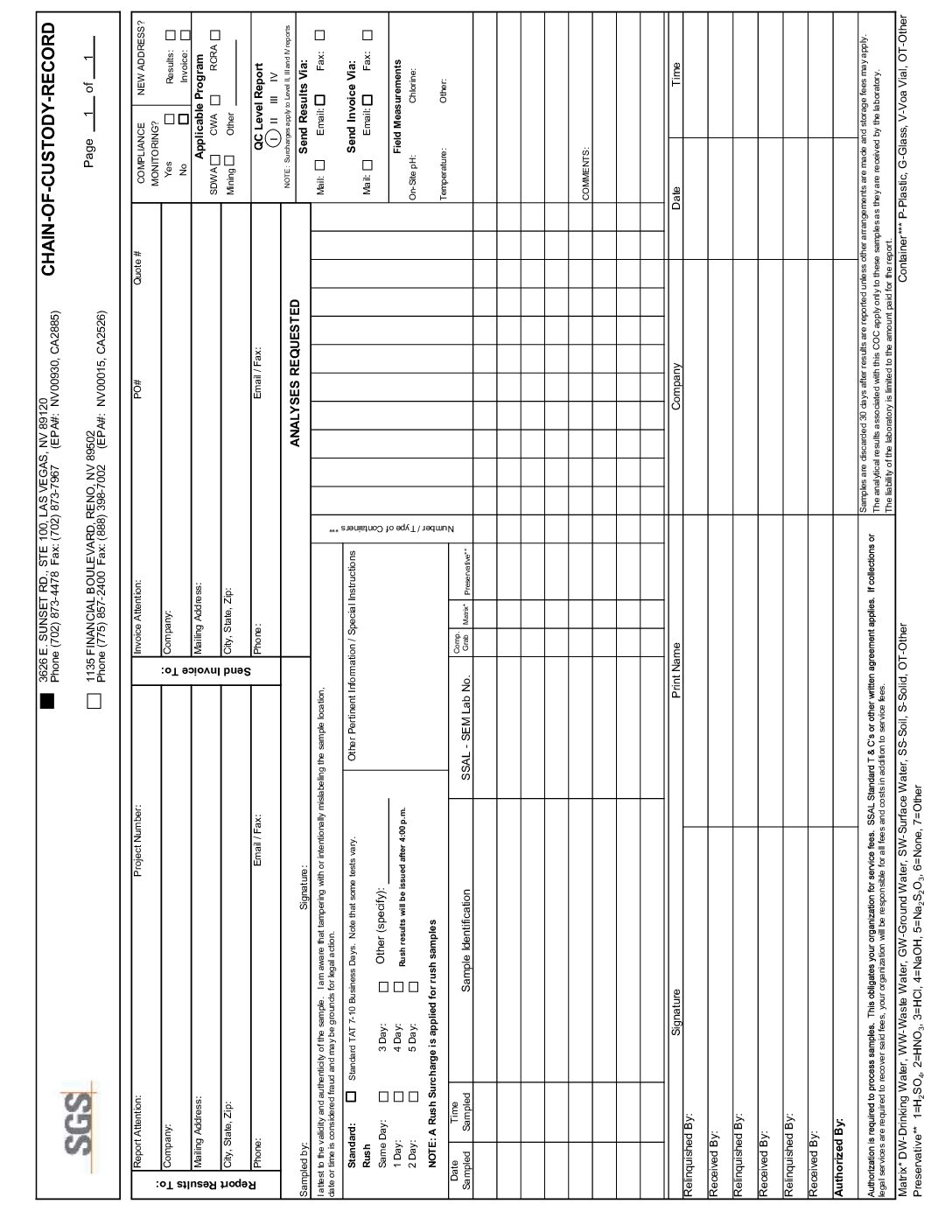

| Las Vegas, NV | SGS Las Vegas NVLAP | ISO/IEC 17025:2017, NVLAP | United States Department of Commerce National Institute of Standards & Technology | environmental-testing | not-applicable | las-vegas-nv | iso-iec-170252017 nvlap | united-states-department-of-commerce-national-institute-of-standards-technology | ||

| Las Vegas, NV | SGS Las Vegas AIHA | AIHA, ISO/IEC 17025:2017 | AIHA Laboratory Accreditation Program (AIHA LAP) | environmental-testing | not-applicable | las-vegas-nv | aiha iso-iec-170252017 | aiha-laboratory-accreditation-program-aiha-lap | ||

| Las Vegas, NV | SGS Las Vegas Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | environmental-testing | arizona | las-vegas-nv | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

| Las Vegas, NV | SGS Las Vegas Nevada | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing | nevada | las-vegas-nv | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Livonia, MI | SGS Livonia A2LA | DOD, ISO/IEC 17025:2017 | American Association for Laboratory Accreditation (A2LA) | materials-testing | not-applicable | livonia-mi | dod iso-iec-170252017 | american-association-for-laboratory-accreditation-a2la | ||

| Livonia, MI | SGS Livonia USDA | Foreign Soil | USDA | materials-testing | not-applicable | livonia-mi | foreign-soil | usda | ||

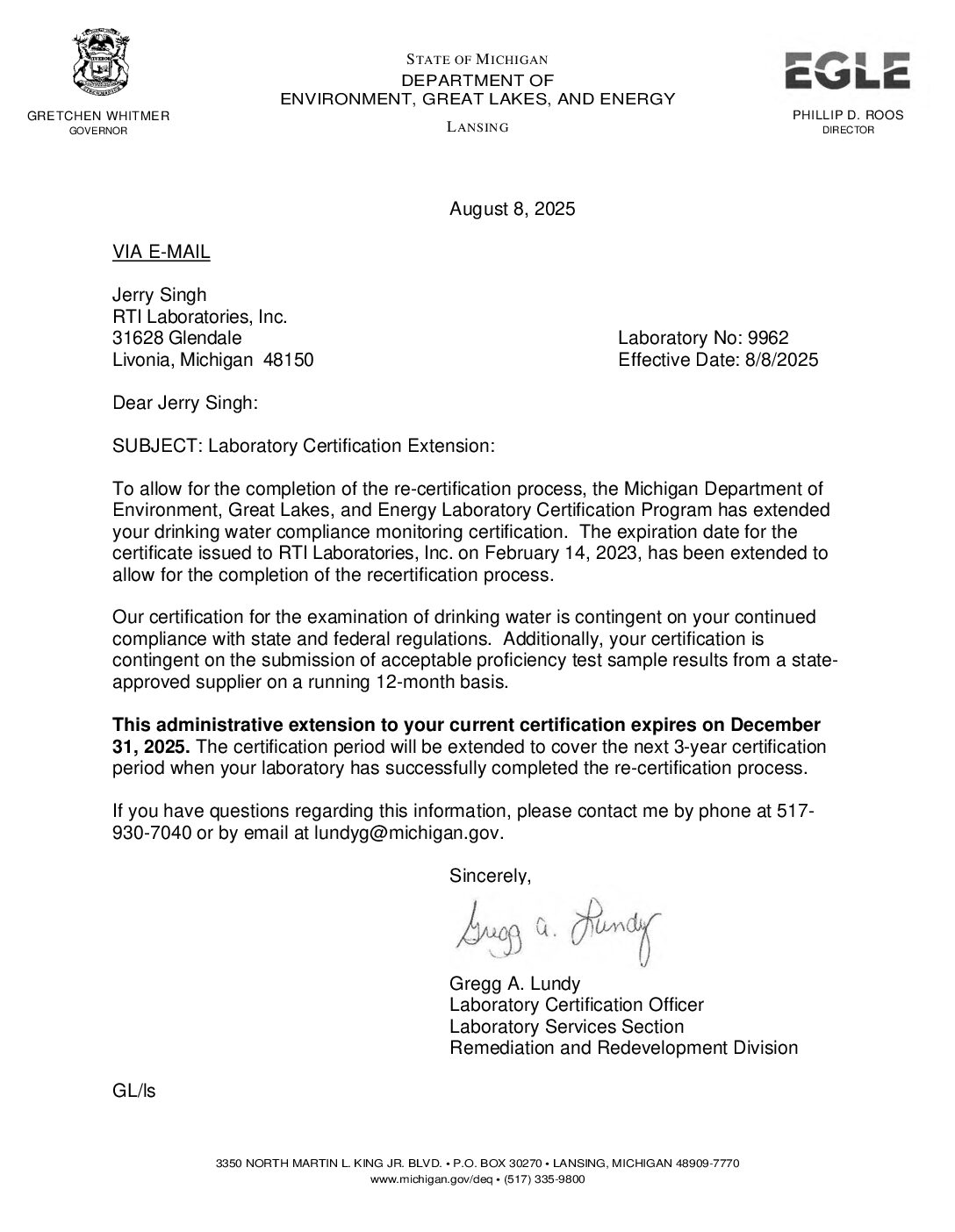

| Livonia, MI | SGS Livonia Michigan | Drinking Water | Michigan Department of Environment, Great Lakes, and Energy (MI EGLE) | materials-testing | michigan | livonia-mi | drinking-water | michigan-department-of-environment-great-lakes-and-energy-mi-egle | ||

| Livonia, MI | SGS Livonia Utah (NELAC) | TNI/NELAP | Utah Department of Health and Human Services (UT DHHS) | materials-testing | utah | livonia-mi | tni-nelap | utah-department-of-health-and-human-services-ut-dhhs | ||

| London, ON | SGS London Ontario | ISO/IEC 17025:2017 | Canadian Association for Laboratory Accreditation (CALA) | environmental-testing | canada ontario | london-on | iso-iec-170252017 | canadian-association-for-laboratory-accreditation-cala | ||

| Miami, FL | SGS Miami PJLA ISO IEC 17025 | ISO/IEC 17025:2017 | Perry Johnson Laboratory Accreditation, INC. | radiocarbon-isotopic-analysis | not-applicable | miami-fl | iso-iec-170252017 | perry-johnson-laboratory-accreditation-inc | ||

| Orlando, FL | SGS Orlando USDA | Foreign Soil | USDA | environmental-testing pfas-analysis | not-applicable | orlando-fl | foreign-soil | usda | ||

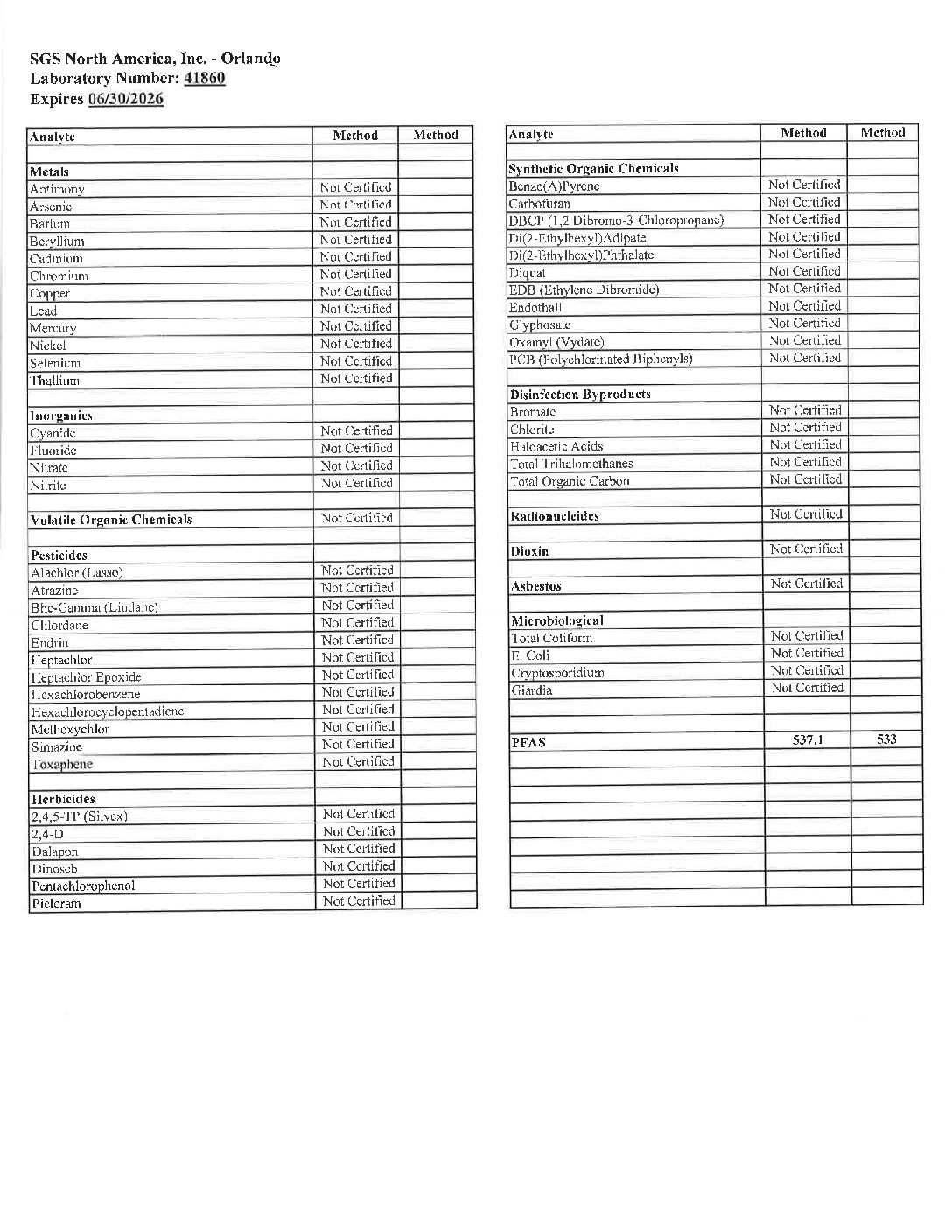

| Orlando, FL | SGS Orlando DoD Cert Parm | DOD, DOECAP, ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | environmental-testing pfas-analysis | not-applicable | orlando-fl | dod doecap iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

| Orlando, FL | SGS Orlando AL Parm | Drinking Water | Alabama Department of Environmental Management (ALDEM) | environmental-testing pfas-analysis | alabama | orlando-fl | drinking-water | alabama-department-of-environmental-management-aldem | ||

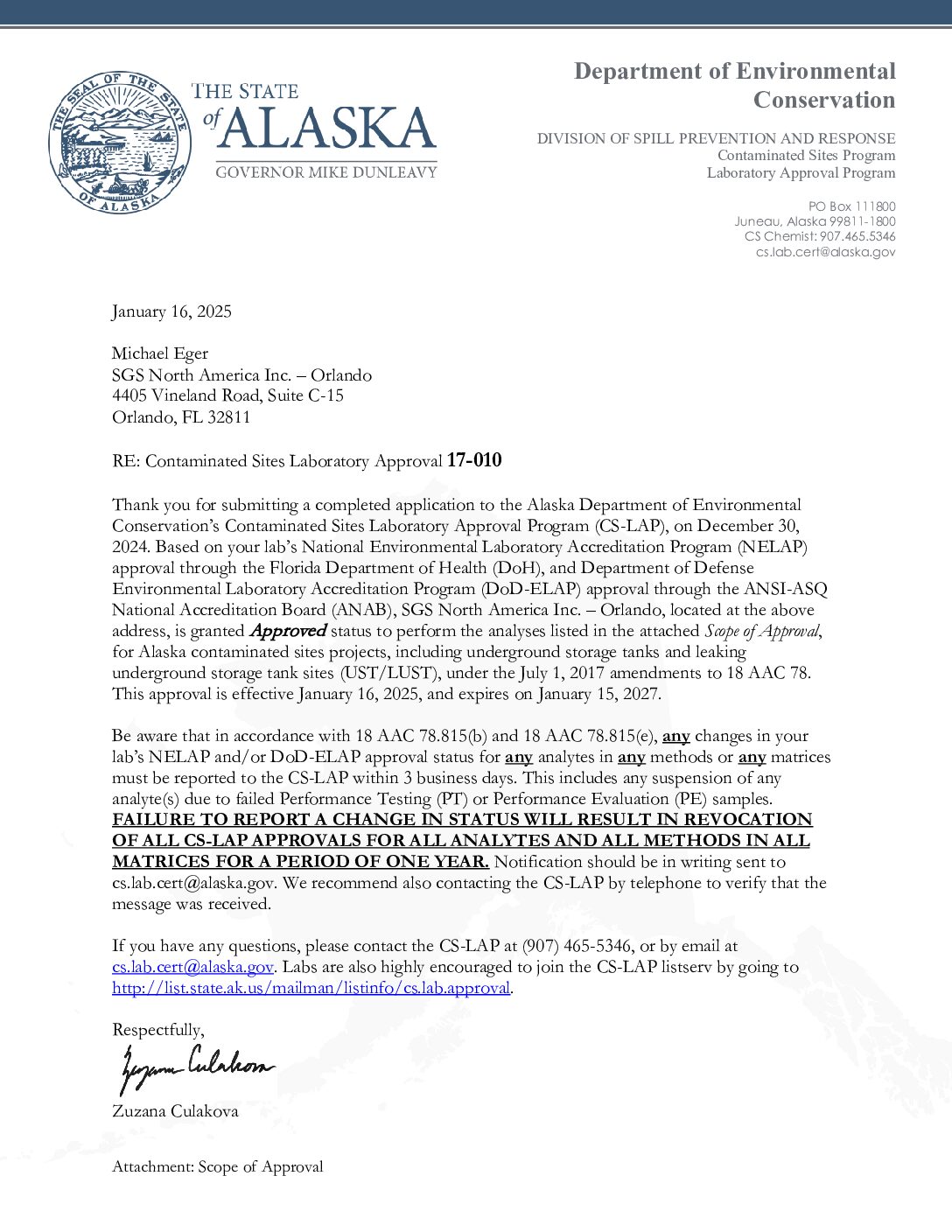

| Orlando, FL | SGS Orlando AK cert parm | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing pfas-analysis | alaska | orlando-fl | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Orlando, FL | SGS Orlando AK DW Parm | Drinking Water | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing pfas-analysis | alaska | orlando-fl | drinking-water | alaska-department-of-environmental-conservation-ak-dec | ||

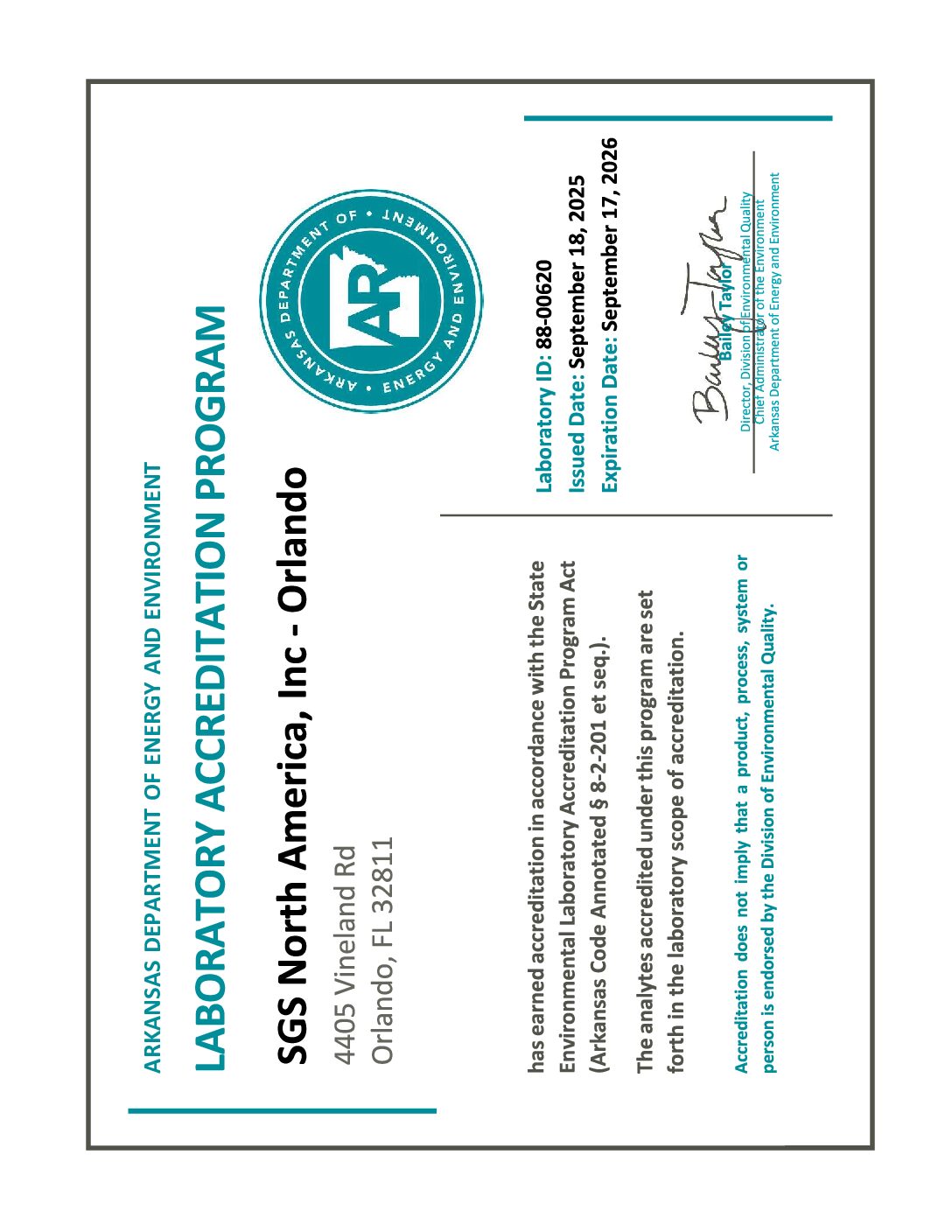

| Orlando, FL | SGS Orlando AR cert parm | Non-NELAP States | Arkansas Department of Environmental Quality (AR DEQ) | environmental-testing pfas-analysis | arkansas | orlando-fl | non-nelap-states | arkansas-department-of-environmental-quality-ar-deq | ||

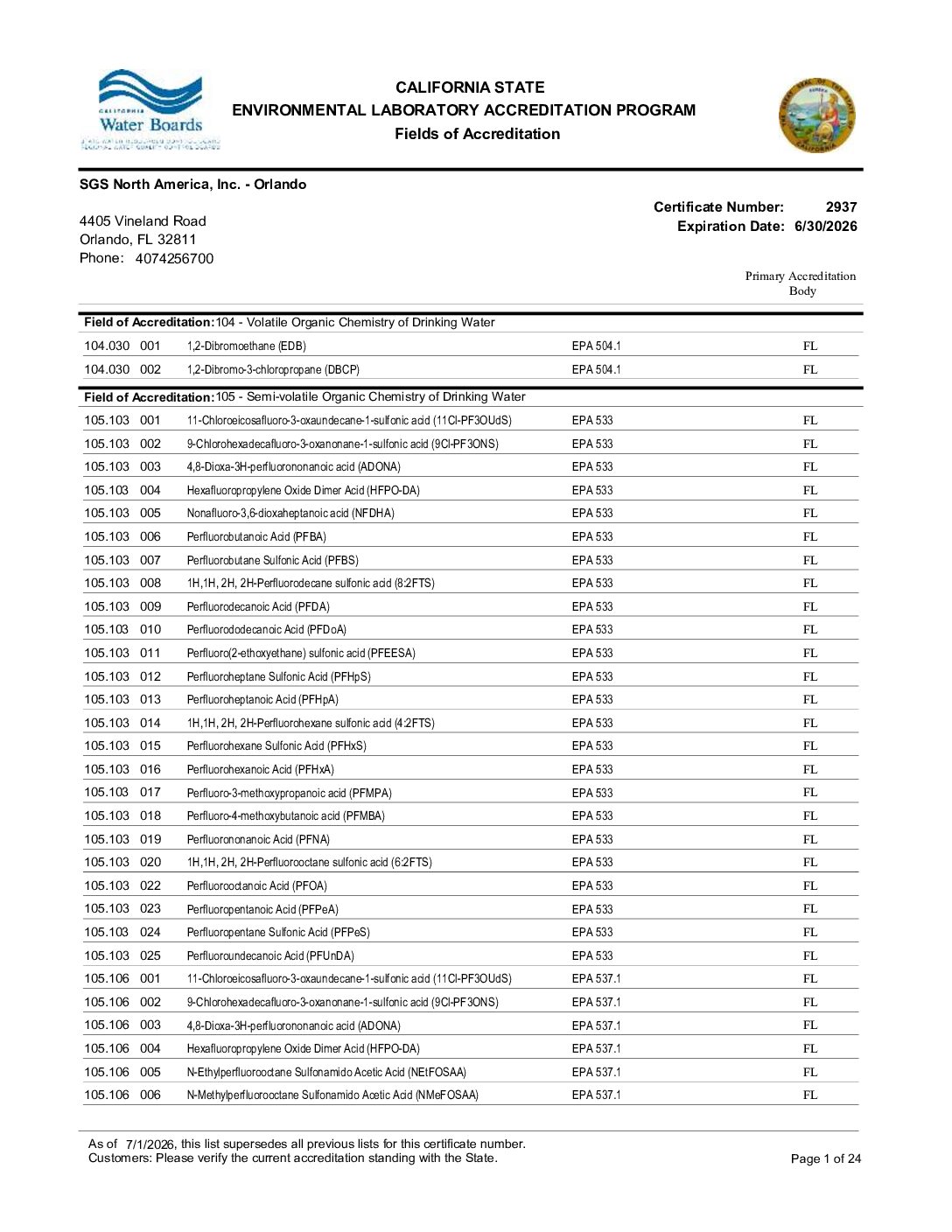

| Orlando, FL | SGS Orlando CA Parm | TNI - 2 (California) | California Waterboards | environmental-testing pfas-analysis | california | orlando-fl | tni-2-california | california-waterboards | ||

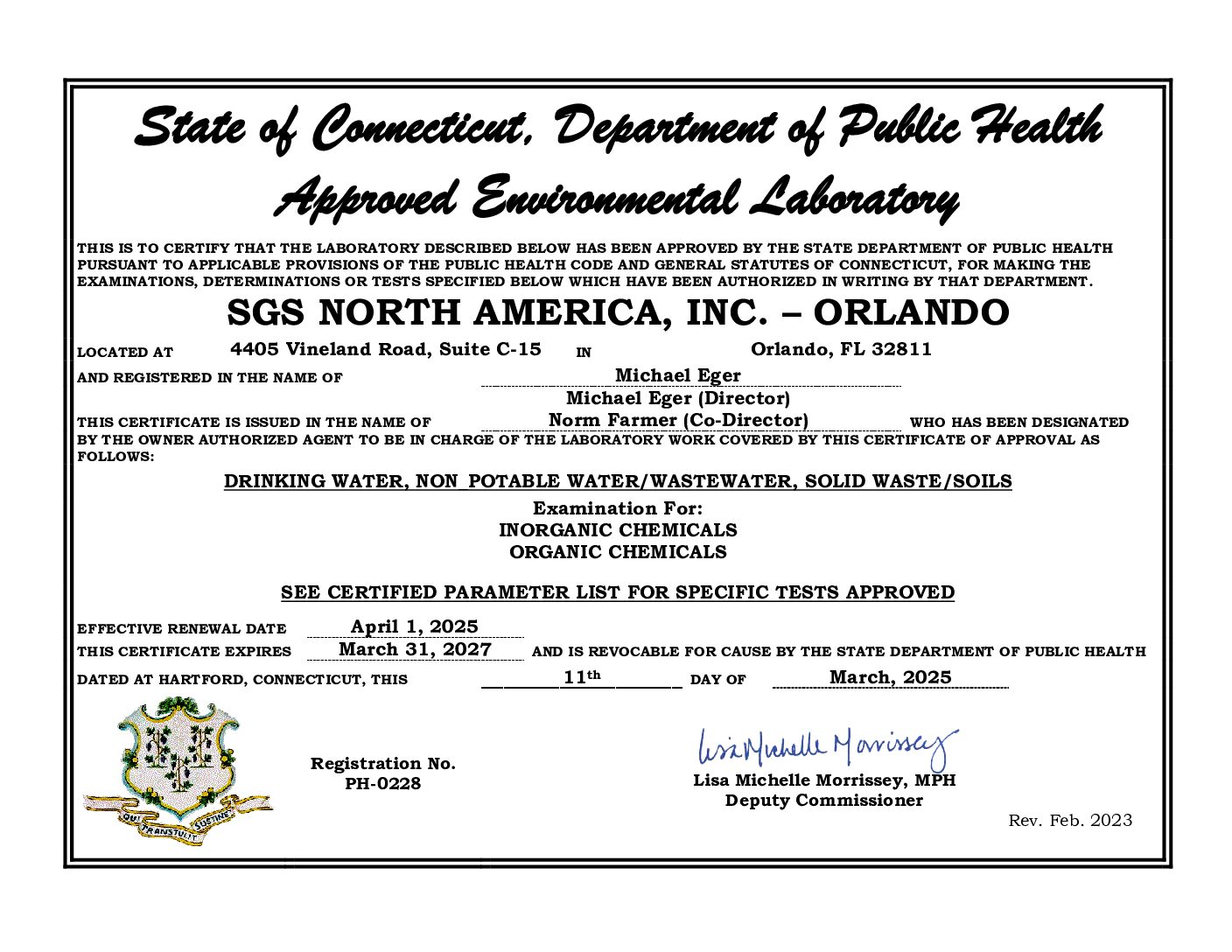

| Orlando, FL | SGS Orlando CT Cert Parm | Non-NELAP States | Connecticut Department of Public Health (CT DPH) | environmental-testing pfas-analysis | connecticut | orlando-fl | non-nelap-states | connecticut-department-of-public-health-ct-dph | ||

| Orlando, FL | SGS Orlando FL Parm | TNI/NELAP | Florida Department of Health (FL DOH) | environmental-testing pfas-analysis | florida | orlando-fl | tni-nelap | florida-department-of-health-fl-doh | ||

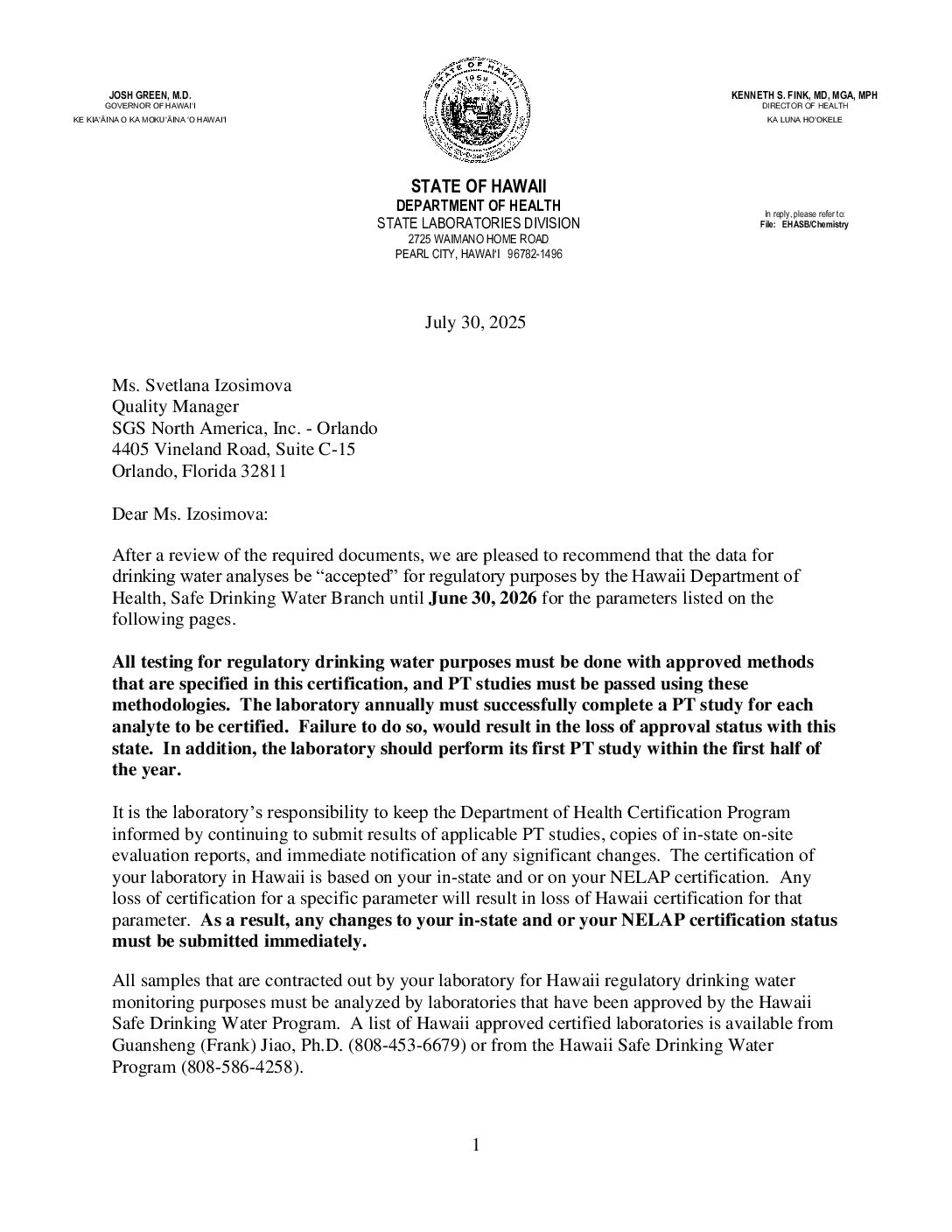

| Orlando, FL | SGS Orlando HI Cert Parm | Drinking Water | State of Hawaii Department of Health (HI DOH) | environmental-testing pfas-analysis | hawaii | orlando-fl | drinking-water | state-of-hawaii-department-of-health-hi-doh | ||

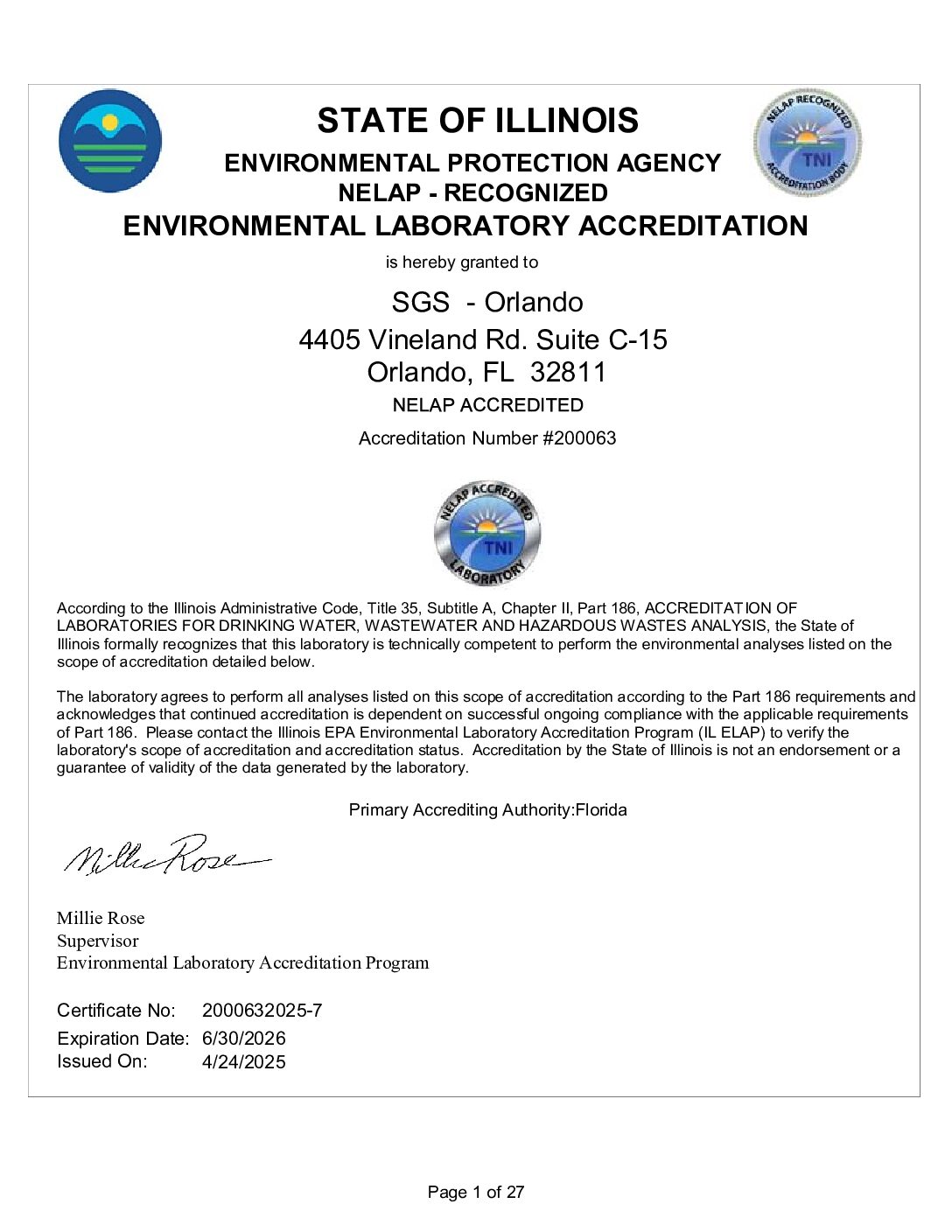

| Orlando, FL | SGS Orlando IL Cert Scope | TNI/NELAP | Illinois Environmental Protection Agency (IL EPA) | environmental-testing pfas-analysis | illinois | orlando-fl | tni-nelap | illinois-environmental-protection-agency-il-epa | ||

| Orlando, FL | SGS Orlando IA cert parm | Non-NELAP States | Iowa Department of Natural Resources (IA DNR) | environmental-testing pfas-analysis | iowa | orlando-fl | non-nelap-states | iowa-department-of-natural-resources-ia-dnr | ||

| Orlando, FL | SGS Orlando KS Cert Parm | TNI/NELAP | Kansas Department of Health and Environment (KS DHE) | environmental-testing pfas-analysis | kansas | orlando-fl | tni-nelap | kansas-department-of-health-and-environment-ks-dhe | ||

| Orlando, FL | SGS Orlando KY UST | Non-NELAP States | Kentucky Division of Waste Management Underground Storage Tank Branch (KY UST) | environmental-testing pfas-analysis | kentucky | orlando-fl | non-nelap-states | kentucky-division-of-waste-management-underground-storage-tank-branch-ky-ust | ||

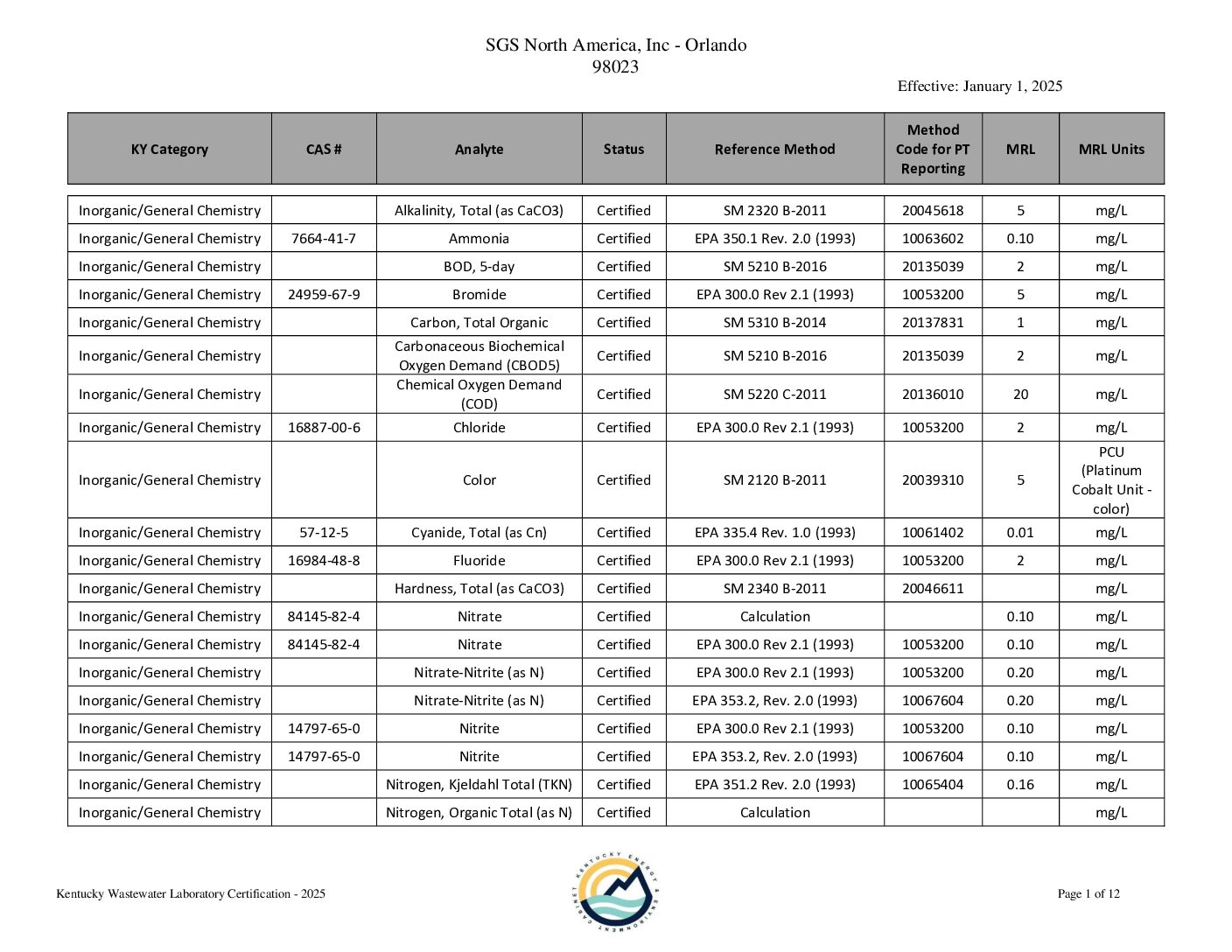

| Orlando, FL | SGS Orlando KY Parm | Non-NELAP States | Kentucky Energy and Environment Cabinet (KY EEC) | environmental-testing pfas-analysis | kentucky | orlando-fl | non-nelap-states | kentucky-energy-and-environment-cabinet-ky-eec | ||

| Orlando, FL | SGS Orlando LA Cert Parm | TNI/NELAP | Louisiana Department of Environmental Quality (LDEQ) | environmental-testing pfas-analysis | louisiana | orlando-fl | tni-nelap | louisiana-department-of-environmental-quality-ldeq | ||

| Orlando, FL | SGS Orlando LA DW cert+parm | Drinking Water | Louisiana Department of Health (LA DOH) | environmental-testing pfas-analysis | louisiana | orlando-fl | drinking-water | louisiana-department-of-health-la-doh | ||

| Orlando, FL | SGS Orlando ME Parm | Non-NELAP States | Maine Laboratory Accreditation Program (ME LAP) | environmental-testing pfas-analysis | maine | orlando-fl | non-nelap-states | maine-laboratory-accreditation-program-me-lap | ||

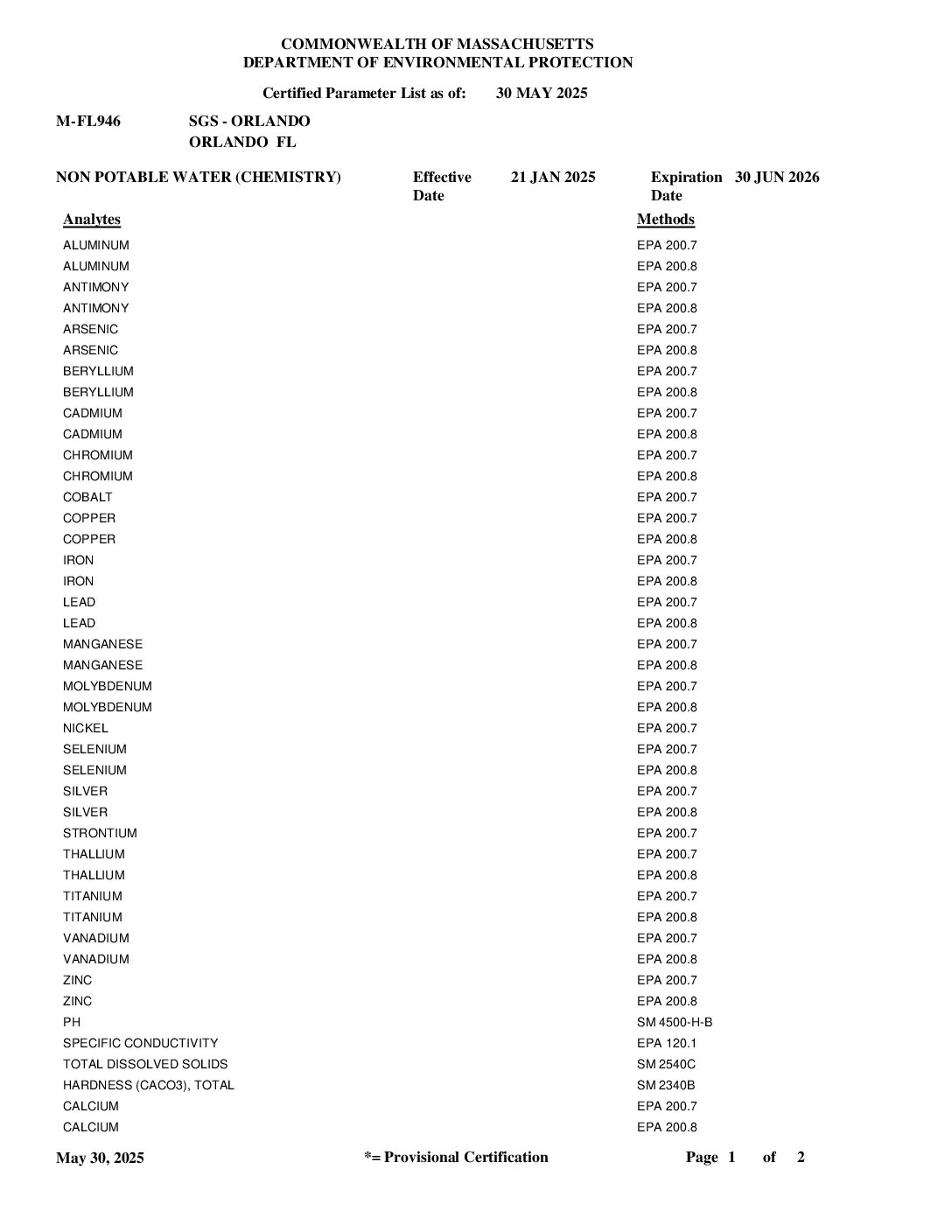

| Orlando, FL | SGS Orlando MA Parm | Non-NELAP States | Massachusetts Department of Environmental Protection (MADEP) | environmental-testing pfas-analysis | massachusetts | orlando-fl | non-nelap-states | massachusetts-department-of-environmental-protection-madep | ||

| Orlando, FL | SGS Orlando MI Cert Parm | Drinking Water | Michigan Department of Environment, Great Lakes, and Energy (MI EGLE) | environmental-testing pfas-analysis | michigan | orlando-fl | drinking-water | michigan-department-of-environment-great-lakes-and-energy-mi-egle | ||

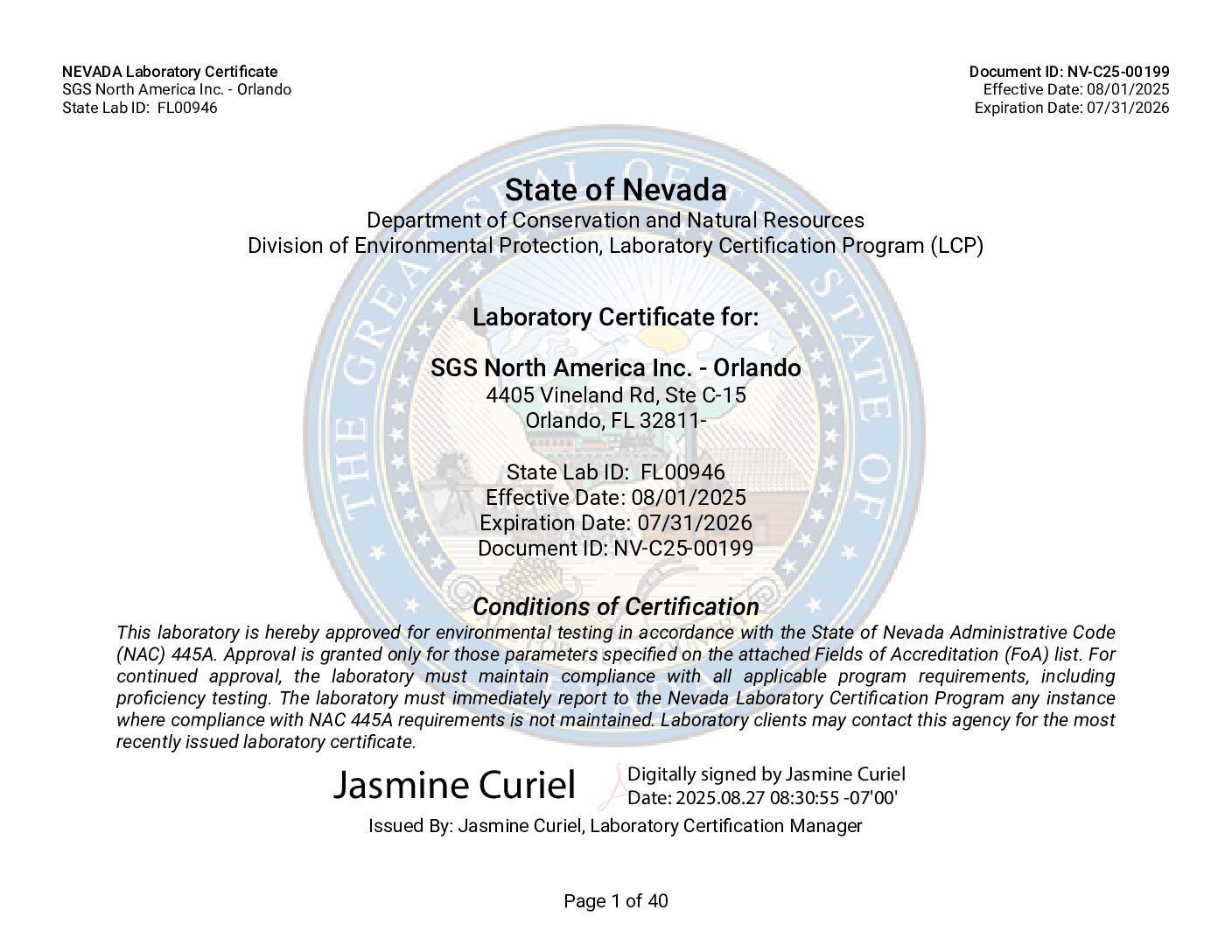

| Orlando, FL | SGS Orlando NV Cert and Scope | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing pfas-analysis | nevada | orlando-fl | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Orlando, FL | SGS Orlando NH Parm | TNI/NELAP | New Hampshire Environmental Laboratory Accreditation Program (NH ELAP) | environmental-testing pfas-analysis | new-hampshire | orlando-fl | tni-nelap | new-hampshire-environmental-laboratory-accreditation-program-nh-elap | ||

| Orlando, FL | SGS Orlando NJ Parm | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | environmental-testing pfas-analysis | new-jersey | orlando-fl | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

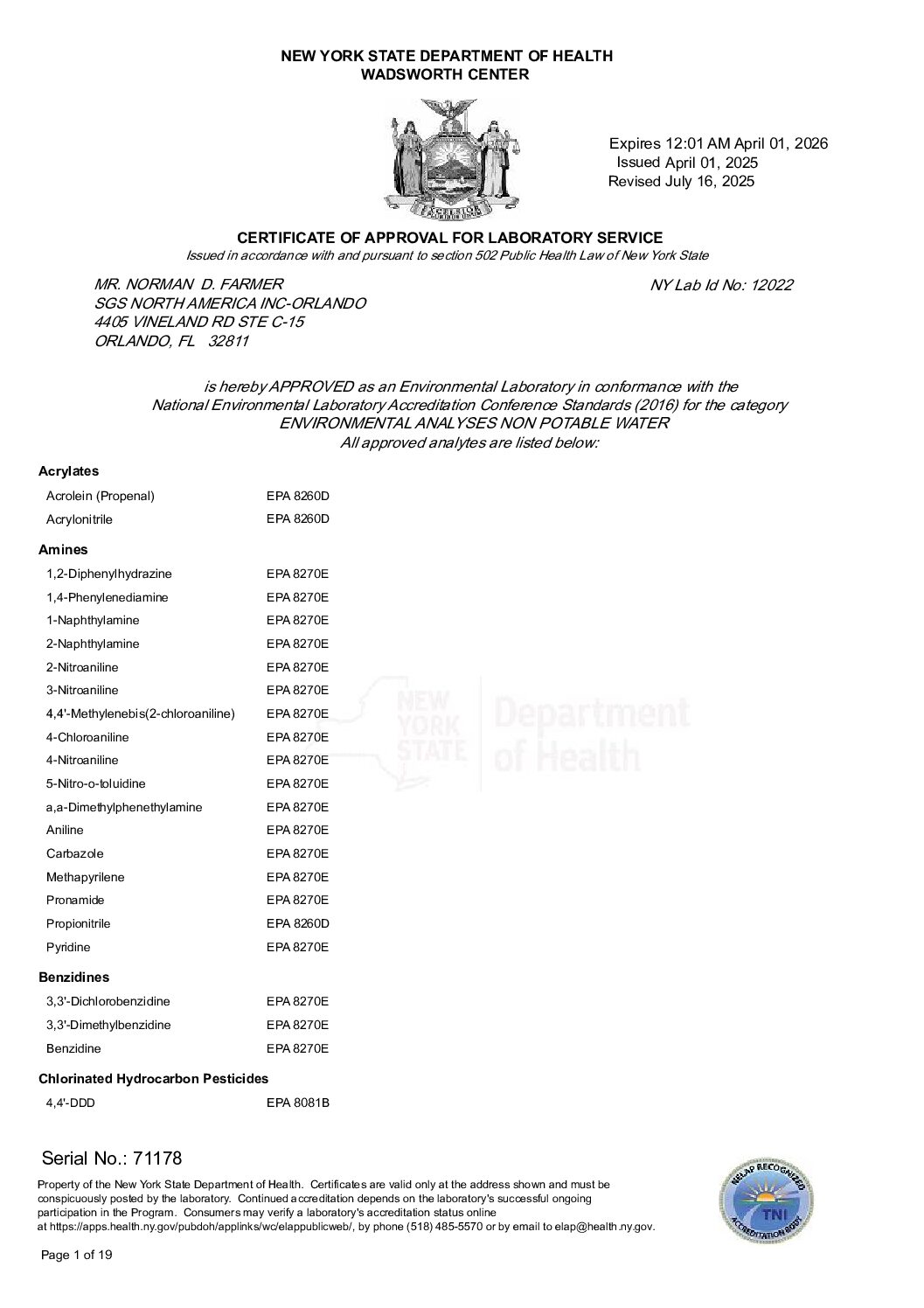

| Orlando, FL | SGS Orlando NY NPW | TNI/NELAP | New York State Department of Health (NY DOH) | environmental-testing pfas-analysis | new-york | orlando-fl | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Orlando, FL | SGS Orlando NC Parm | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | environmental-testing pfas-analysis | orlando-fl | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

| Orlando, FL | SGS Orlando ND Parm | Non-NELAP States | North Dakota State Department of Health (ND DOH) | environmental-testing pfas-analysis | north-dakota | orlando-fl | non-nelap-states | north-dakota-state-department-of-health-nd-doh | ||

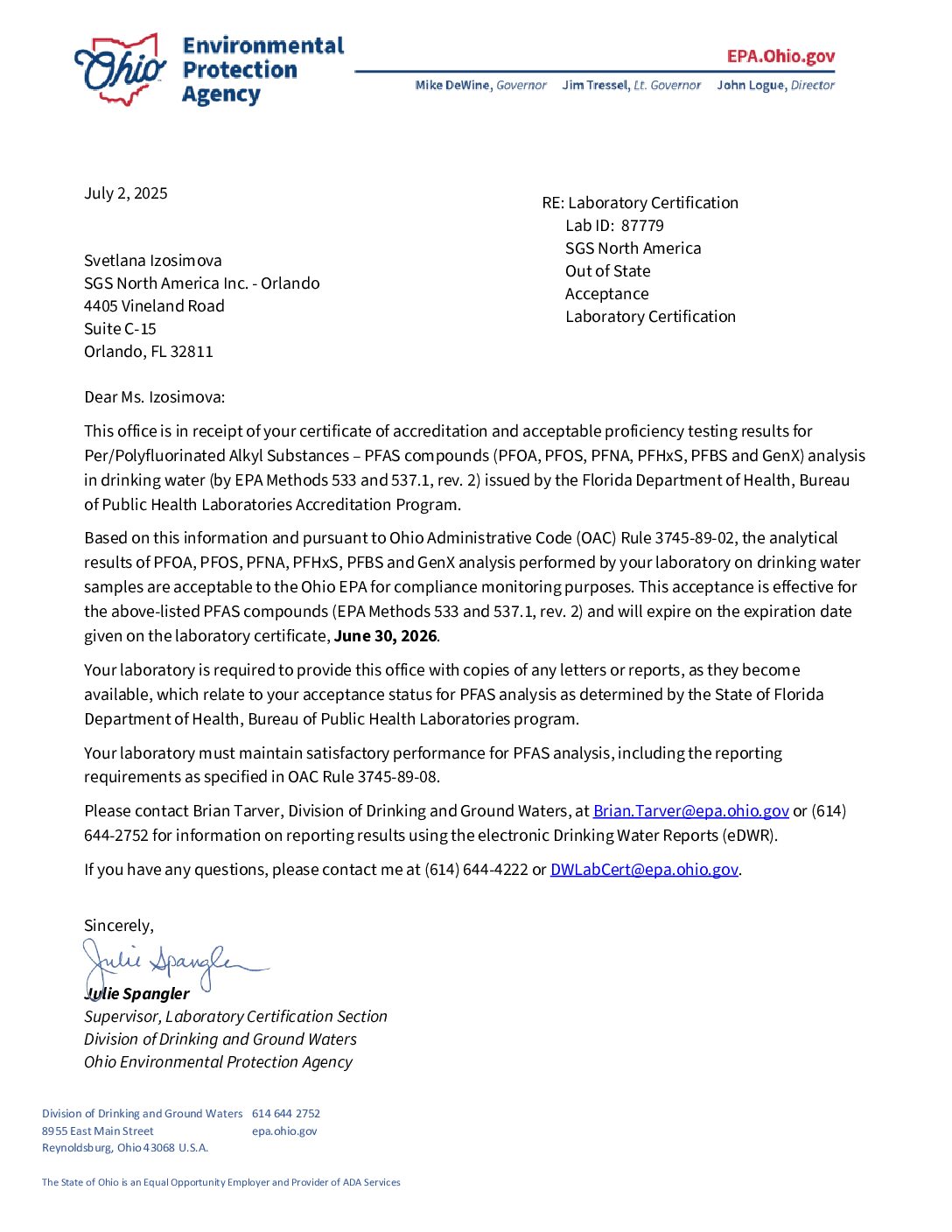

| Orlando, FL | SGS Orlando OH Letter | Drinking Water | Ohio Environmental Protection Agency (OH EPA) | environmental-testing pfas-analysis | ohio | orlando-fl | drinking-water | ohio-environmental-protection-agency-oh-epa | ||

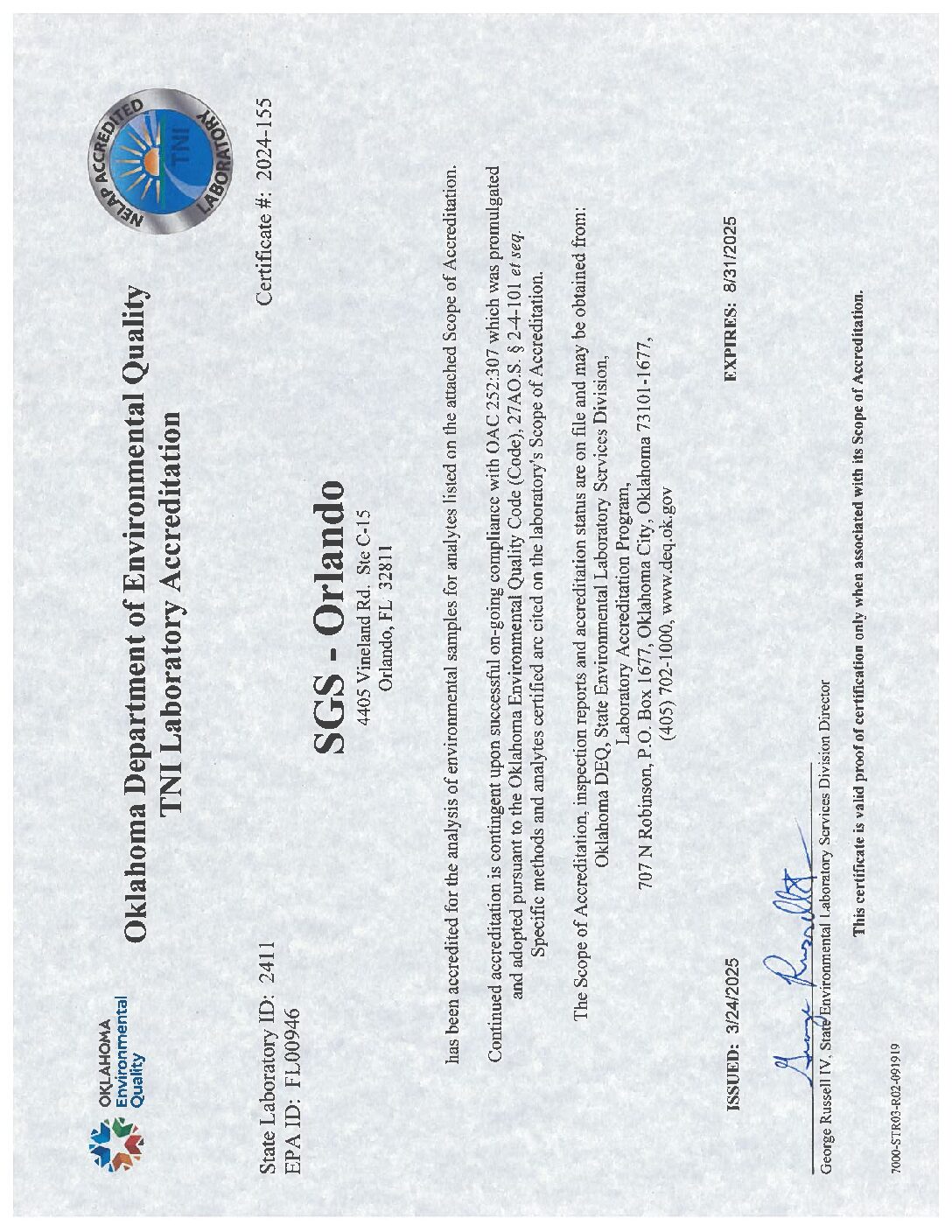

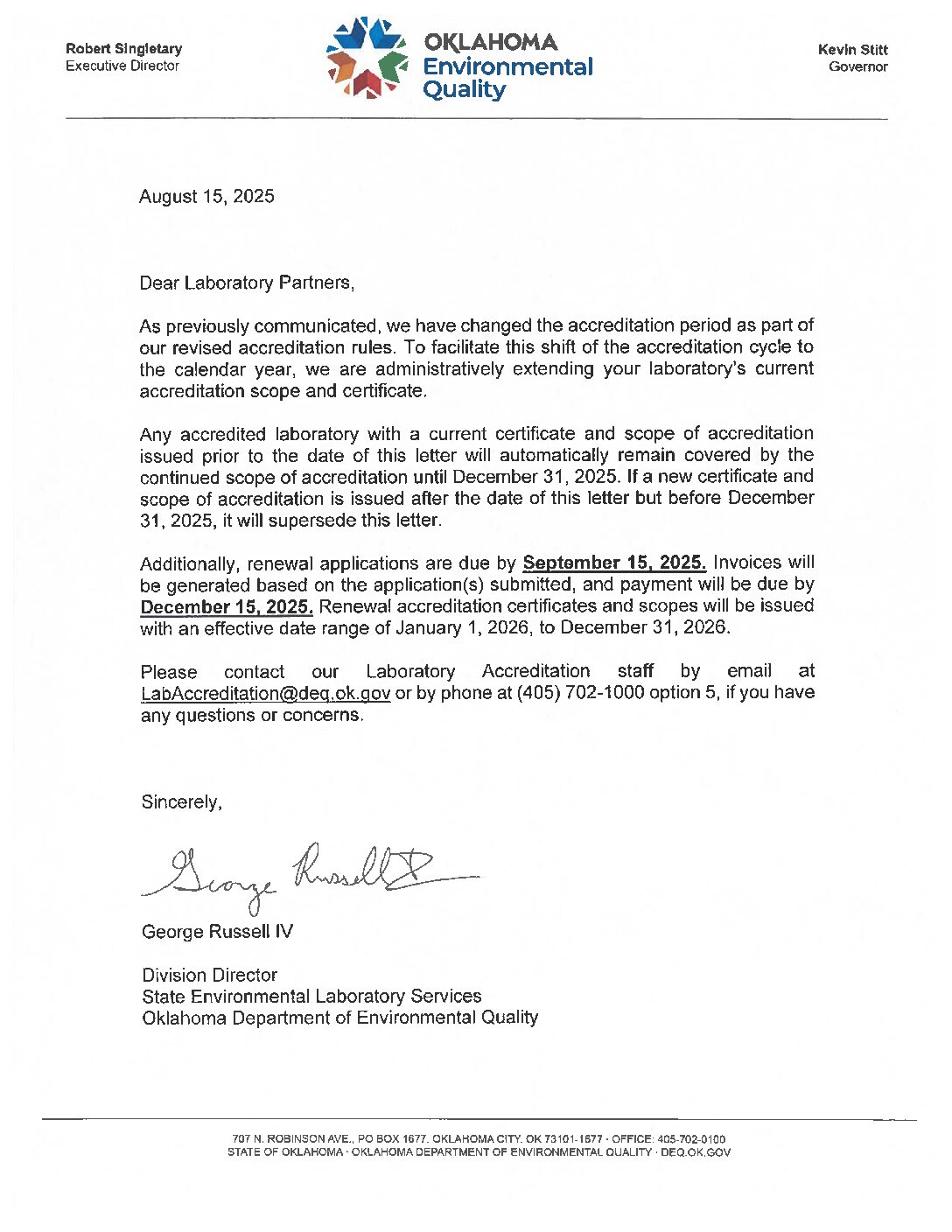

| Orlando, FL | SGS Orlando OK Cert Parm | TNI/NELAP | Oklahoma Department of Environmental Quality (OK DEQ) | environmental-testing pfas-analysis | oklahoma | orlando-fl | tni-nelap | oklahoma-department-of-environmental-quality-ok-deq | ||

| Orlando, FL | SGS Orlando OR Parm | TNI/NELAP | Oregon Laboratory Accreditation Program (ORELAP) | environmental-testing pfas-analysis | oregon | orlando-fl | tni-nelap | oregon-laboratory-accreditation-program-orelap | ||

| Orlando, FL | SGS Orlando PA scope | TNI/NELAP | Pennsylvania Department of Environmental Protection (PA DEP) | environmental-testing pfas-analysis | pennsylvania | orlando-fl | tni-nelap | pennsylvania-department-of-environmental-protection-pa-dep | ||

| Orlando, FL | SGS Orlando RI Cert | Non-NELAP States | Rhode Island Department of Health (RIDOH) | environmental-testing pfas-analysis | rhode-island | orlando-fl | non-nelap-states | rhode-island-department-of-health-ridoh | ||

| Orlando, FL | SGS Orlando SC Parm | Non-NELAP States | South Carolina Environmental Laboratory Certification Program (SC ELCP) | environmental-testing pfas-analysis | south-carolina | orlando-fl | non-nelap-states | south-carolina-environmental-laboratory-certification-program-sc-elcp | ||

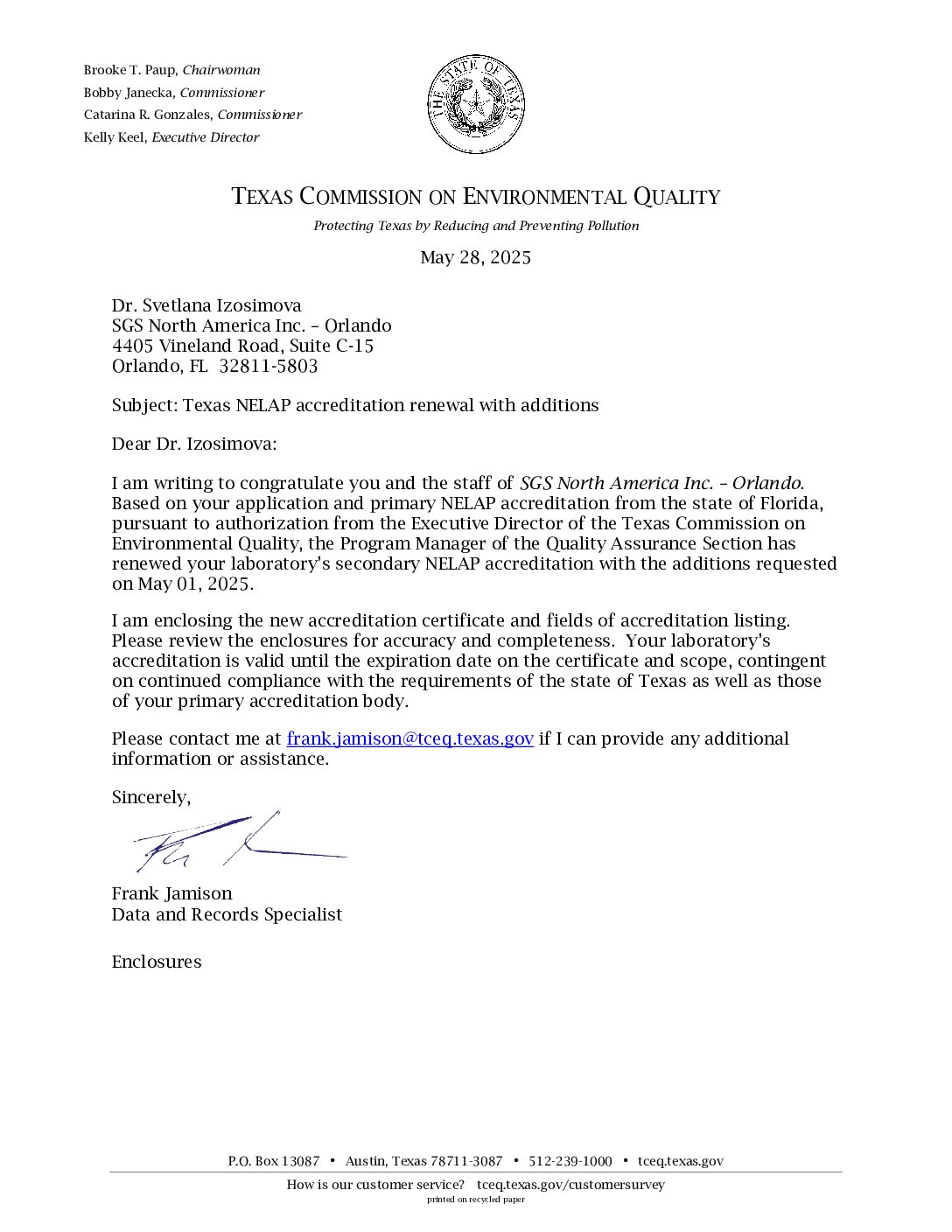

| Orlando, FL | SGS Orlando TX cert parm | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | environmental-testing pfas-analysis | texas | orlando-fl | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Orlando, FL | SGS Orlando UT scope | TNI/NELAP | Utah Department of Health and Human Services (UT DHHS) | environmental-testing pfas-analysis | utah | orlando-fl | tni-nelap | utah-department-of-health-and-human-services-ut-dhhs | ||

| Orlando, FL | SGS Orlando VT Cert Parm | Non-NELAP States | State of Vermont, Department of Health (VT DOH) | environmental-testing pfas-analysis | vermont | orlando-fl | non-nelap-states | state-of-vermont-department-of-health-vt-doh | ||

| Orlando, FL | SGS Orlando VA Cert Scope | TNI/NELAP | Virginia Department of General Services (VA DGS) | environmental-testing pfas-analysis | virginia | orlando-fl | tni-nelap | virginia-department-of-general-services-va-dgs | ||

| Orlando, FL | SGS Orlando WA Cert-parm | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | environmental-testing pfas-analysis | washington | orlando-fl | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

| Orlando, FL | SGS Orlando WV scope minus 1633 | Non-NELAP States | West Virginia Department of Environmental Protection (WV DEP) | environmental-testing pfas-analysis | west-virginia | orlando-fl | non-nelap-states | west-virginia-department-of-environmental-protection-wv-dep | ||

| Orlando, FL | SGS Orlando WI Scope | Non-NELAP States | State of Wisconsin Department of Natural Resources (WI DNR) | environmental-testing pfas-analysis | wisconsin | orlando-fl | non-nelap-states | state-of-wisconsin-department-of-natural-resources-wi-dnr | ||

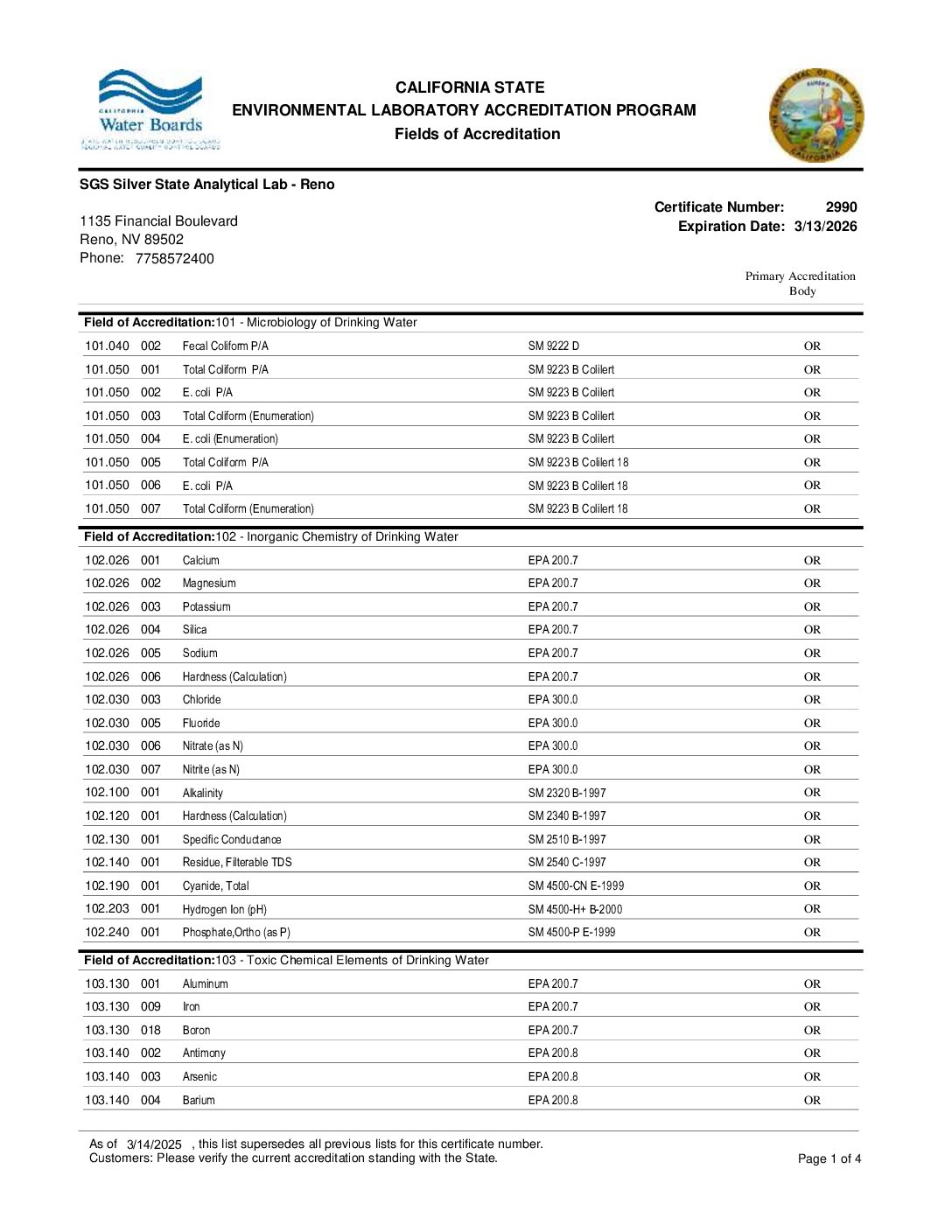

| Reno, NV | SGS Reno CA | TNI - 2 (California) | California Waterboards | environmental-testing mining | california | reno-nv | tni-2-california | california-waterboards | ||

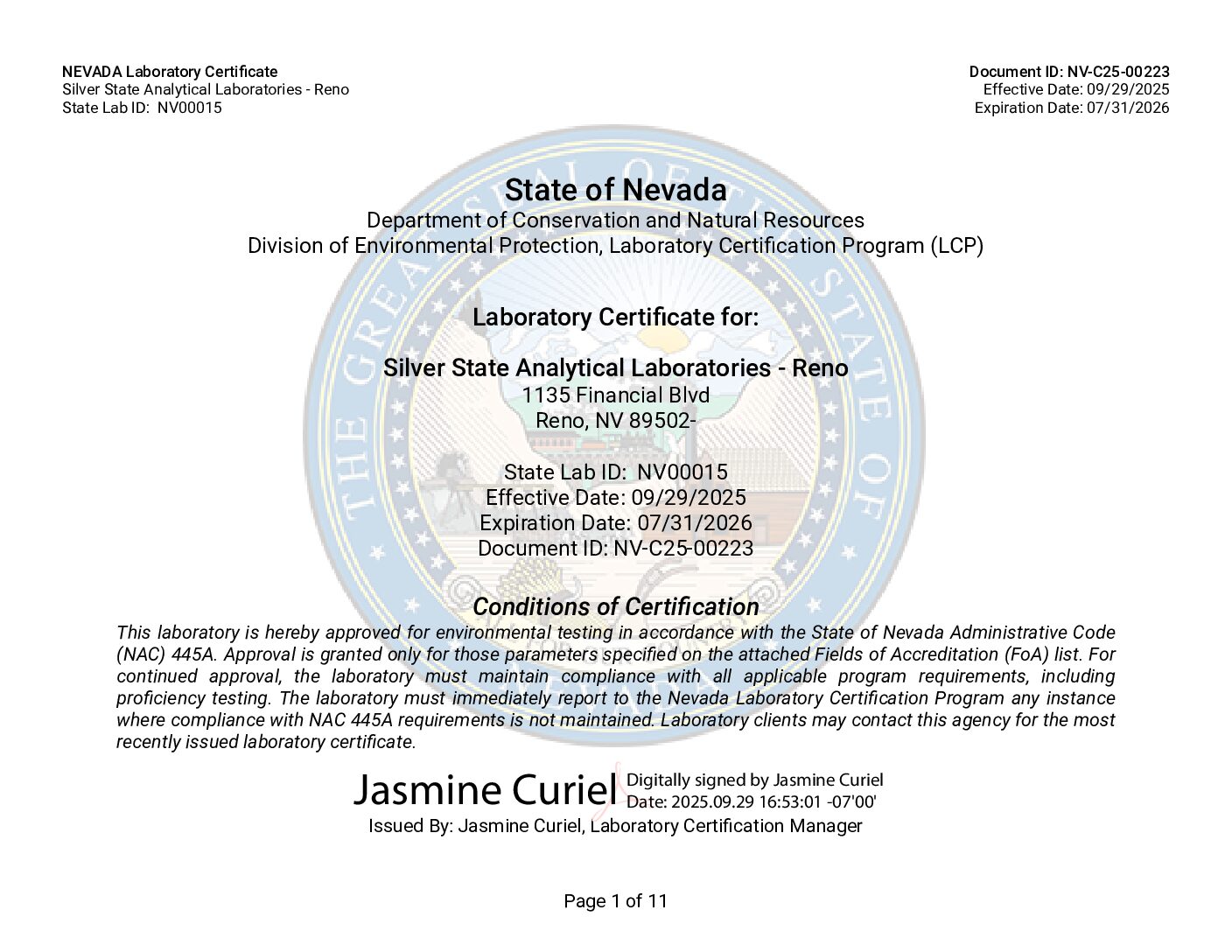

| Reno, NV | SGS Reno NV | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing mining | nevada | reno-nv | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

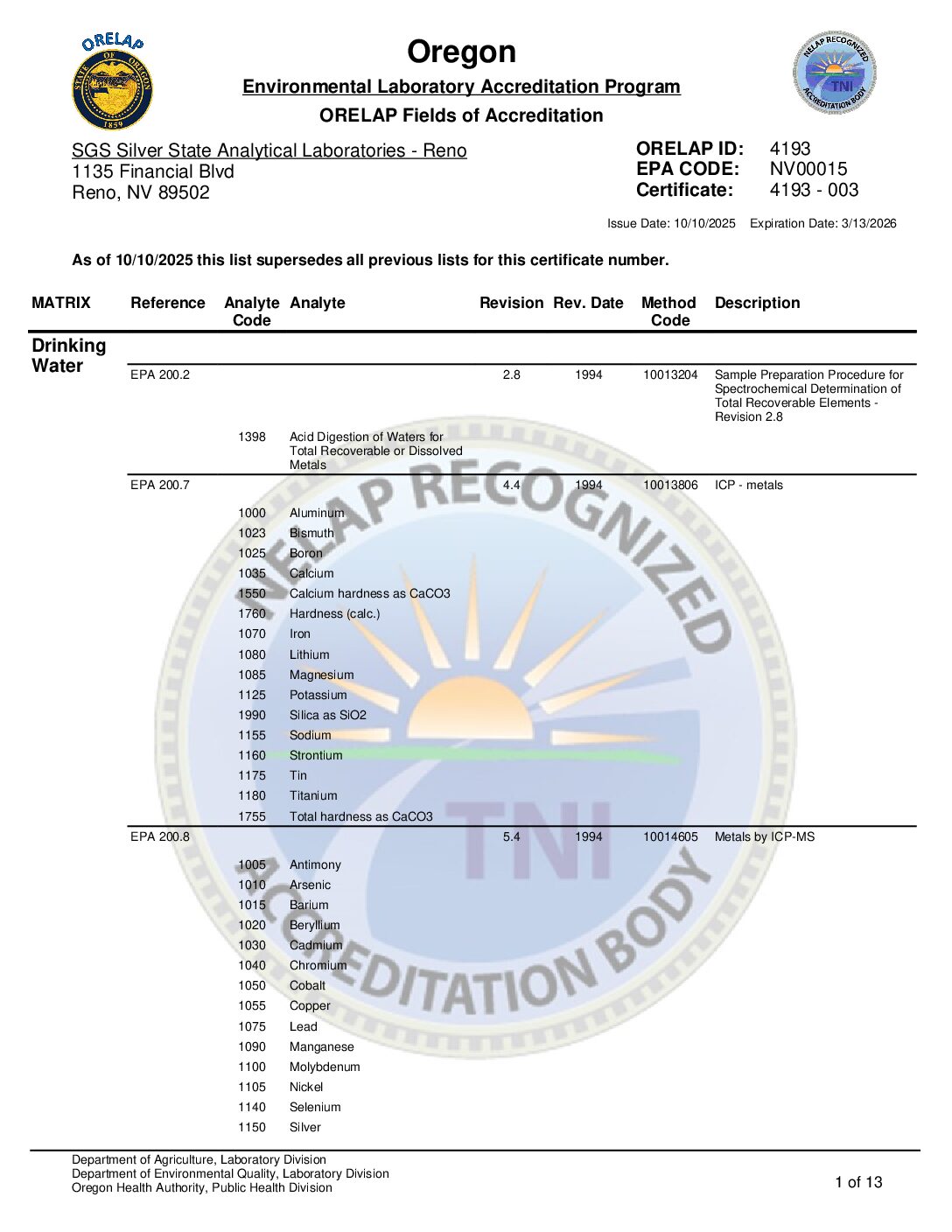

| Reno, NV | SGS Reno OR | TNI/NELAP | Oregon Laboratory Accreditation Program (ORELAP) | environmental-testing mining | oregon | reno-nv | tni-nelap | oregon-laboratory-accreditation-program-orelap | ||

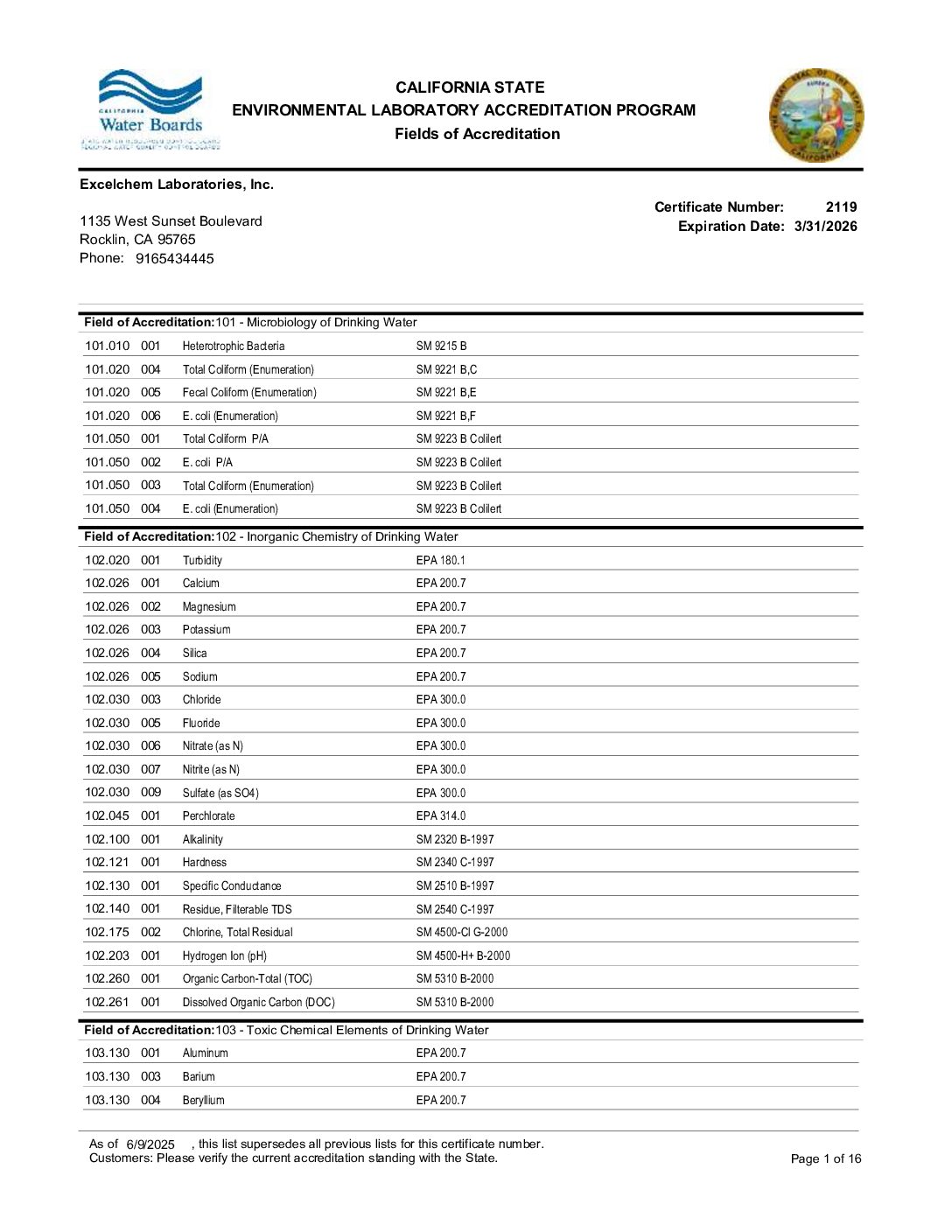

| Rocklin, CA | SGS Rocklin CA | TNI - 2 (California) | California Waterboards | environmental-testing | california | rocklin-ca | tni-2-california | california-waterboards | ||

| Rocklin, CA | SGS Rocklin NV | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing | nevada | rocklin-ca | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Scarborough, ME | SGS Scarborough DoD | DOD, ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | environmental-testing pfas-analysis | not-applicable | scarborough-me | dod iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

| Scarborough, ME | SGS Scarborough AOAC | AOAC, ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | environmental-testing pfas-analysis | not-applicable | scarborough-me | aoac iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

| Scarborough, ME | SGS Scarborough USDA | Foreign Soil | USDA | environmental-testing pfas-analysis | not-applicable | scarborough-me | foreign-soil | usda | ||

| Scarborough, ME | SGS Scarborough AK | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing pfas-analysis | alaska | scarborough-me | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Scarborough, ME | SGS Scarborough CT | Non-NELAP States | Connecticut Department of Public Health (CT DPH) | environmental-testing pfas-analysis | connecticut | scarborough-me | non-nelap-states | connecticut-department-of-public-health-ct-dph | ||

| Scarborough, ME | SGS Scarborough FL | TNI/NELAP | Florida Department of Health (FL DOH) | environmental-testing pfas-analysis | florida | scarborough-me | tni-nelap | florida-department-of-health-fl-doh | ||

| Scarborough, ME | SGS Scarborough ME | Non-NELAP States | Maine Laboratory Accreditation Program (ME LAP) | environmental-testing pfas-analysis | maine | scarborough-me | non-nelap-states | maine-laboratory-accreditation-program-me-lap | ||

| Scarborough, ME | SGS Scarborough MD | Non-NELAP States | Maryland Department of the Environment Water Supply Program (MD DOE) | environmental-testing pfas-analysis | maryland | scarborough-me | non-nelap-states | maryland-department-of-the-environment-water-supply-program-md-doe | ||

| Scarborough, ME | SGS Scarborough MA | Non-NELAP States | Massachusetts Department of Environmental Protection (MADEP) | environmental-testing pfas-analysis | massachusetts | scarborough-me | non-nelap-states | massachusetts-department-of-environmental-protection-madep | ||

| Scarborough, ME | SGS Scarborough NH | TNI/NELAP | New Hampshire Environmental Laboratory Accreditation Program (NH ELAP) | environmental-testing pfas-analysis | new-hampshire | scarborough-me | tni-nelap | new-hampshire-environmental-laboratory-accreditation-program-nh-elap | ||

| Scarborough, ME | SGS Scarborough NJ | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | environmental-testing pfas-analysis | new-jersey | scarborough-me | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

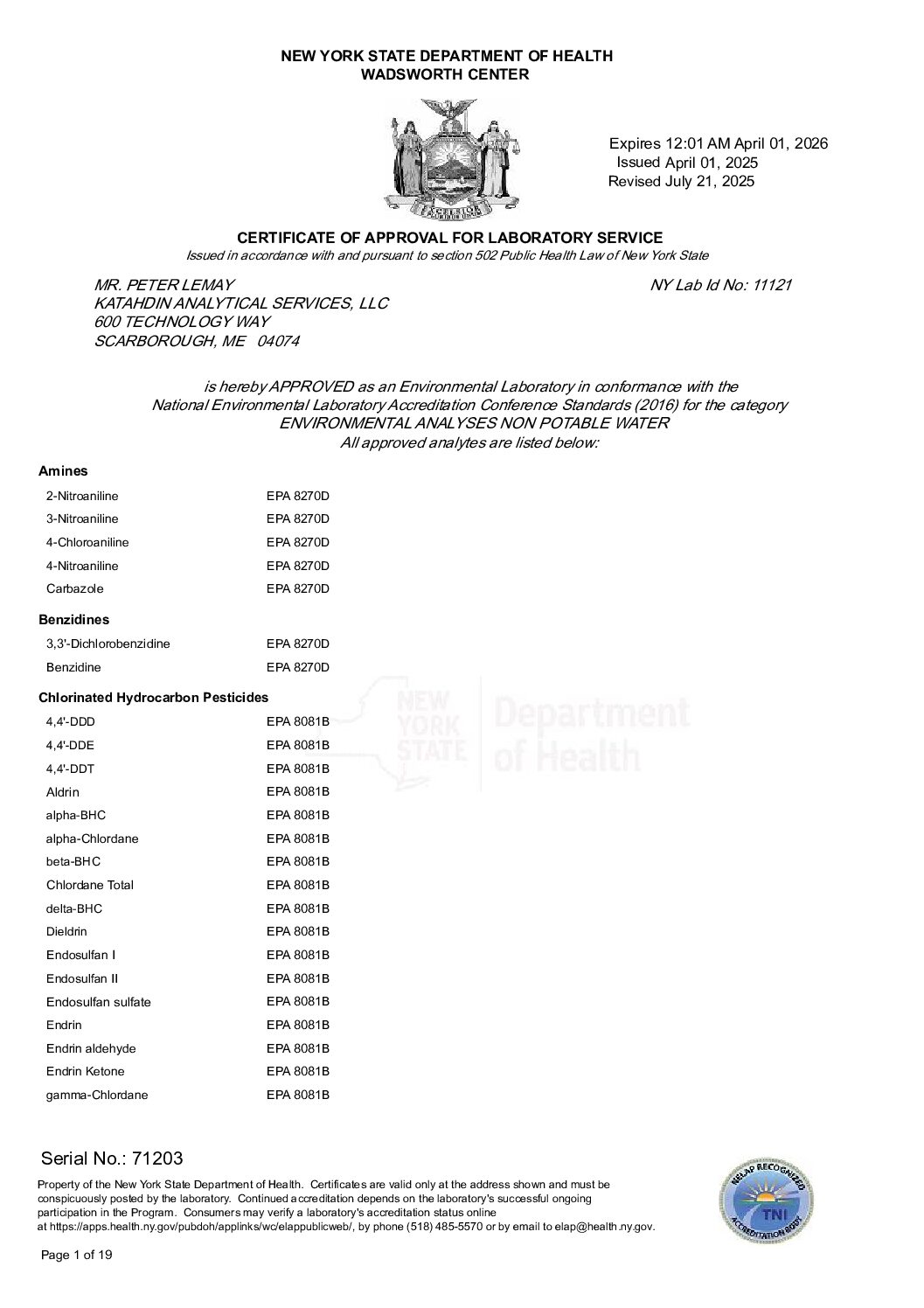

| Scarborough, ME | SGS Scarborough NY | TNI/NELAP | New York State Department of Health (NY DOH) | environmental-testing pfas-analysis | new-york | scarborough-me | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Scarborough, ME | SGS Scarborough NC | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | environmental-testing pfas-analysis | scarborough-me | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

| Scarborough, ME | SGS Scarborough RI | Non-NELAP States | Rhode Island Department of Health (RIDOH) | environmental-testing pfas-analysis | rhode-island | scarborough-me | non-nelap-states | rhode-island-department-of-health-ridoh | ||

| Scarborough, ME | SGS Scarborough SC | Non-NELAP States | South Carolina Environmental Laboratory Certification Program (SC ELCP) | environmental-testing pfas-analysis | south-carolina | scarborough-me | non-nelap-states | south-carolina-environmental-laboratory-certification-program-sc-elcp | ||

| Scarborough, ME | SGS Scarborough TX | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | environmental-testing pfas-analysis | texas | scarborough-me | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Scarborough, ME | SGS Scarborough VA | TNI/NELAP | Virginia Department of General Services (VA DGS) | environmental-testing pfas-analysis | virginia | scarborough-me | tni-nelap | virginia-department-of-general-services-va-dgs | ||

| Scarborough, ME | SGS Scarborough WA | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | environmental-testing pfas-analysis | washington | scarborough-me | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

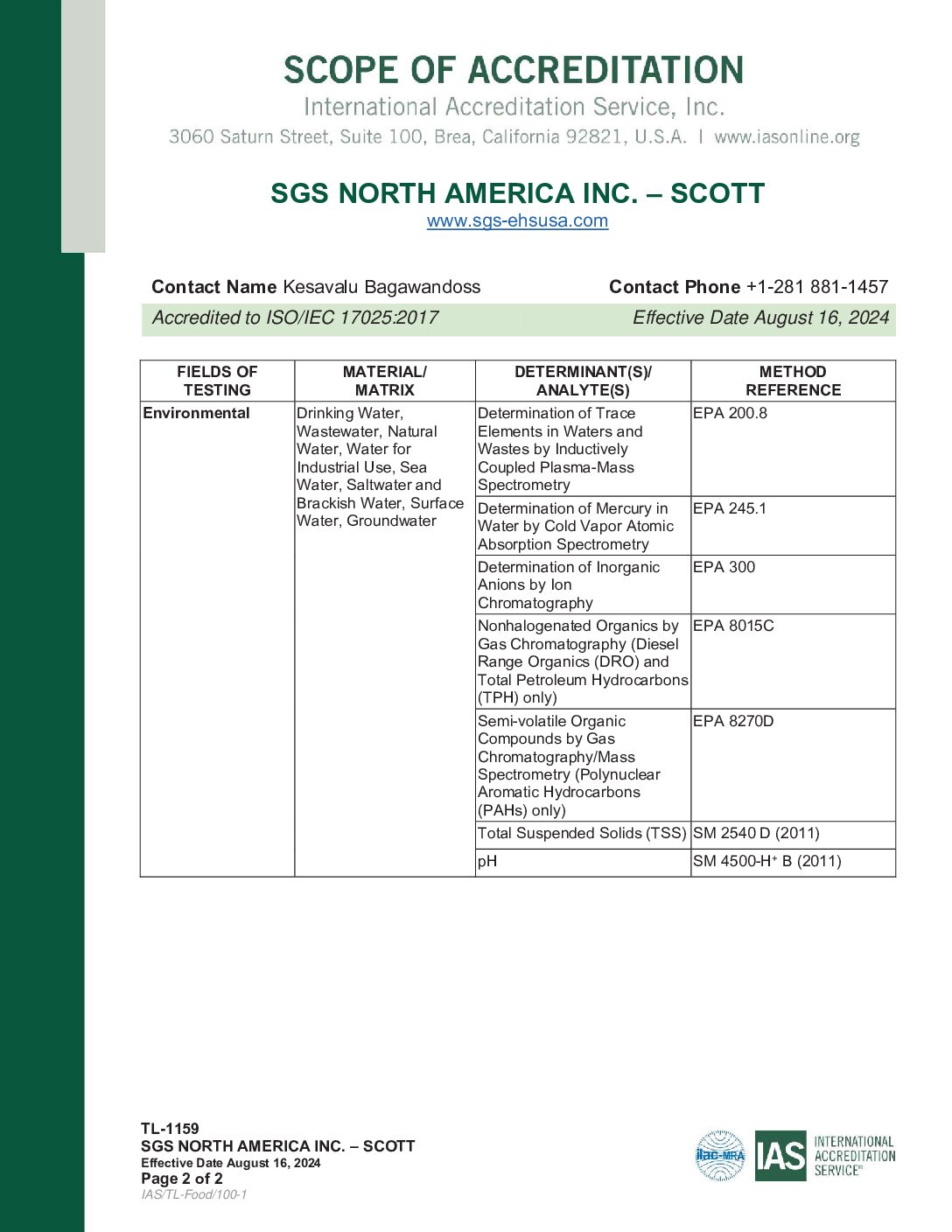

| Scott, LA | SGS Scott ISO | ISO/IEC 17025:2017 | International Accreditation Service (IAS) | environmental-forensics environmental-testing | not-applicable | scott-la | iso-iec-170252017 | international-accreditation-service-ias | ||

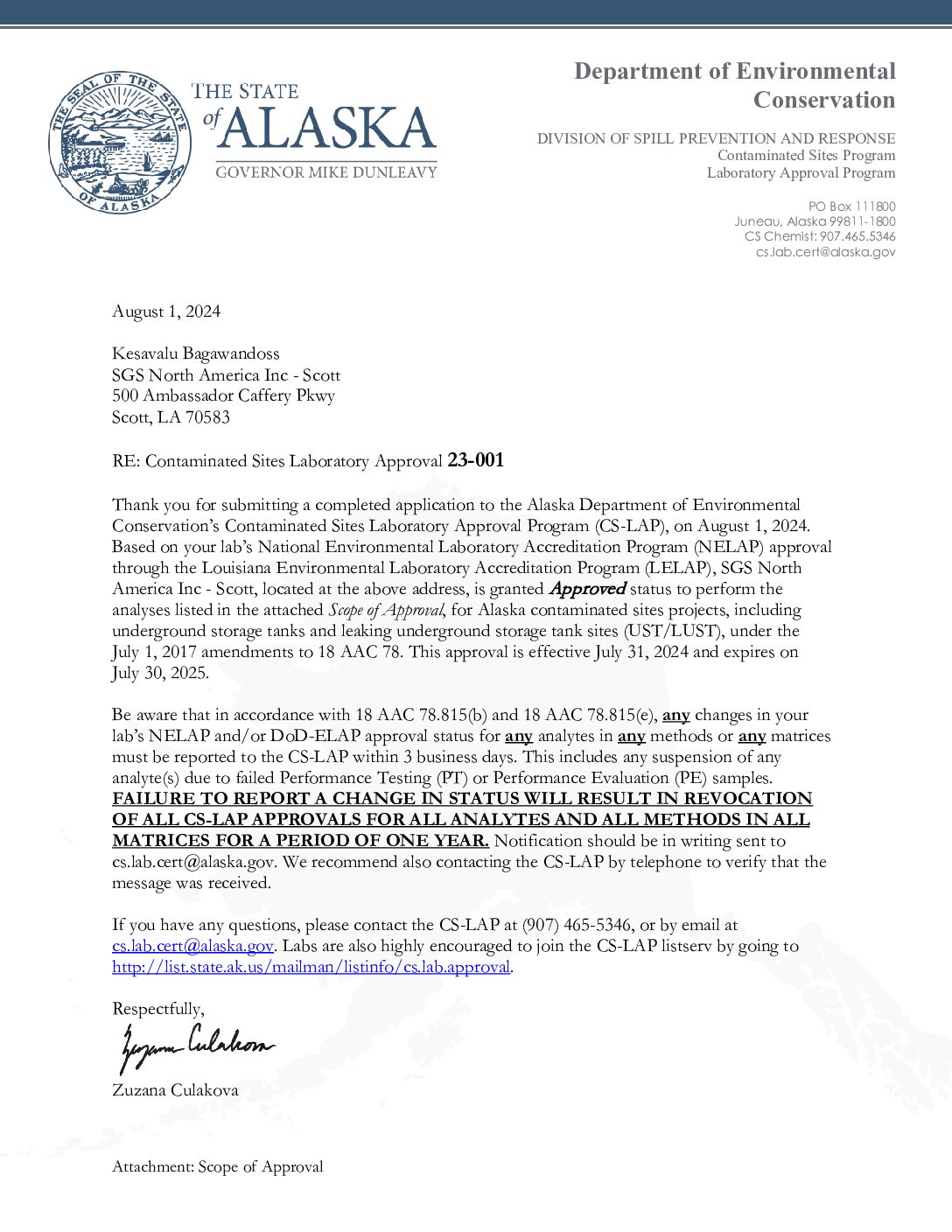

| Scott, LA | SGS Scott Alaska | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | environmental-forensics environmental-testing | alaska | scott-la | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Scott, LA | SGS Scott Arizona | Non-NELAP States | Arizona Department of Health Services (AZ DHS) | environmental-forensics environmental-testing | arizona | scott-la | non-nelap-states | arizona-department-of-health-services-az-dhs | ||

| Scott, LA | SGS Scott Arkansas | Non-NELAP States | Arkansas Department of Environmental Quality (AR DEQ) | environmental-forensics environmental-testing | arkansas | scott-la | non-nelap-states | arkansas-department-of-environmental-quality-ar-deq | ||

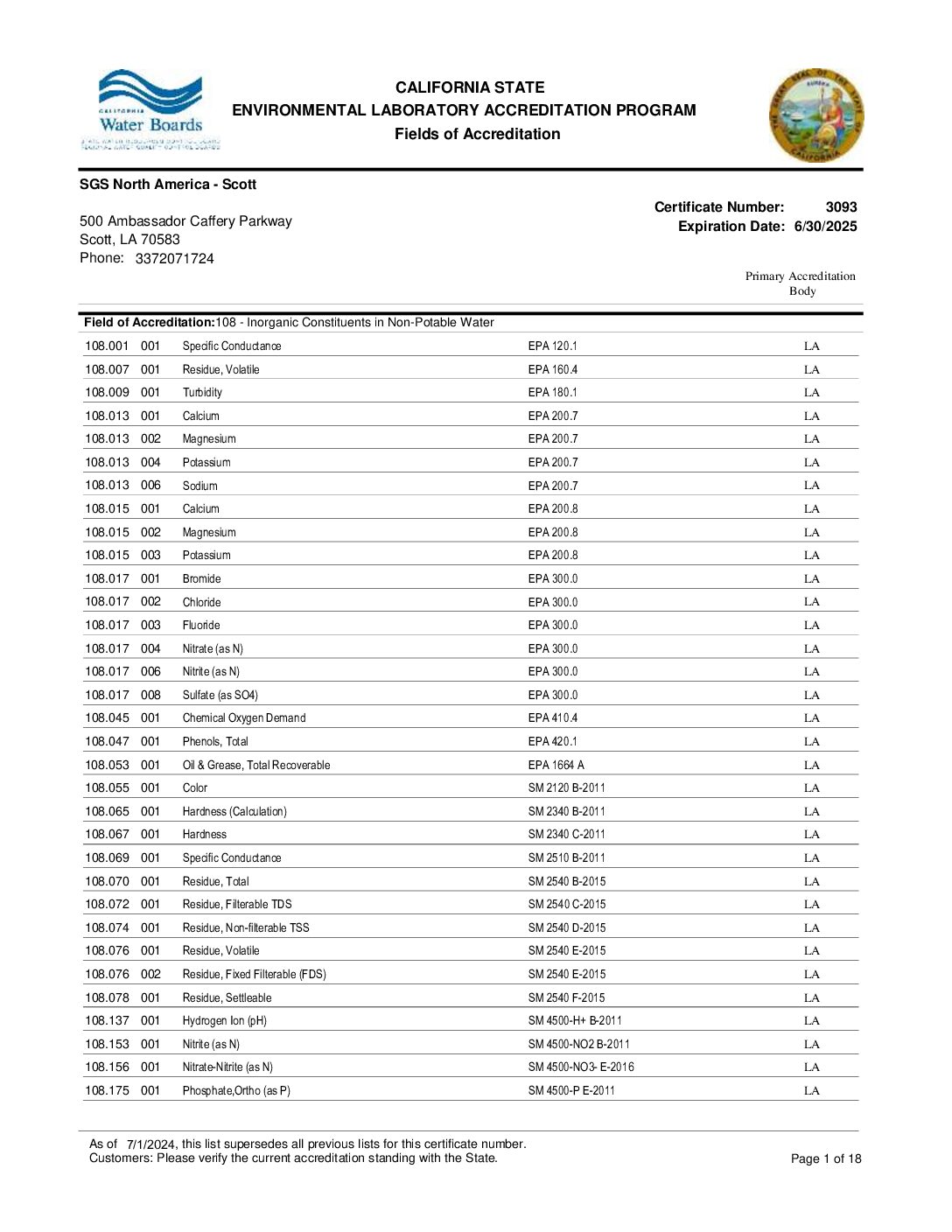

| Scott, LA | SGS Scott California | TNI - 2 (California) | California Waterboards | environmental-forensics environmental-testing | california | scott-la | tni-2-california | california-waterboards | ||

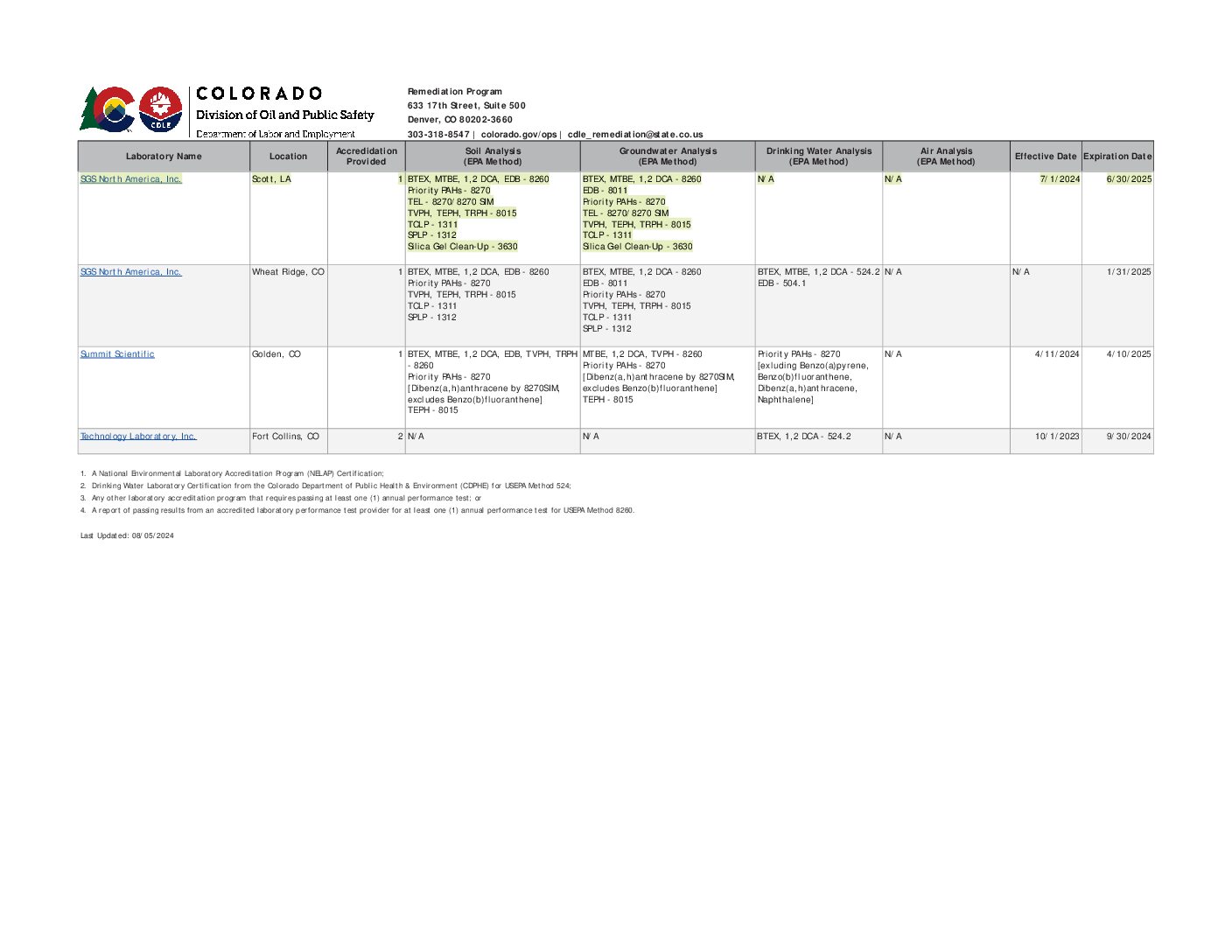

| Scott, LA | SGS Scott Colorado CODOPS Cert | Non-NELAP States | Colorado Division of Oil and Public Safety (CODOPS) | environmental-forensics environmental-testing | colorado | scott-la | non-nelap-states | colorado-division-of-oil-and-public-safety-codops | ||

| Scott, LA | SGS Scott Florida | TNI/NELAP | Florida Department of Health (FL DOH) | environmental-forensics environmental-testing | florida | scott-la | tni-nelap | florida-department-of-health-fl-doh | ||

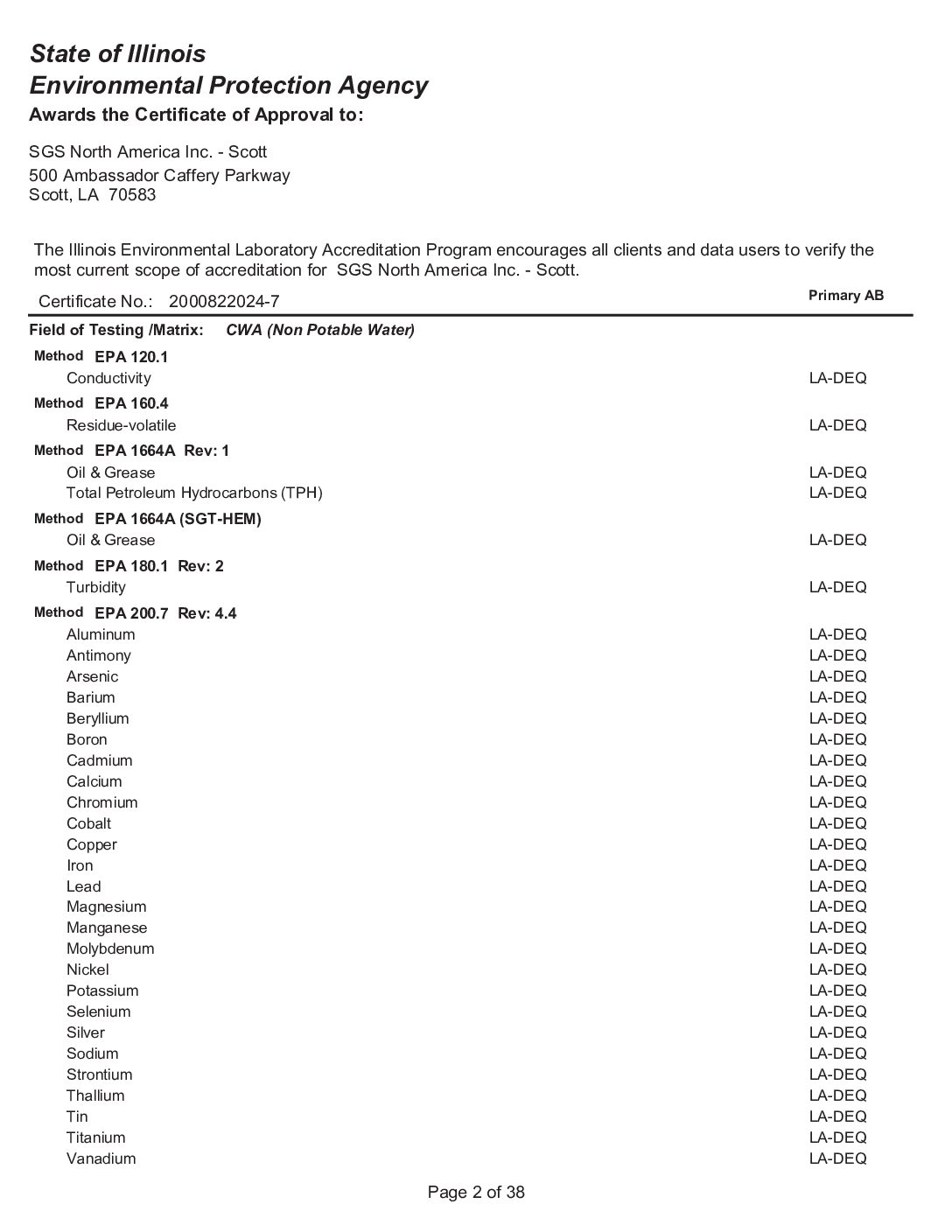

| Scott, LA | SGS Scott Illinois | TNI/NELAP | Illinois Environmental Protection Agency (IL EPA) | environmental-forensics environmental-testing | illinois | scott-la | tni-nelap | illinois-environmental-protection-agency-il-epa | ||

| Scott, LA | SGS Scott Kentucky UST | Non-NELAP States | Kentucky Division of Waste Management Underground Storage Tank Branch (KY UST) | environmental-forensics environmental-testing | kentucky | scott-la | non-nelap-states | kentucky-division-of-waste-management-underground-storage-tank-branch-ky-ust | ||

| Scott, LA | SGS Scott Kentucky WW | Non-NELAP States | Kentucky Energy and Environment Cabinet (KY EEC) | environmental-forensics environmental-testing | kentucky | scott-la | non-nelap-states | kentucky-energy-and-environment-cabinet-ky-eec | ||

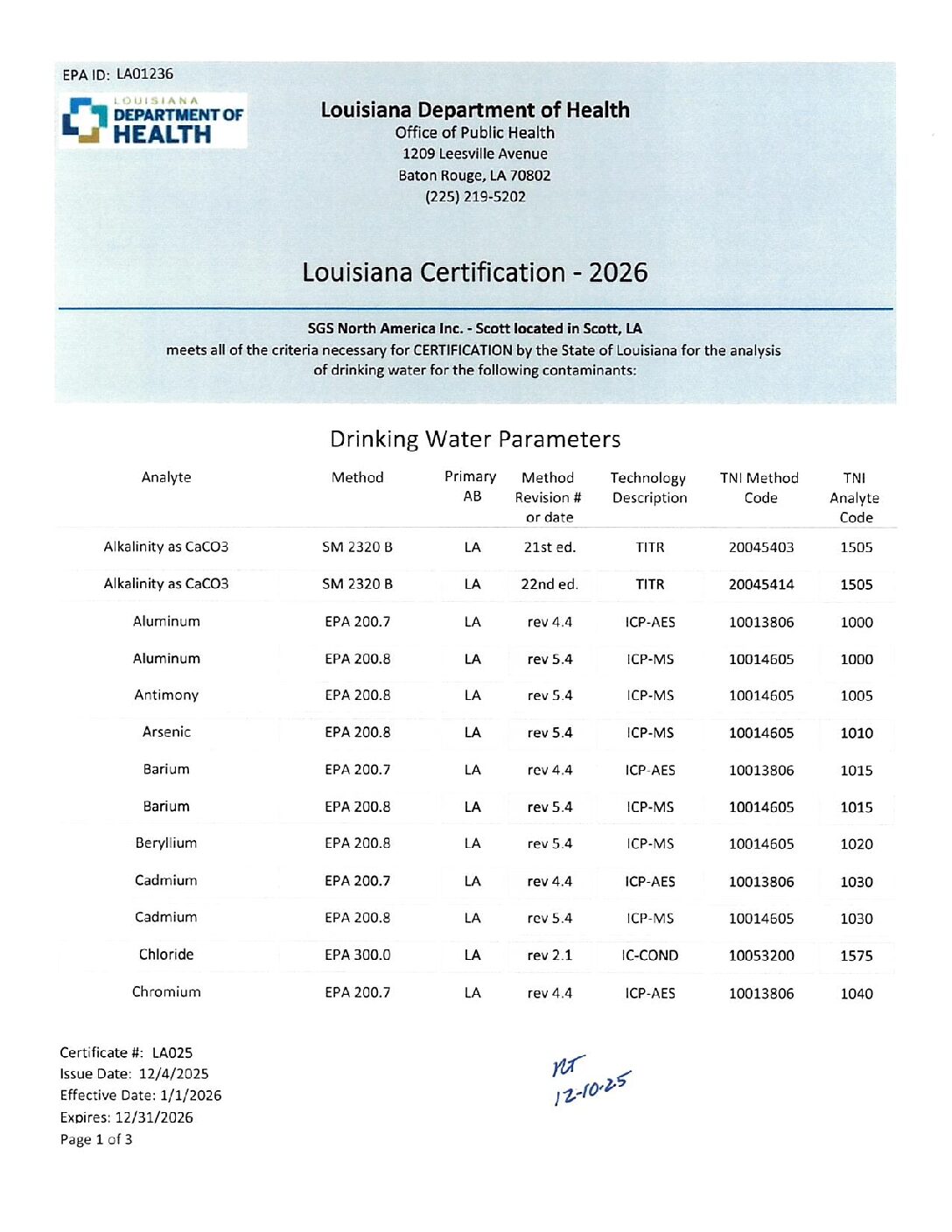

| Scott, LA | SGS Scott Louisiana DW | Drinking Water | Louisiana Department of Health (LA DOH) | environmental-forensics environmental-testing | louisiana | scott-la | drinking-water | louisiana-department-of-health-la-doh | ||

| Scott, LA | SGS Scott Louisiana DEQ | TNI/NELAP | Louisiana Department of Environmental Quality (LDEQ) | environmental-forensics environmental-testing | louisiana | scott-la | tni-nelap | louisiana-department-of-environmental-quality-ldeq | ||

| Scott, LA | SGS Scott New Jersey | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | environmental-forensics environmental-testing | new-jersey | scott-la | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

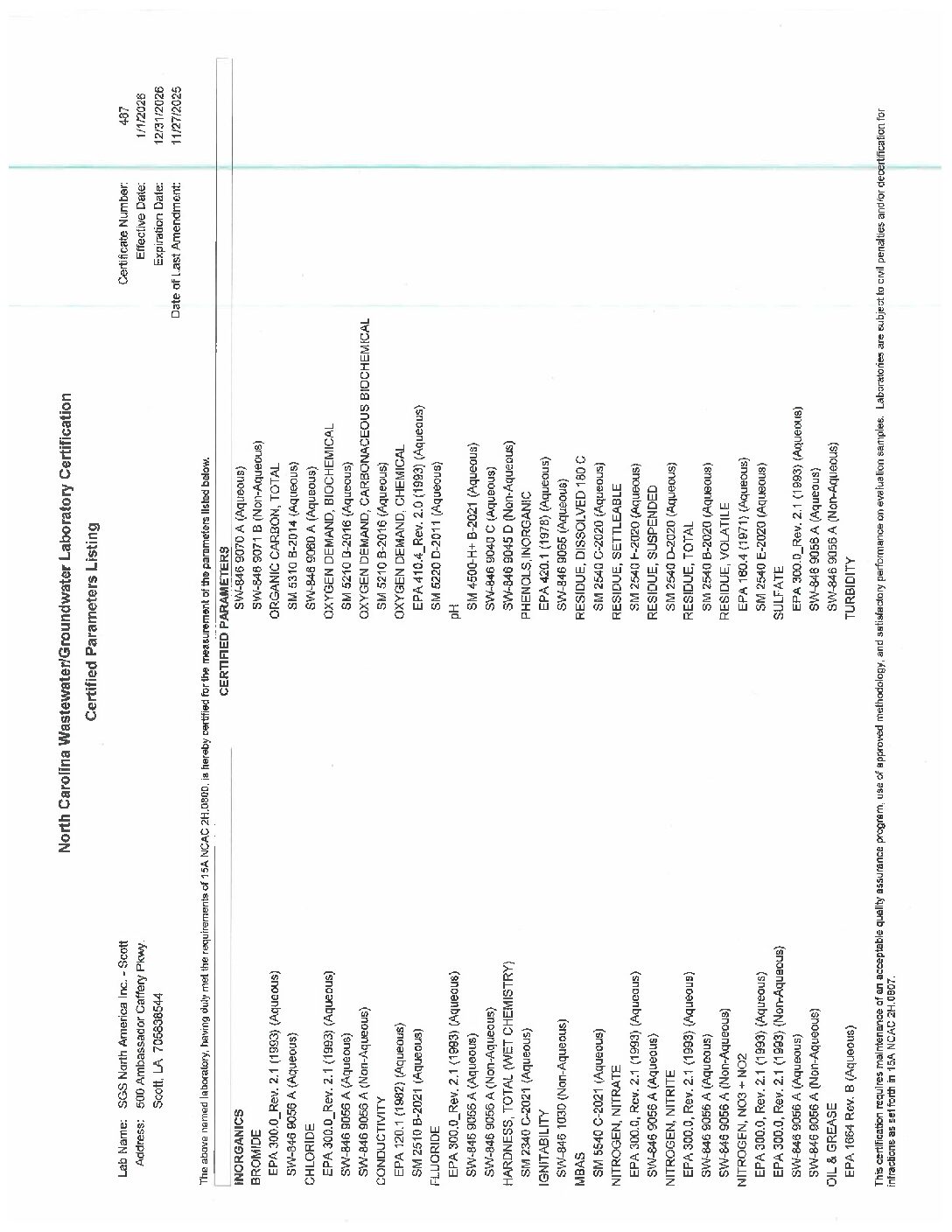

| Scott, LA | SGS Scott North Carolina | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | environmental-forensics environmental-testing | scott-la | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

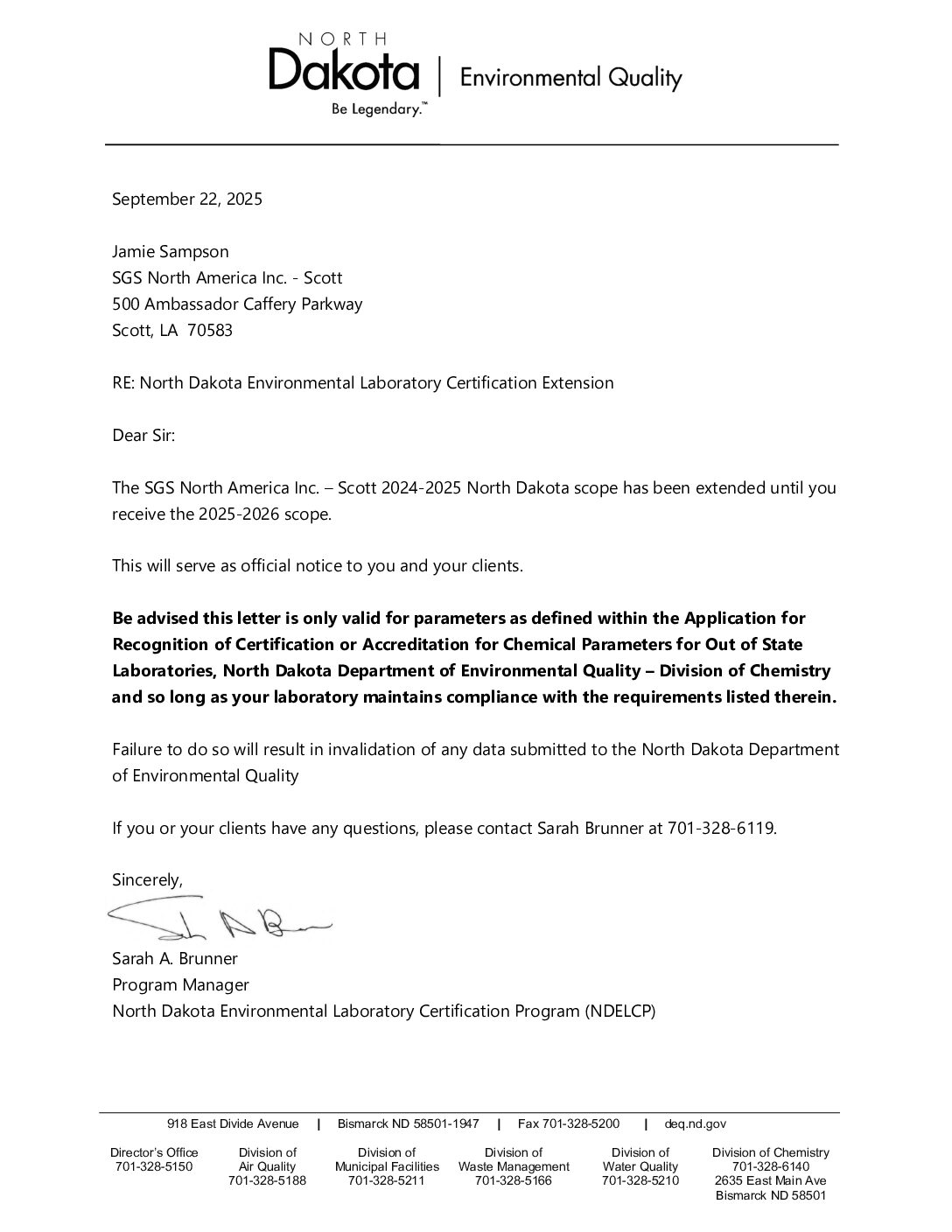

| Scott, LA | SGS Scott North Dakota | Non-NELAP States | North Dakota State Department of Health (ND DOH) | environmental-forensics environmental-testing | north-dakota | scott-la | non-nelap-states | north-dakota-state-department-of-health-nd-doh | ||

| Scott, LA | SGS Scott Oklahoma | TNI/NELAP | Oklahoma Department of Environmental Quality (OK DEQ) | environmental-forensics environmental-testing | oklahoma | scott-la | tni-nelap | oklahoma-department-of-environmental-quality-ok-deq | ||

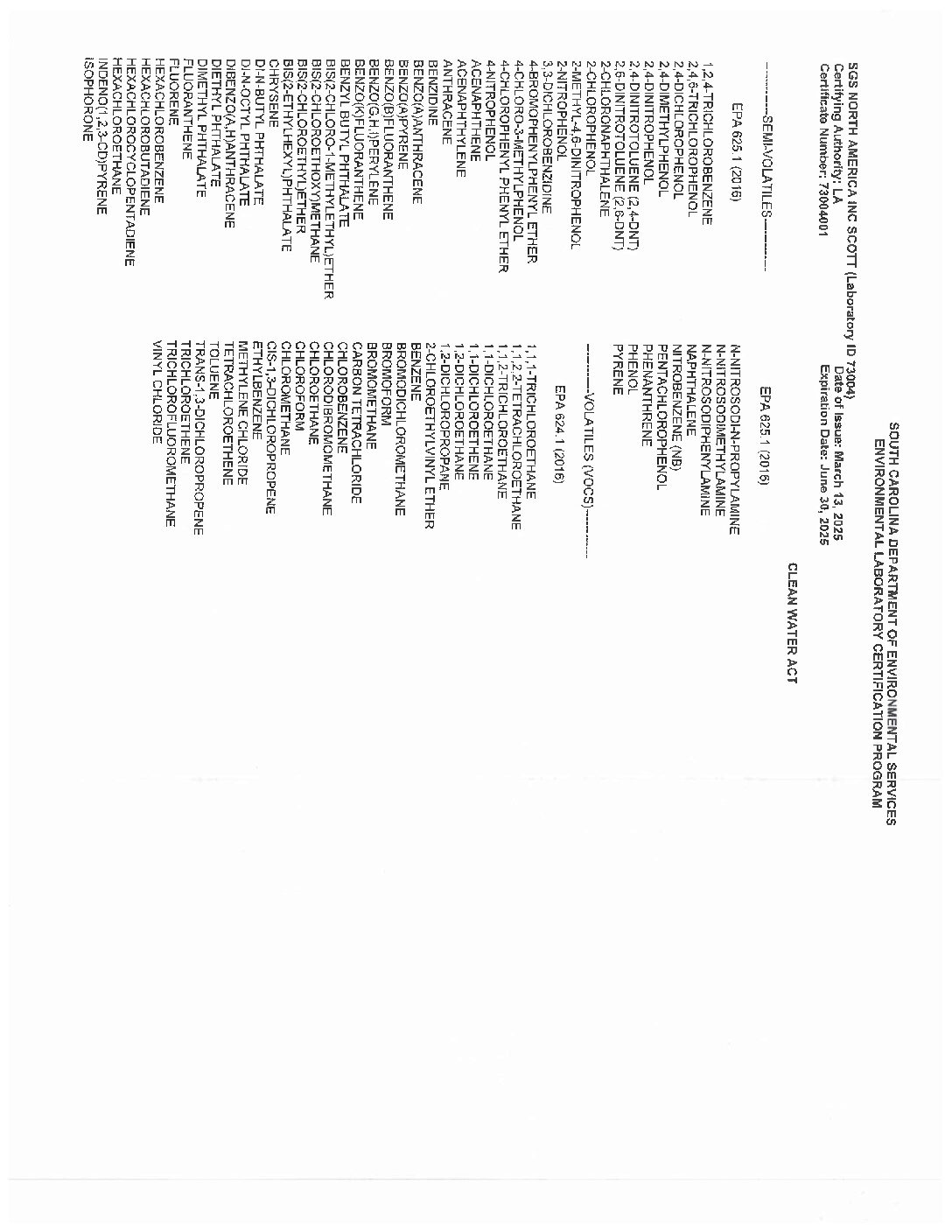

| Scott, LA | SGS Scott South Carolina | Non-NELAP States | South Carolina Environmental Laboratory Certification Program (SC ELCP) | environmental-forensics environmental-testing | south-carolina | scott-la | non-nelap-states | south-carolina-environmental-laboratory-certification-program-sc-elcp | ||

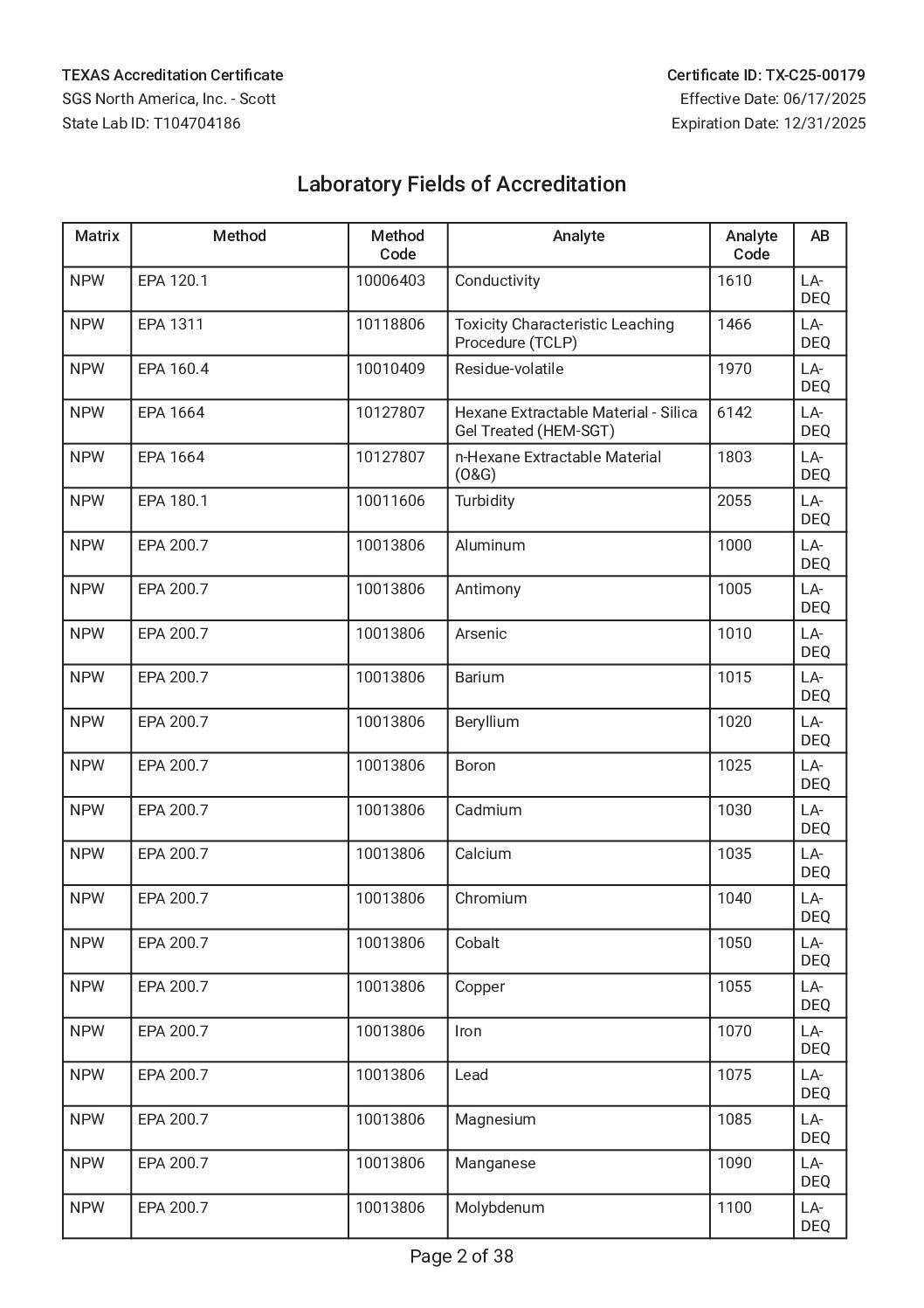

| Scott, LA | SGS Scott Texas | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | environmental-forensics environmental-testing | texas | scott-la | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Scott, LA | SGS Scott Washington | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | environmental-forensics environmental-testing | washington | scott-la | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

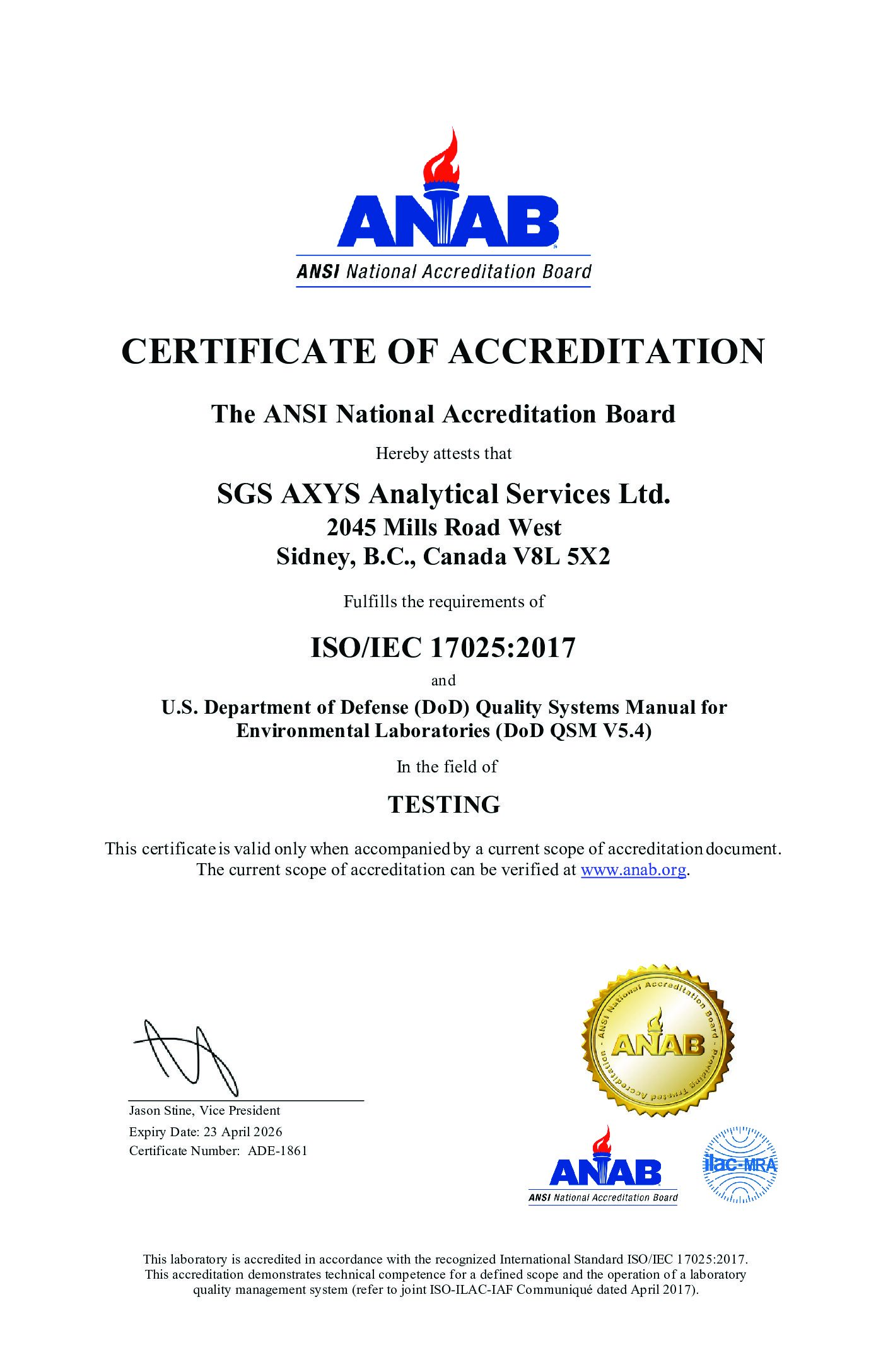

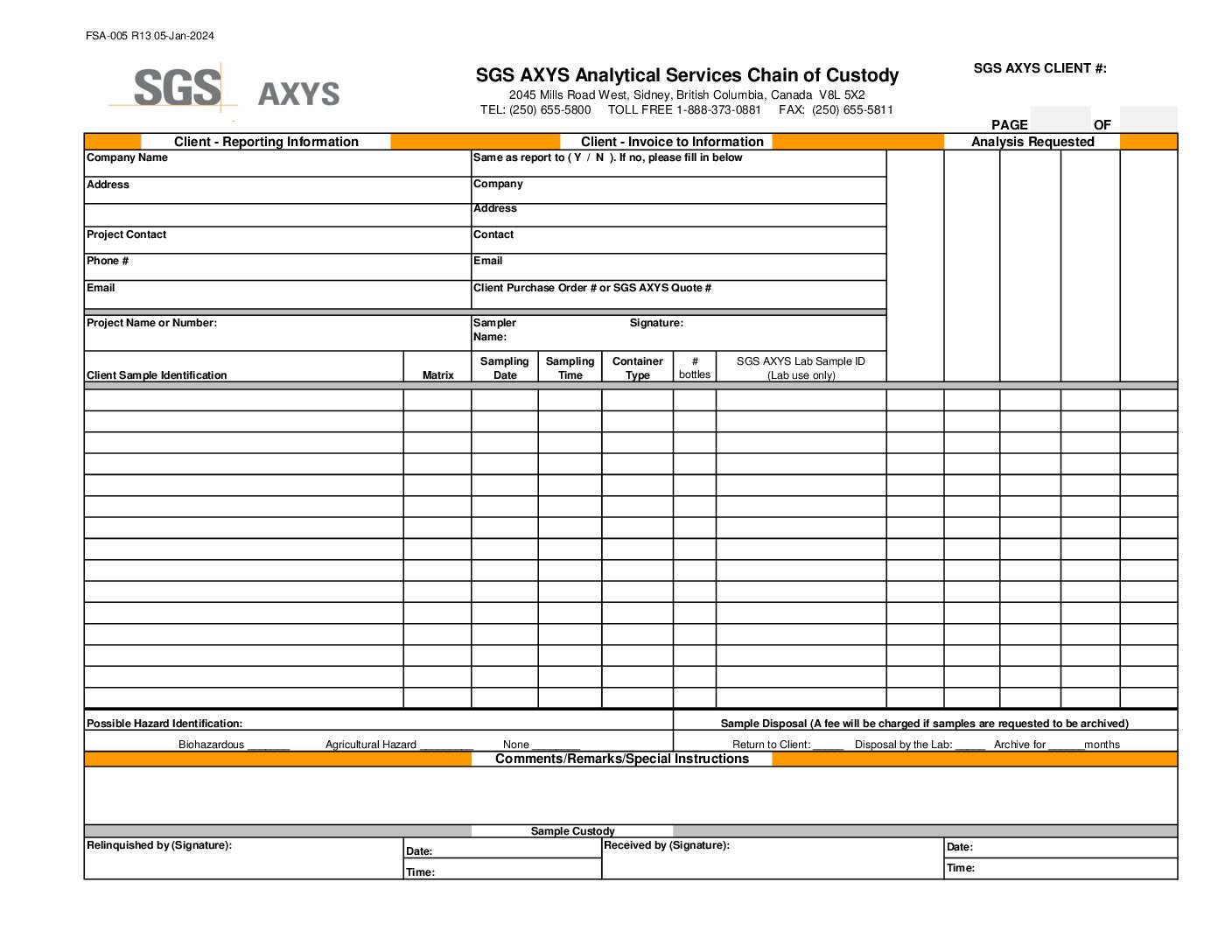

| Sidney, BC | SGS AXYS ANAB US DoD cert and scope | DOD | ANSI National Accreditation Board (ANAB) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | not-applicable | sidney-bc | dod | ansi-national-accreditation-board-anab | ||

| Sidney, BC | SGS AXYS ANAB US DOE cert and scope | DOD, DOECAP, ISO/IEC 17025:2017 | ANSI National Accreditation Board (ANAB) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | not-applicable | sidney-bc | dod doecap iso-iec-170252017 | ansi-national-accreditation-board-anab | ||

| Sidney, BC | SGS AXYS Alaska Lab Approval | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | alaska | sidney-bc | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Sidney, BC | SGS AXYS California cert and scope | TNI - 2 (California) | California Waterboards | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | california | sidney-bc | tni-2-california | california-waterboards | ||

| Sidney, BC | SGS AXYS CALA cert and scope | ISO/IEC 17025:2017 | Canadian Association for Laboratory Accreditation (CALA) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | british-columbia canada | sidney-bc | iso-iec-170252017 | canadian-association-for-laboratory-accreditation-cala | ||

| Sidney, BC | SGS AXYS Florida cert and scope | TNI/NELAP | Florida Department of Health (FL DOH) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | florida | sidney-bc | tni-nelap | florida-department-of-health-fl-doh | ||

| Sidney, BC | SGS AXYS Maine cert and scope | Non-NELAP States | Maine Laboratory Accreditation Program (ME LAP) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | maine | sidney-bc | non-nelap-states | maine-laboratory-accreditation-program-me-lap | ||

| Sidney, BC | SGS AXYS Minnesota cert and scope | TNI/NELAP | Minnesota Environmental Laboratory Accreditation Program (MN ELAP) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | minnesota | sidney-bc | tni-nelap | minnesota-environmental-laboratory-accreditation-program-mn-elap | ||

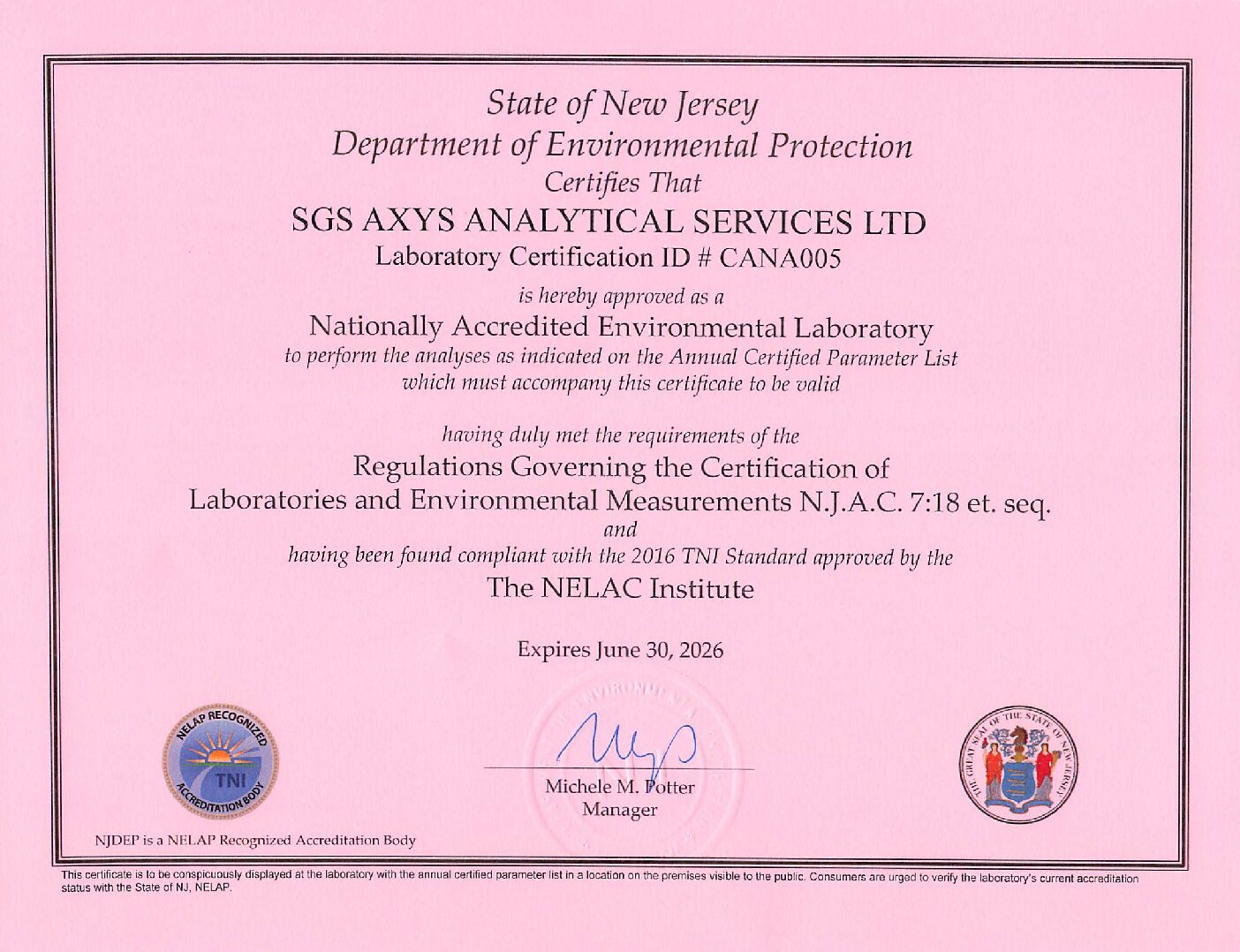

| Sidney, BC | SGS AXYS New Jersey cert and scope | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | new-jersey | sidney-bc | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

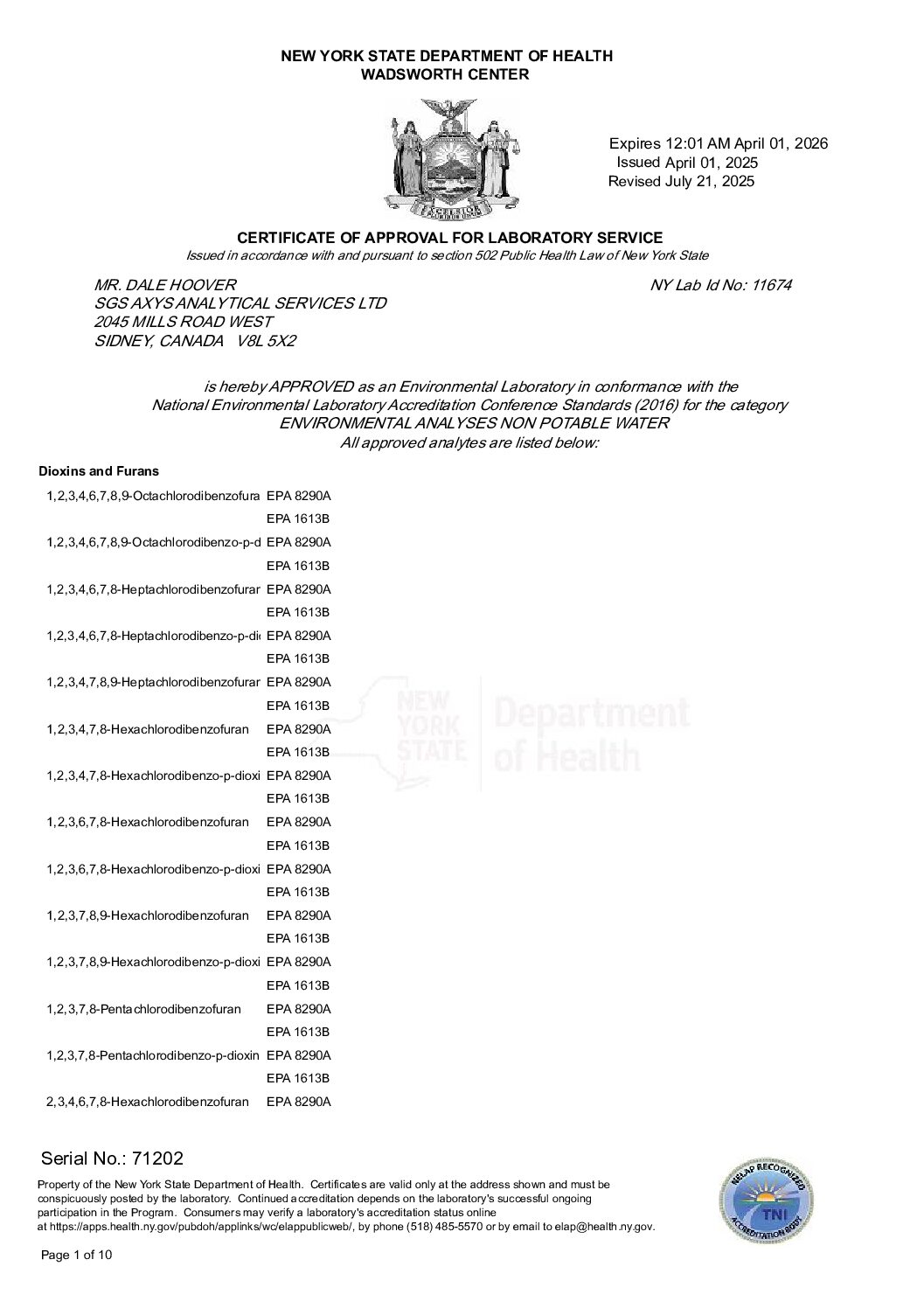

| Sidney, BC | SGS AXYS New York cert and scope | TNI/NELAP | New York State Department of Health (NY DOH) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | new-york | sidney-bc | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Sidney, BC | SGS AXYS Pennsylvania cert and scope | TNI/NELAP | Pennsylvania Department of Environmental Protection (PA DEP) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | pennsylvania | sidney-bc | tni-nelap | pennsylvania-department-of-environmental-protection-pa-dep | ||

| Sidney, BC | SGS AXYS Virginia cert and scope | TNI/NELAP | Virginia Department of General Services (VA DGS) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | virginia | sidney-bc | tni-nelap | virginia-department-of-general-services-va-dgs | ||

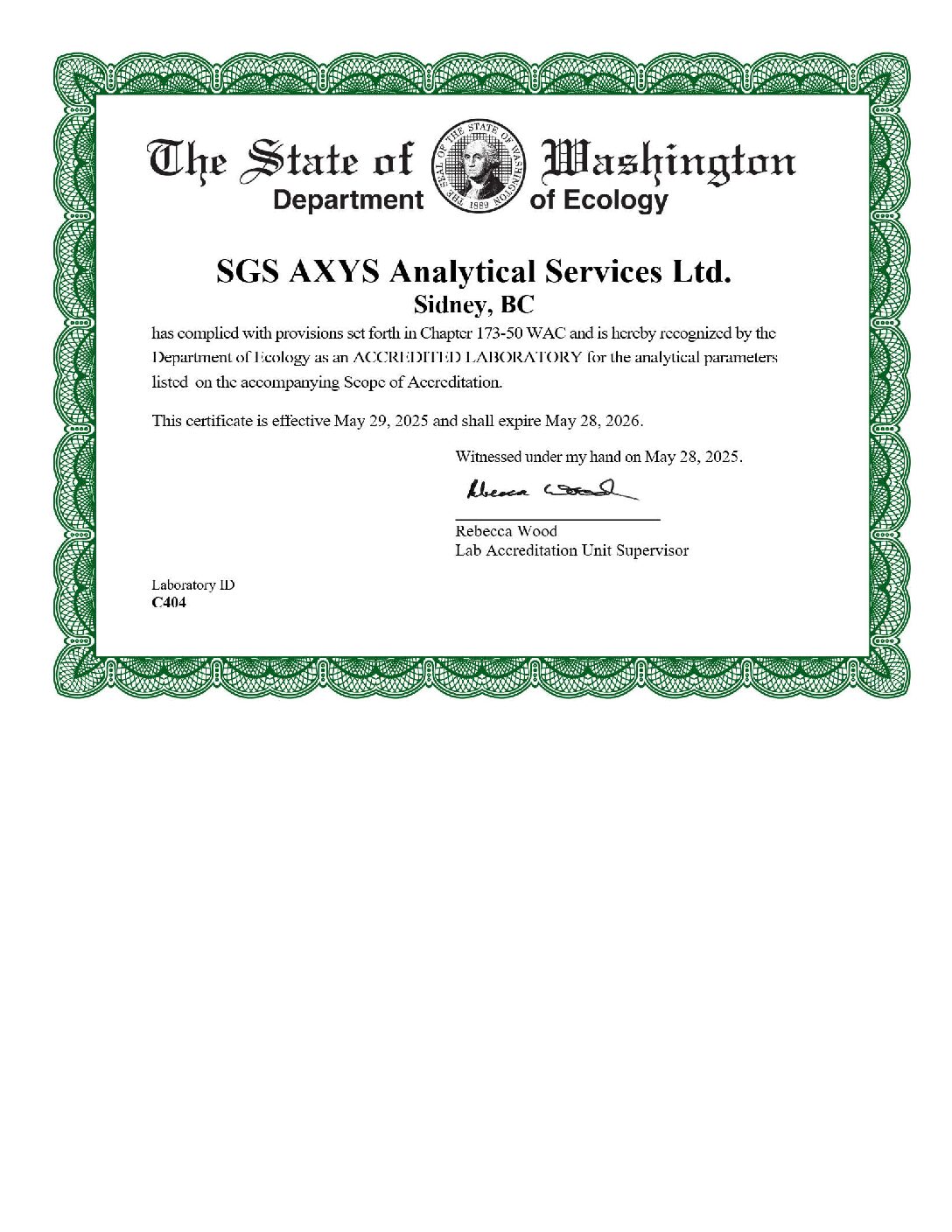

| Sidney, BC | SGS AXYS Washington cert and scope | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | emerging-contaminants passive-and-high-volume pfas-analysis ultratrace | washington | sidney-bc | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

| Syracuse, NY | SGS Galson AIHA | AIHA | AIHA Laboratory Accreditation Program (AIHA LAP) | air-quality emergency-response industrial-hygiene | not-applicable | syracuse-ny | aiha | aiha-laboratory-accreditation-program-aiha-lap | ||

| Syracuse, NY | SGS Galson New York | TNI/NELAP | New York State Department of Health (NY DOH) | air-quality emergency-response industrial-hygiene | new-york | syracuse-ny | tni-nelap | new-york-state-department-of-health-ny-doh | ||

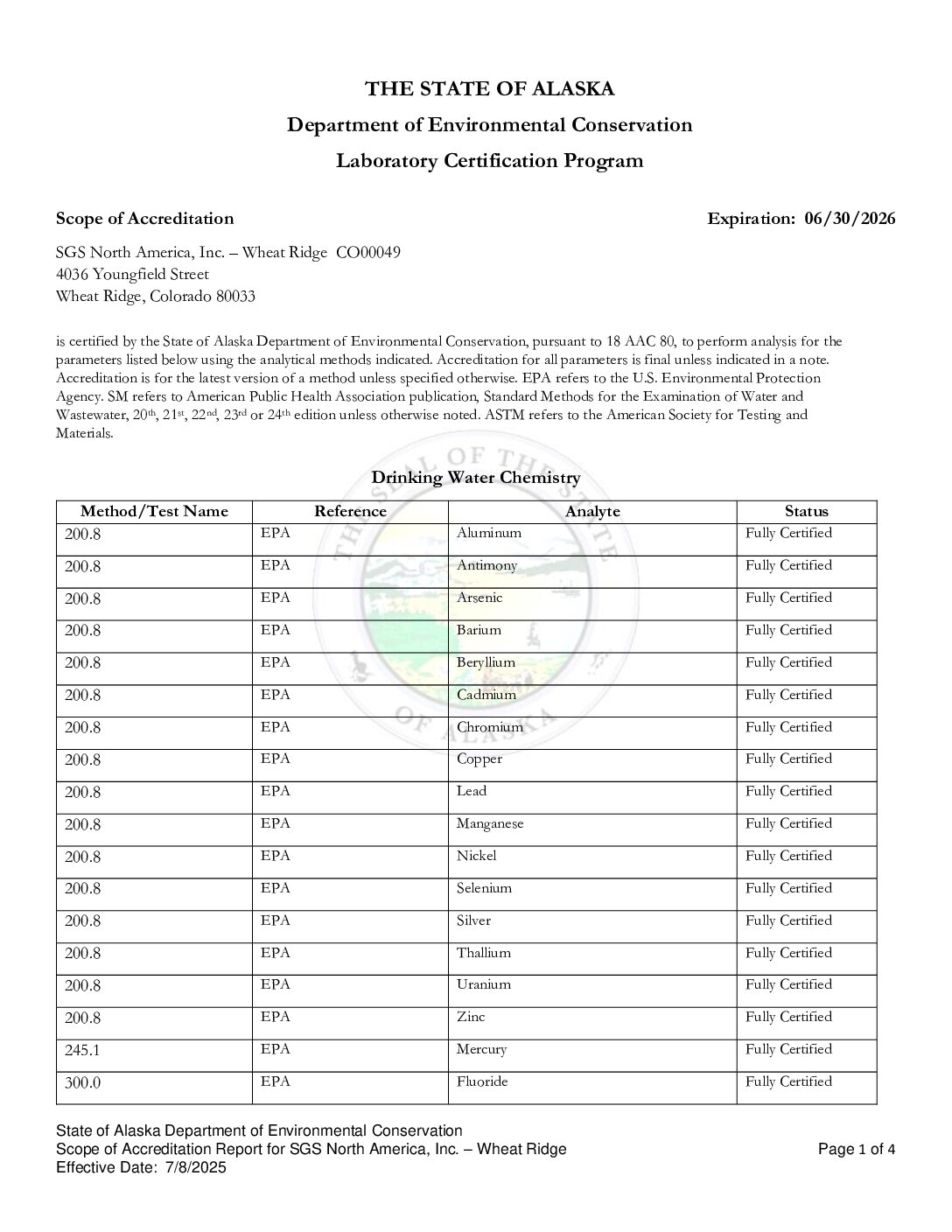

| Wheat Ridge, CO | SGS Wheat Ridge Alaska DW | Drinking Water | Alaska Department of Environmental Conservation (AK DEC) | environmental-testing | alaska | wheat-ridge-co | drinking-water | alaska-department-of-environmental-conservation-ak-dec | ||

| Wheat Ridge, CO | SGS Wheat Ridge California | TNI - 2 (California) | California Waterboards | environmental-testing | california | wheat-ridge-co | tni-2-california | california-waterboards | ||

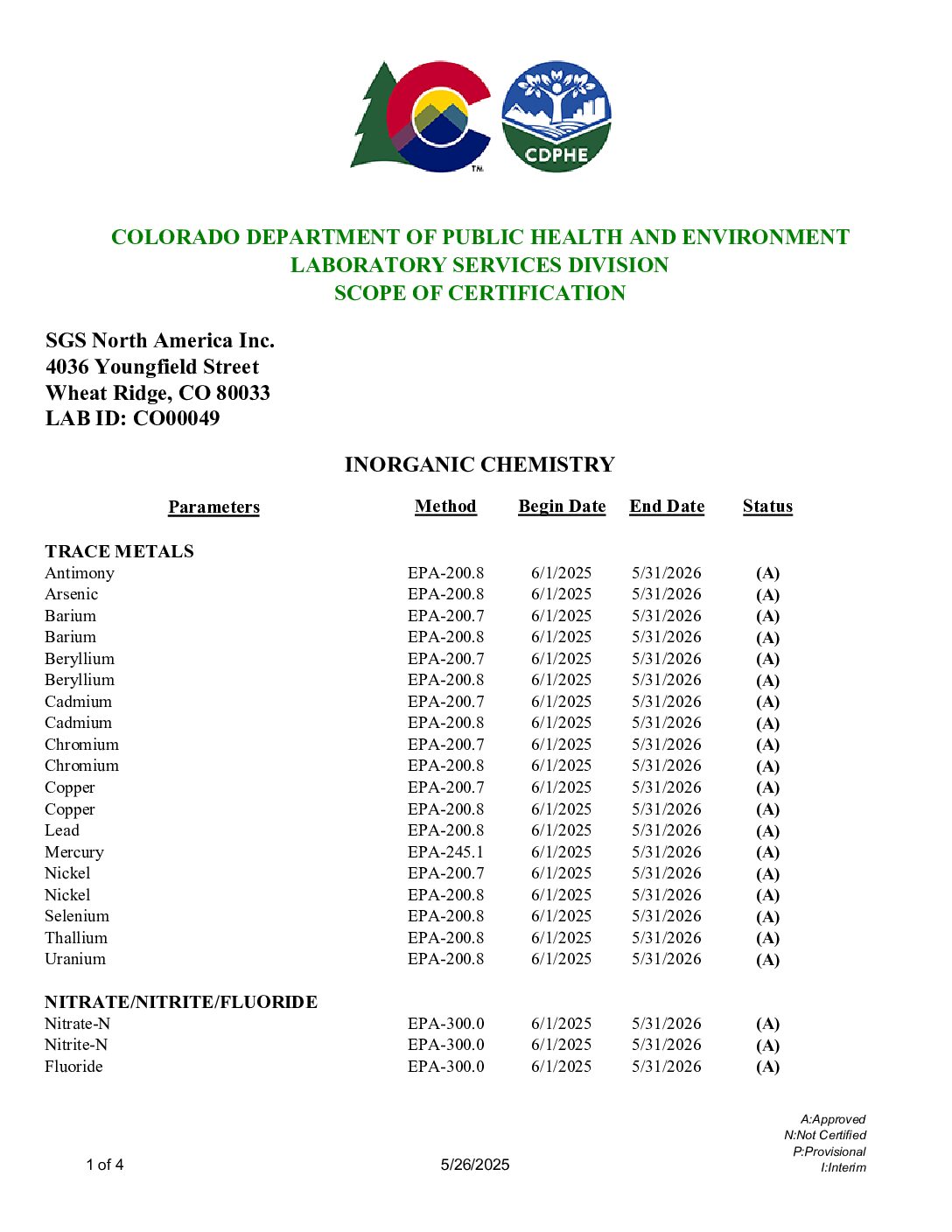

| Wheat Ridge, CO | SGS Wheat Ridge Colorado | Drinking Water | Colorado Department of Public Health and Environment (CODPHE) | environmental-testing | colorado | wheat-ridge-co | drinking-water | colorado-department-of-public-health-and-environment-codphe | ||

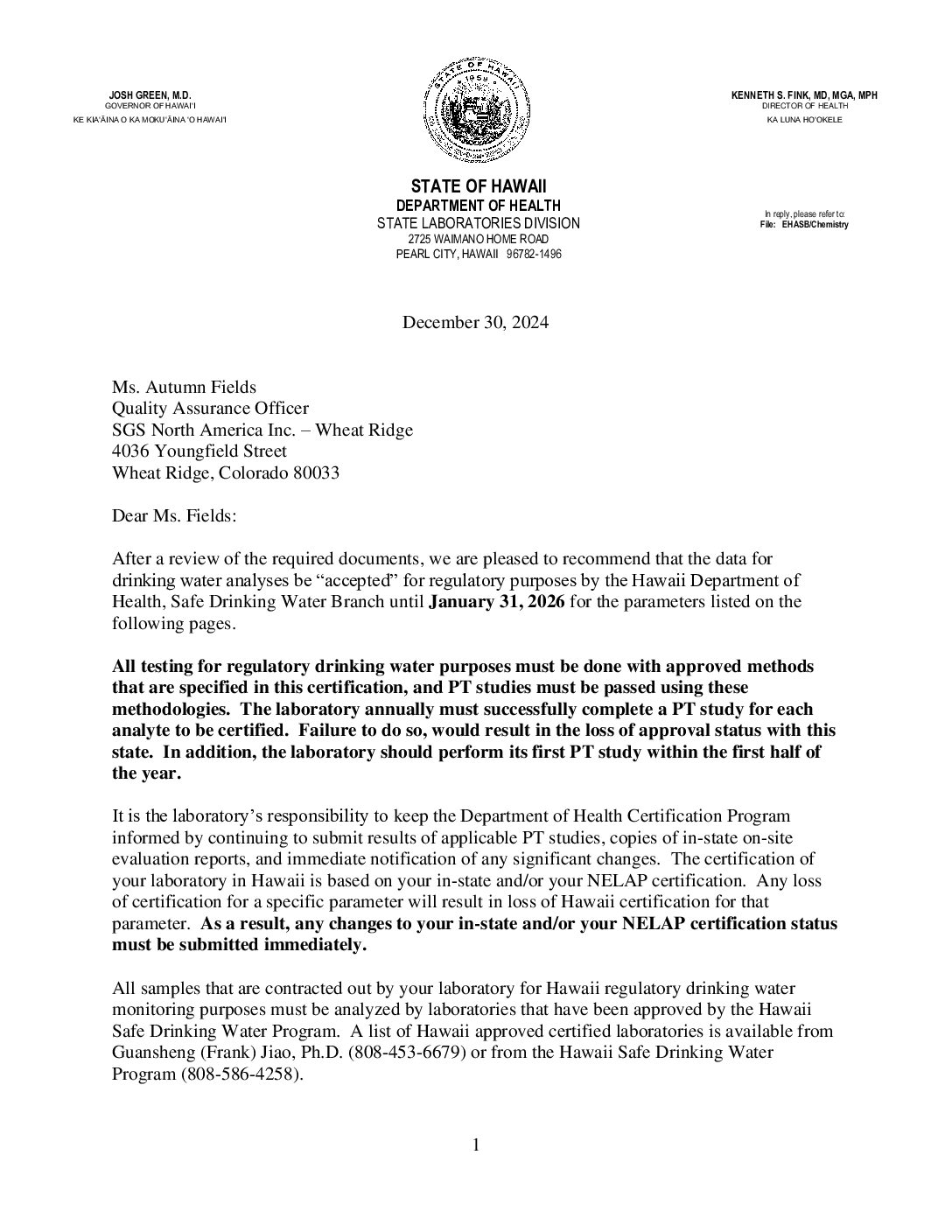

| Wheat Ridge, CO | SGS Wheat Ridge Hawaii | Drinking Water | State of Hawaii Department of Health (HI DOH) | environmental-testing | hawaii | wheat-ridge-co | drinking-water | state-of-hawaii-department-of-health-hi-doh | ||

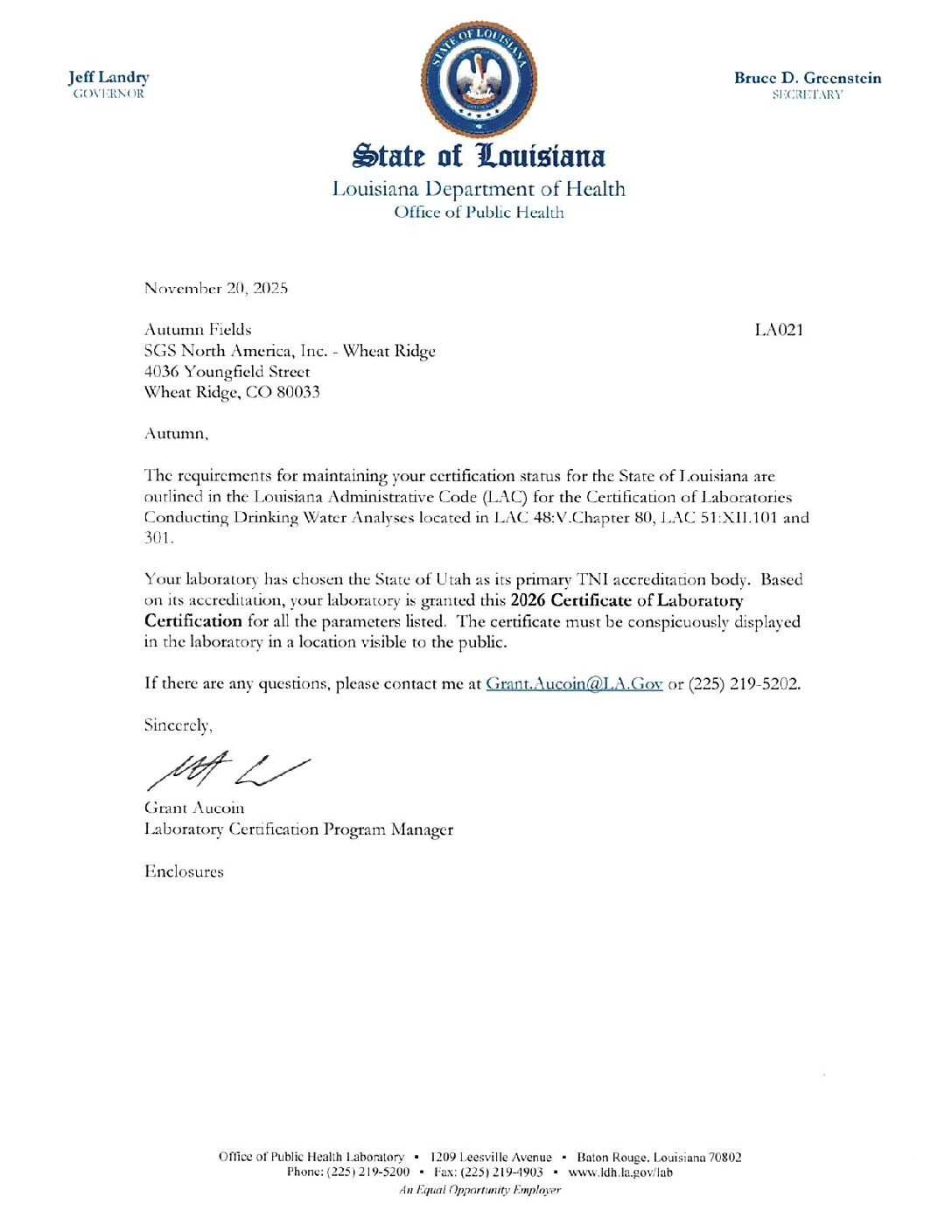

| Wheat Ridge, CO | SGS Wheat Ridge Louisiana | Drinking Water | Louisiana Department of Health (LA DOH) | environmental-testing | louisiana | wheat-ridge-co | drinking-water | louisiana-department-of-health-la-doh | ||

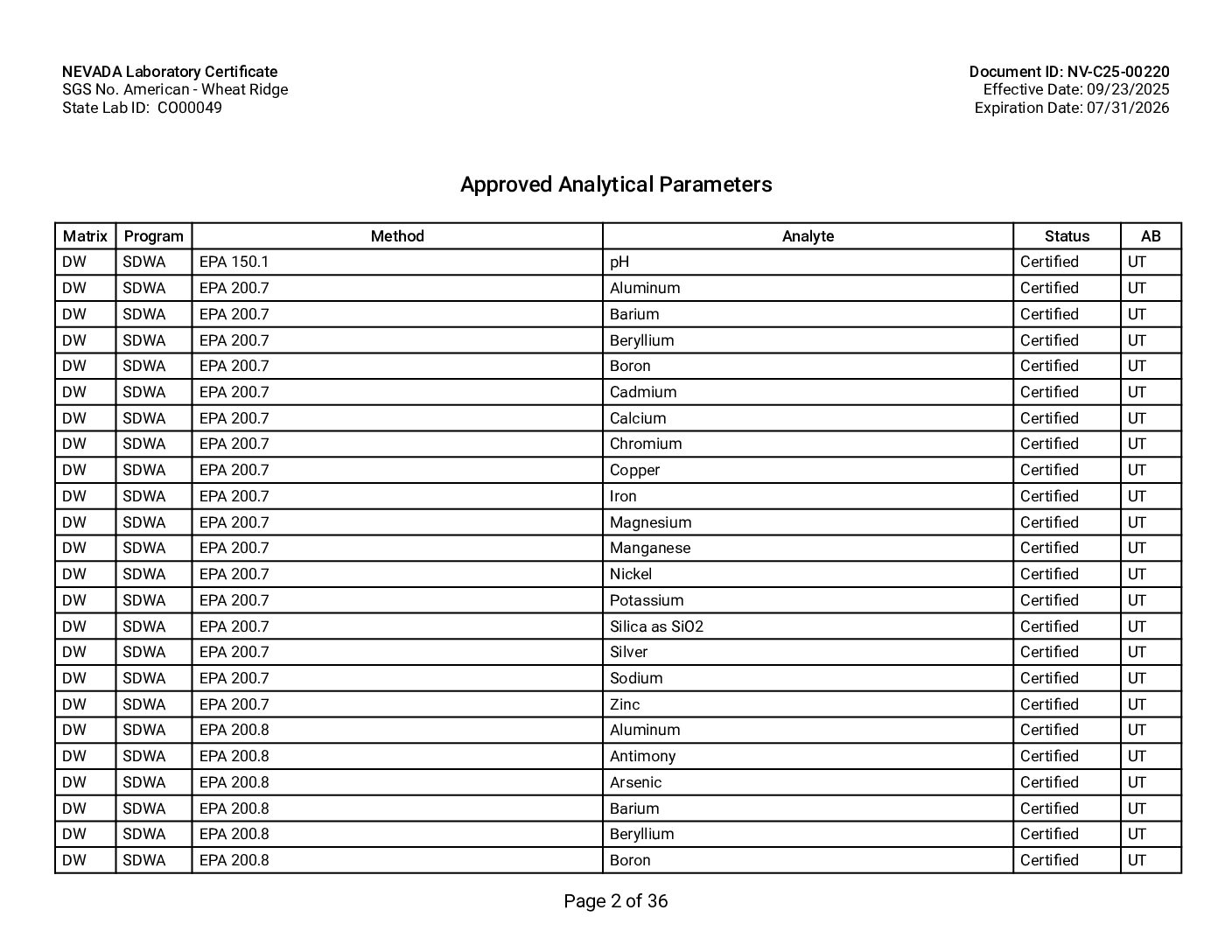

| Wheat Ridge, CO | SGS Wheat Ridge Nevada | Non-NELAP States | Nevada Department of Conservation and Natural Resources (NV DCNR) | environmental-testing | nevada | wheat-ridge-co | non-nelap-states | nevada-department-of-conservation-and-natural-resources-nv-dcnr | ||

| Wheat Ridge, CO | SGS Wheat Ridge New Jersey | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | environmental-testing | new-jersey | wheat-ridge-co | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

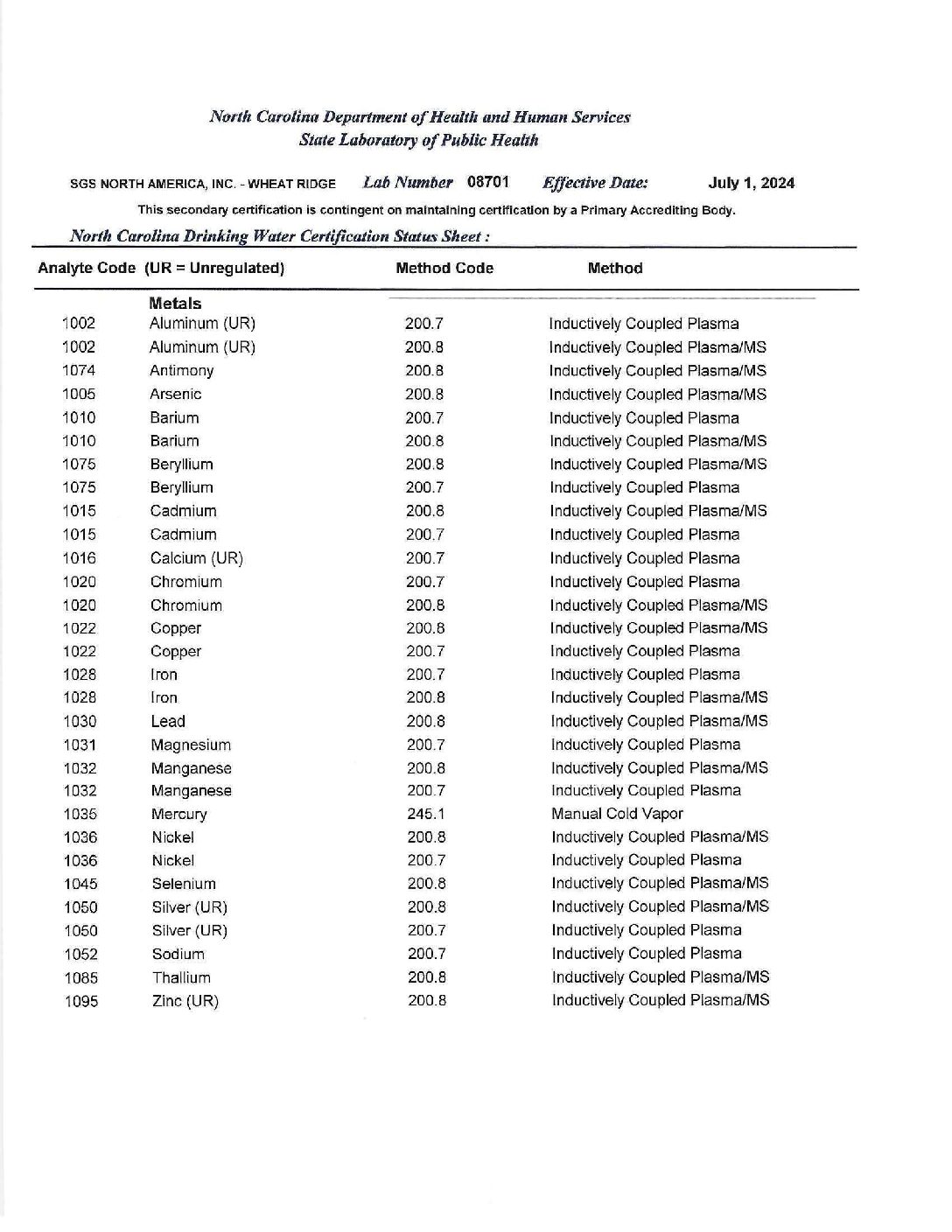

| Wheat Ridge, CO | SGS Wheat Ridge North Carolina | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | environmental-testing | wheat-ridge-co | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

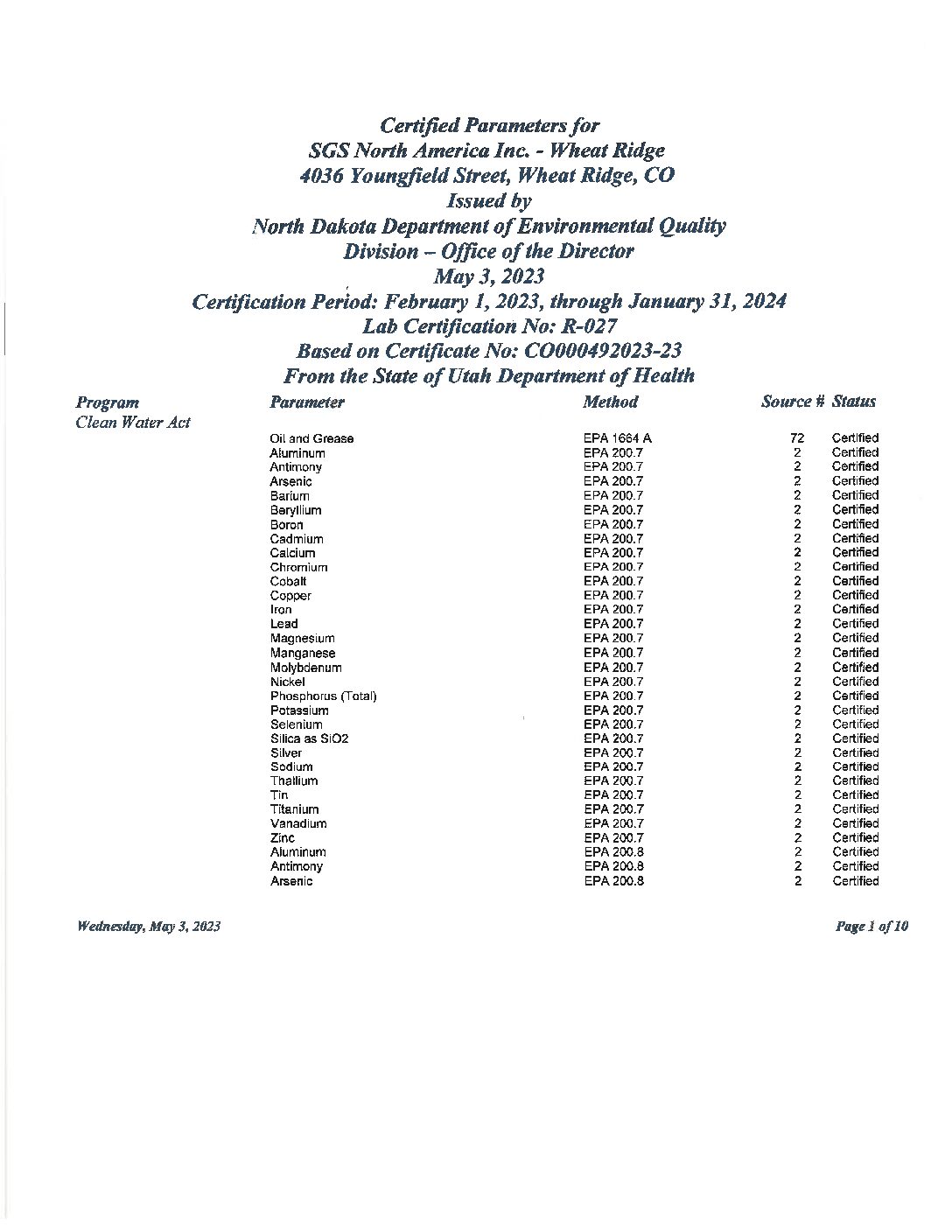

| Wheat Ridge, CO | SGS Wheat Ridge North Dakota | Non-NELAP States | North Dakota State Department of Health (ND DOH) | environmental-testing | north-dakota | wheat-ridge-co | non-nelap-states | north-dakota-state-department-of-health-nd-doh | ||

| Wheat Ridge, CO | SGS Wheat Ridge Texas | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | environmental-testing | texas | wheat-ridge-co | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

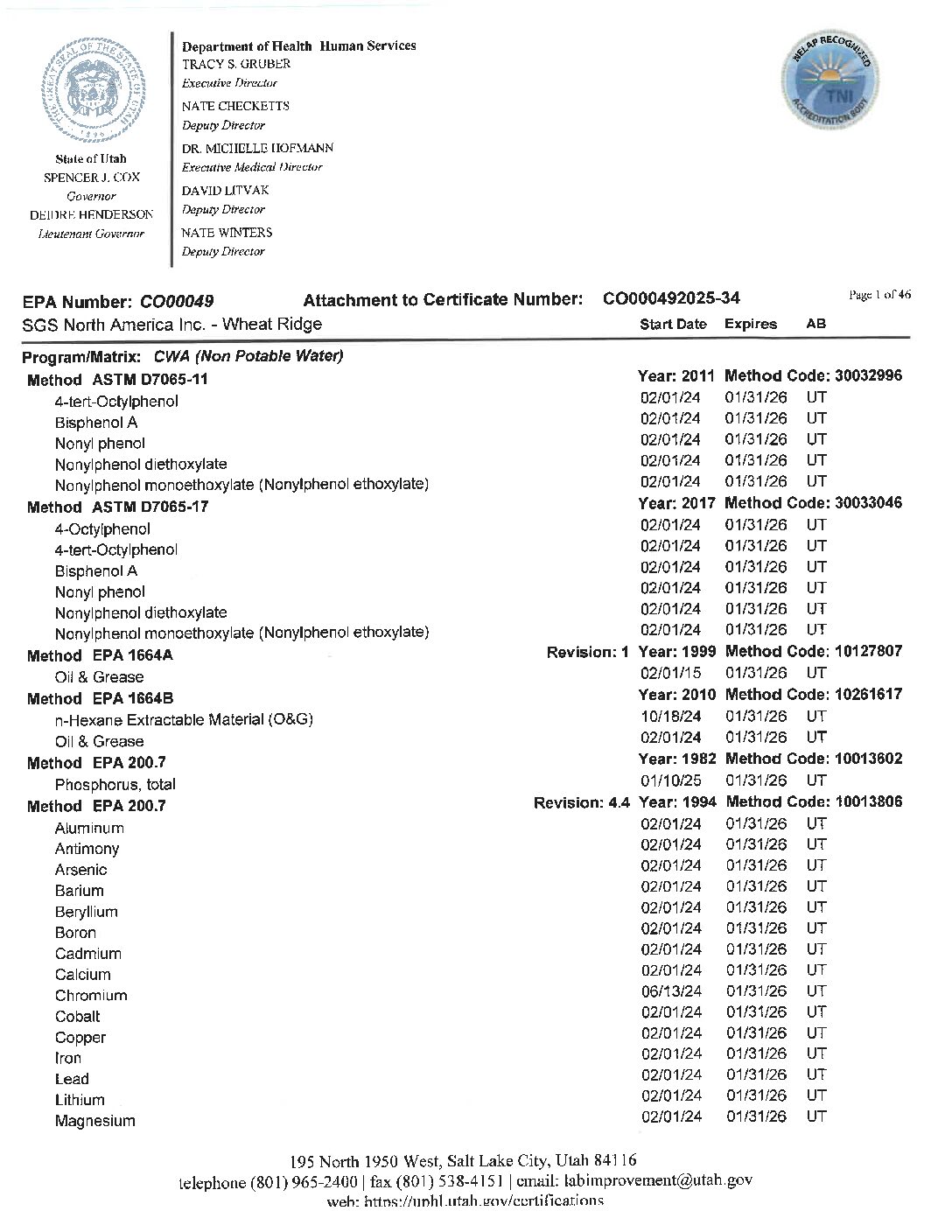

| Wheat Ridge, CO | SGS Wheat Ridge Utah | TNI/NELAP | Utah Department of Health and Human Services (UT DHHS) | environmental-testing | utah | wheat-ridge-co | tni-nelap | utah-department-of-health-and-human-services-ut-dhhs | ||

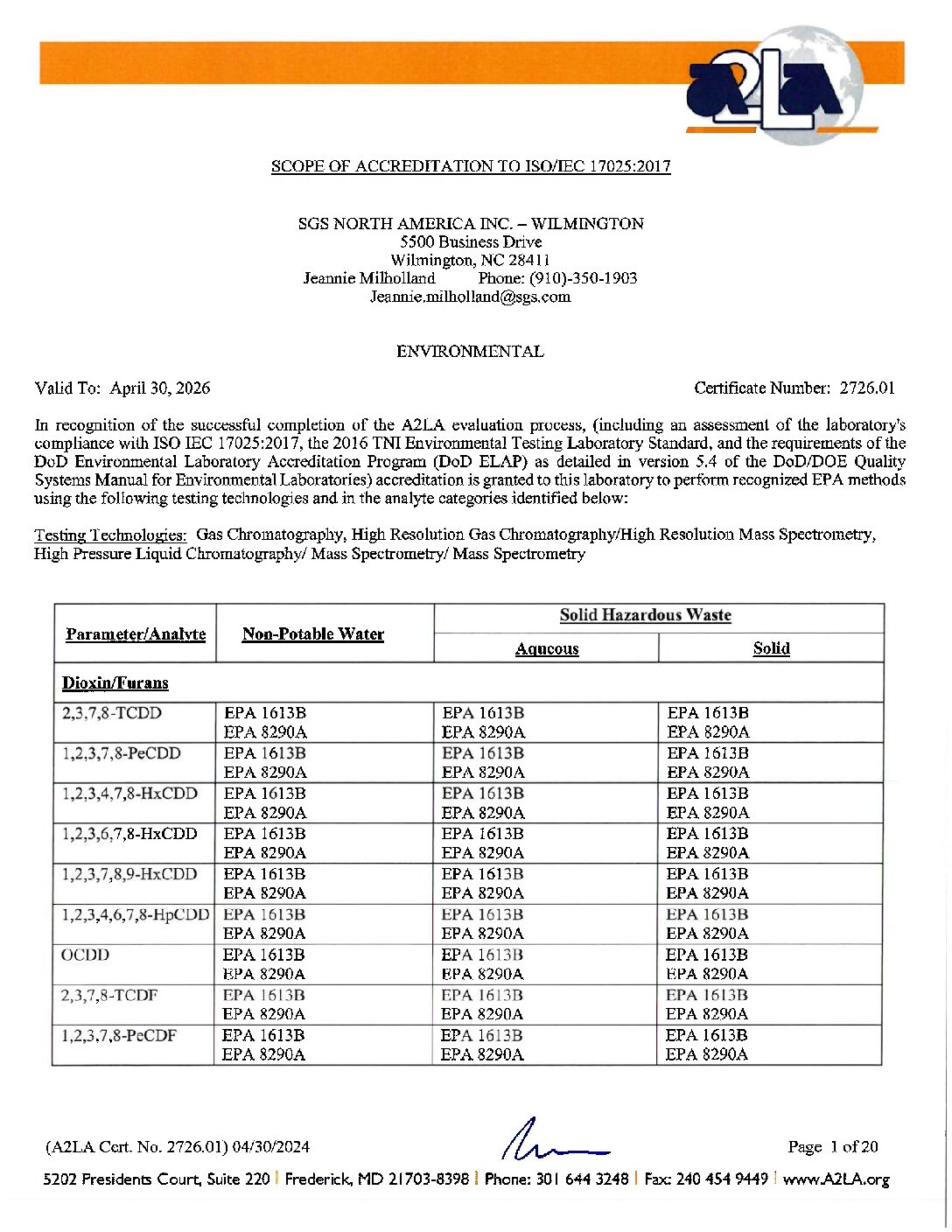

| Wilmington, NC | SGS Wilmington A2LA | DOD, ISO/IEC 17025:2017 | American Association for Laboratory Accreditation (A2LA) | marine-services pfas-analysis ultratrace | not-applicable | wilmington-nc | dod iso-iec-170252017 | american-association-for-laboratory-accreditation-a2la | ||

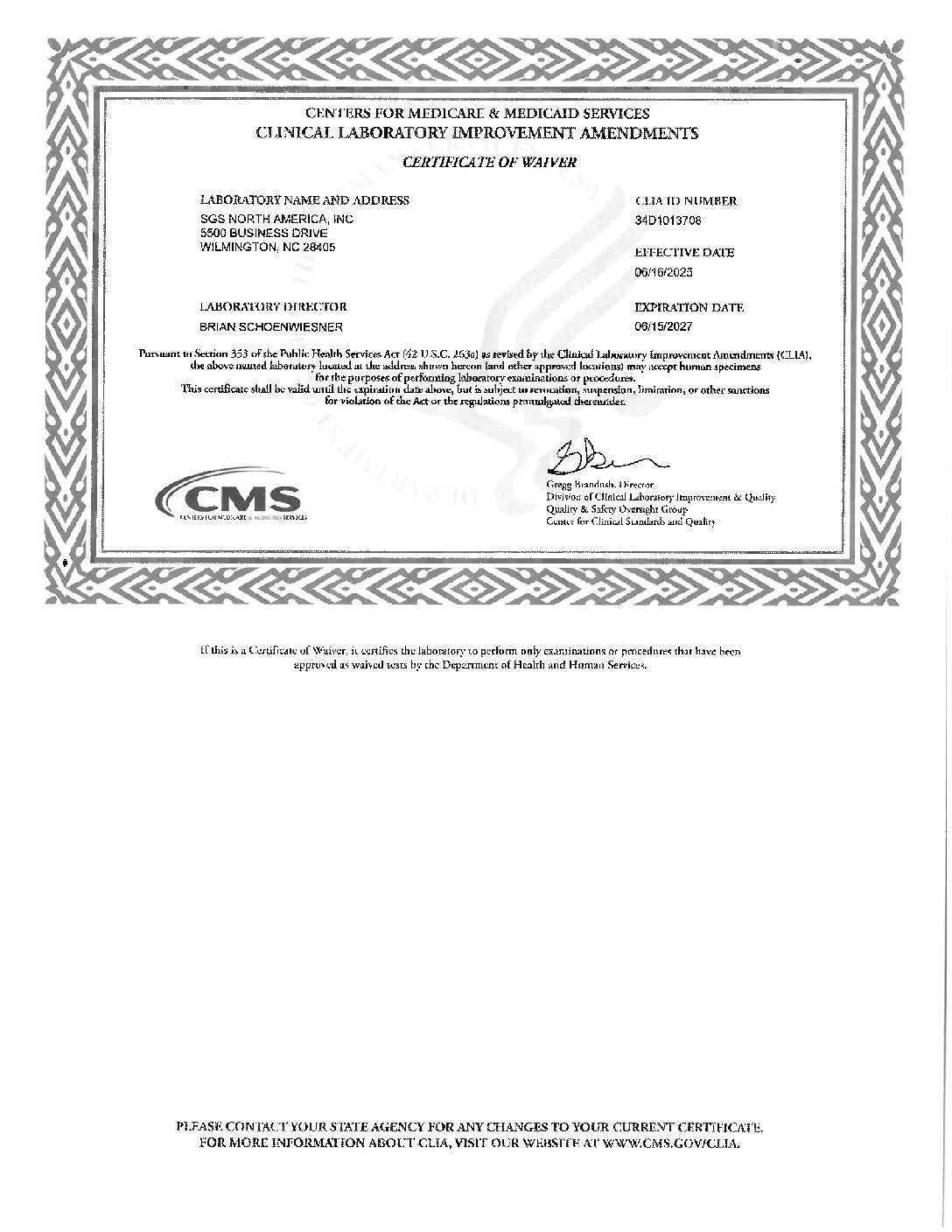

| Wilmington, NC | SGS Wilmington CLIA | Other | Center for Medicare & Medicaid Services - Clinical Laboratory Improvement Amendments (CMS - CLIA) | marine-services pfas-analysis ultratrace | not-applicable | wilmington-nc | other | center-for-medicare-medicaid-services-clinical-laboratory-improvement-amendments-cms-clia | ||

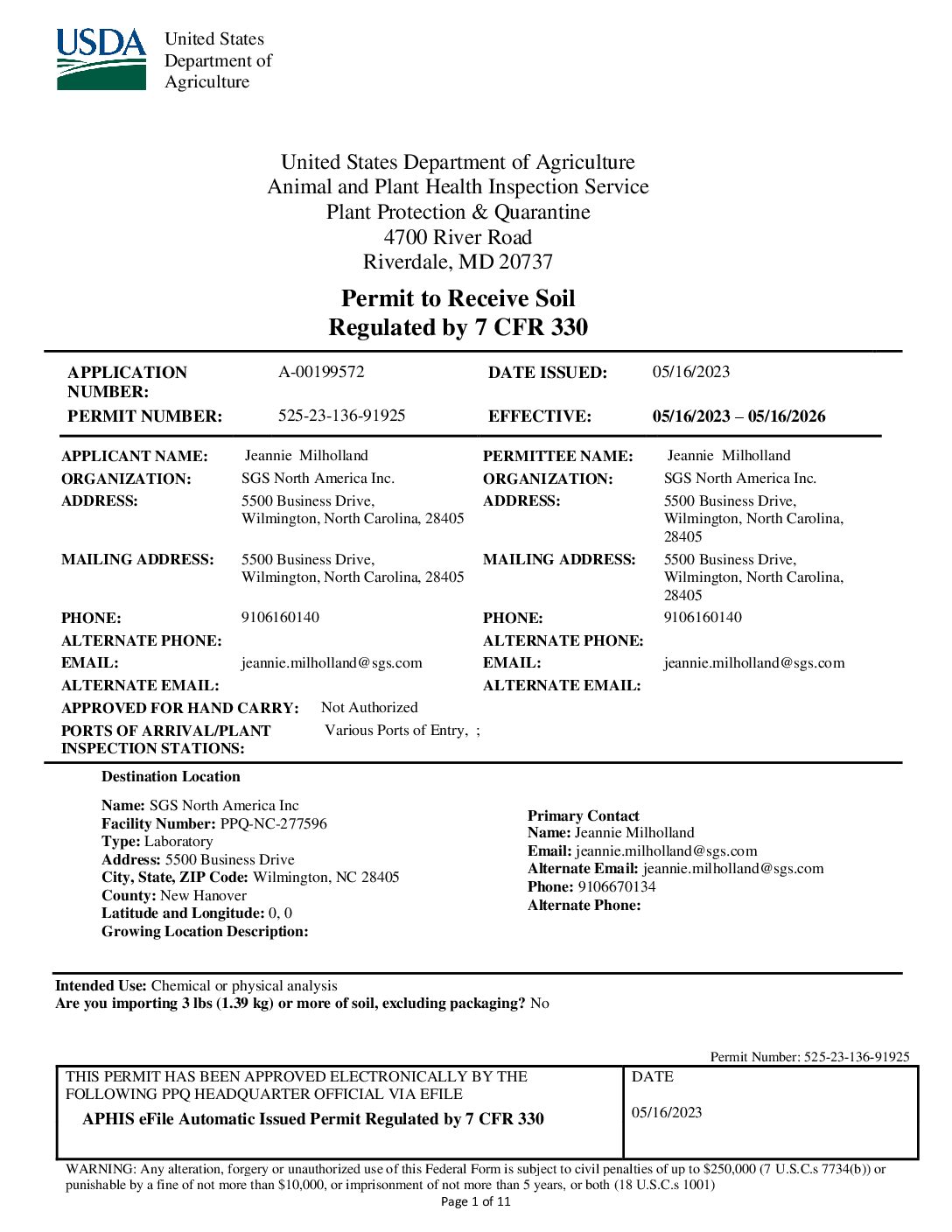

| Wilmington, NC | SGS Wilmington USDA | Foreign Soil | USDA | marine-services pfas-analysis ultratrace | not-applicable | wilmington-nc | foreign-soil | usda | ||

| Wilmington, NC | SGS Wilmington US Coast Guard Letter | Other | US Coast Guard | marine-services pfas-analysis ultratrace | not-applicable | wilmington-nc | other | us-coast-guard | ||

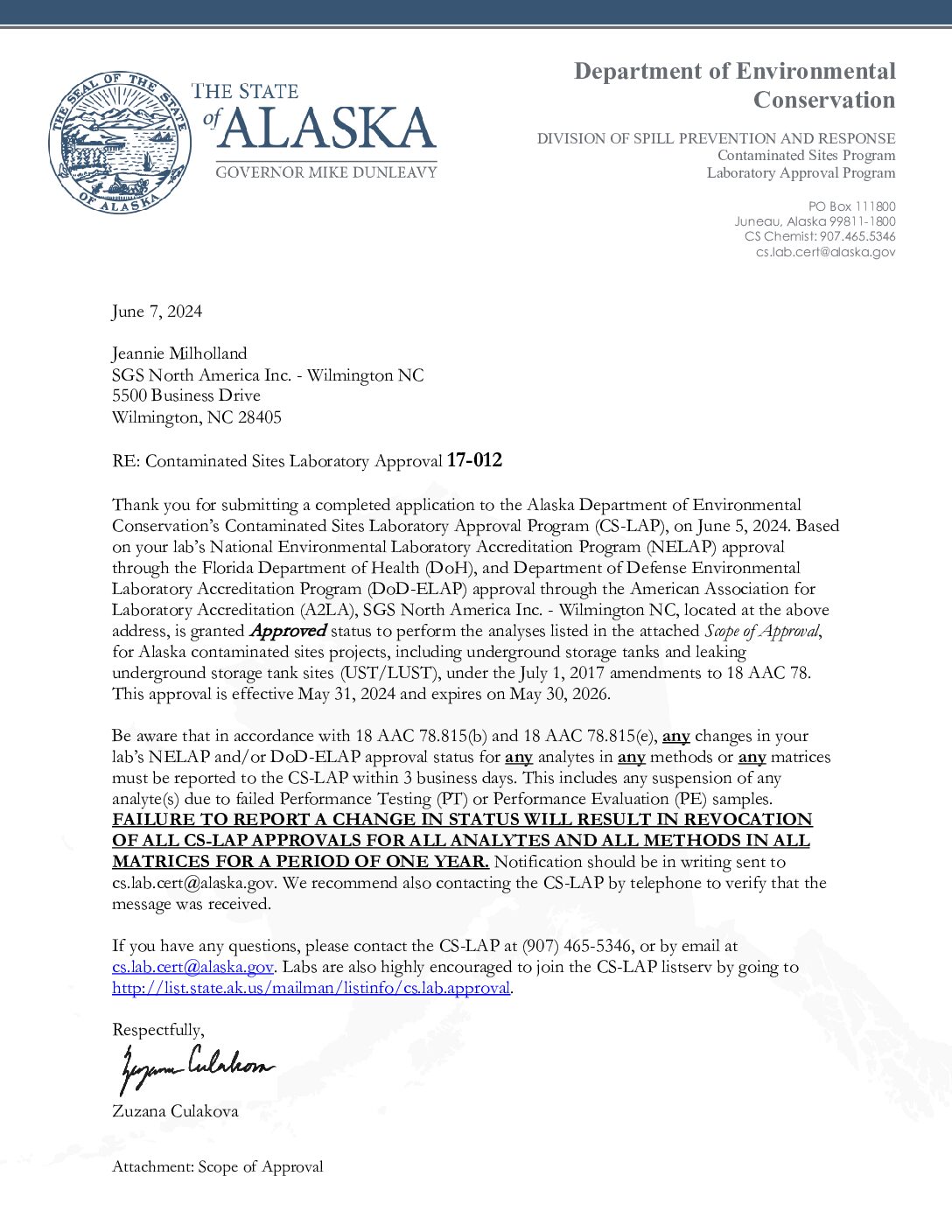

| Wilmington, NC | SGS Wilmington Alaska DEC | Non-NELAP States | Alaska Department of Environmental Conservation (AK DEC) | marine-services pfas-analysis ultratrace | alaska | wilmington-nc | non-nelap-states | alaska-department-of-environmental-conservation-ak-dec | ||

| Wilmington, NC | SGS Wilmington Alaska DW | Drinking Water | Alaska Department of Environmental Conservation (AK DEC) | marine-services pfas-analysis ultratrace | alaska | wilmington-nc | drinking-water | alaska-department-of-environmental-conservation-ak-dec | ||

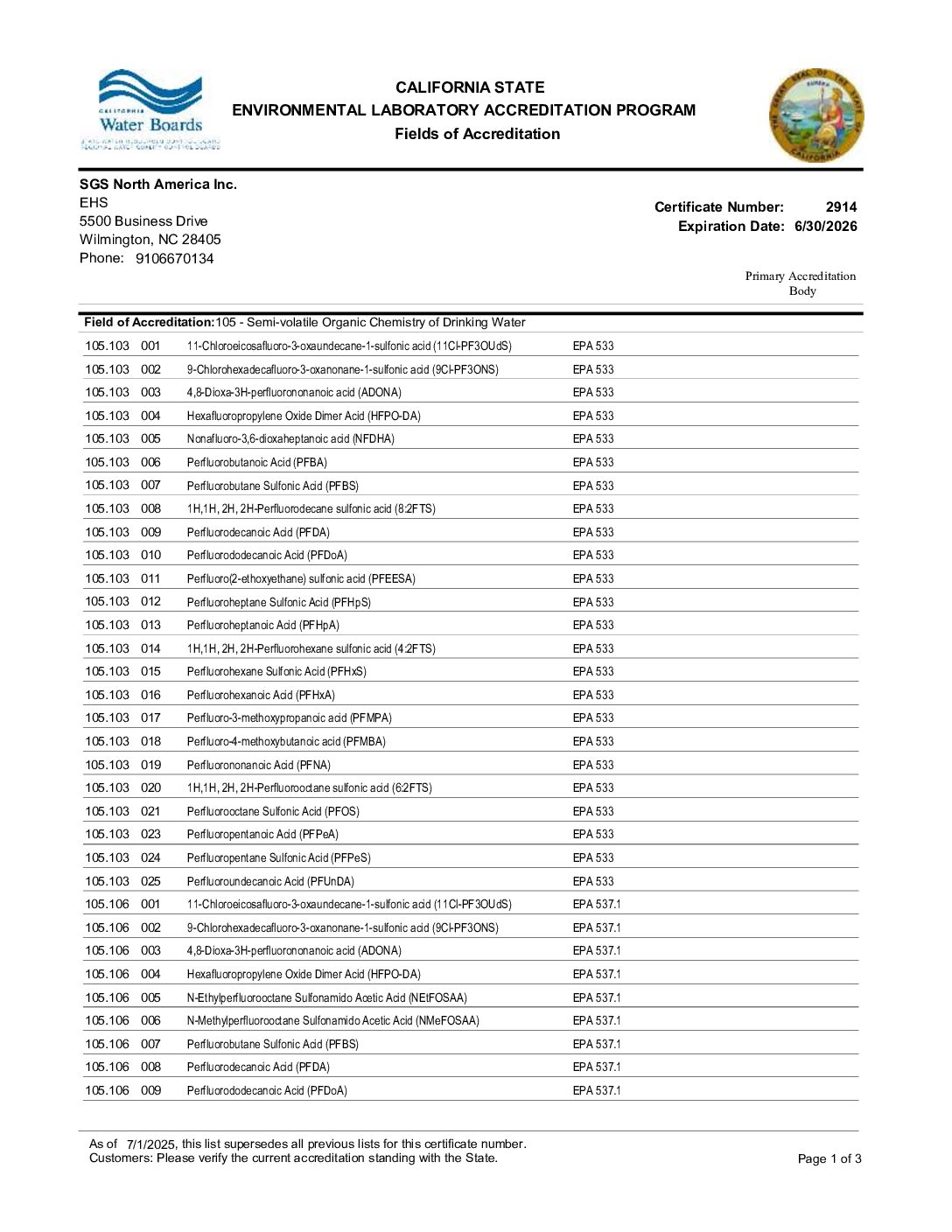

| Wilmington, NC | SGS Wilmington California | TNI - 2 (California) | California Waterboards | marine-services pfas-analysis ultratrace | california | wilmington-nc | tni-2-california | california-waterboards | ||

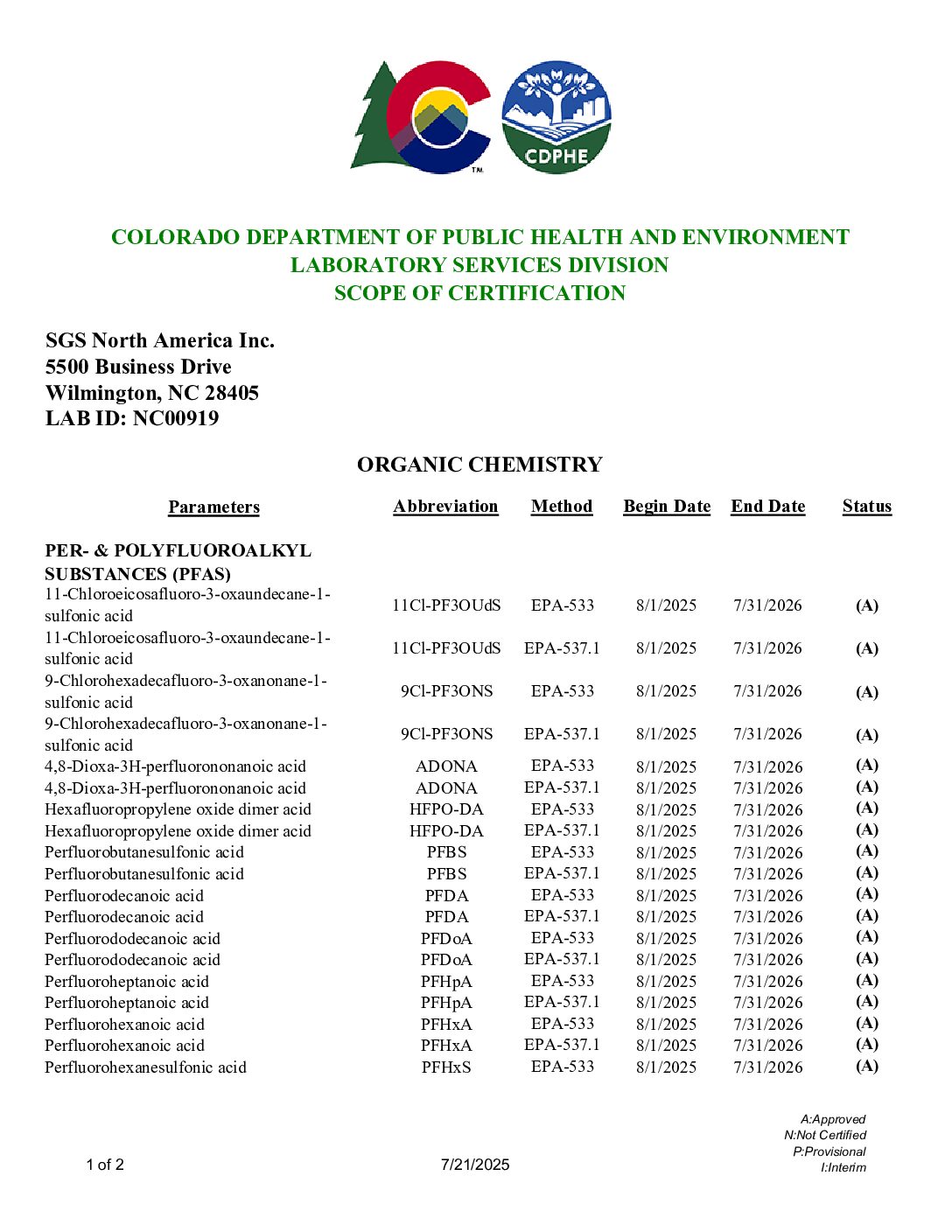

| Wilmington, NC | SGS Wilmington Colorado | Drinking Water | Colorado Department of Public Health and Environment (CODPHE) | marine-services pfas-analysis ultratrace | colorado | wilmington-nc | drinking-water | colorado-department-of-public-health-and-environment-codphe | ||

| Wilmington, NC | SGS Wilmington Connecticut | Non-NELAP States | Connecticut Department of Public Health (CT DPH) | marine-services pfas-analysis ultratrace | connecticut | wilmington-nc | non-nelap-states | connecticut-department-of-public-health-ct-dph | ||

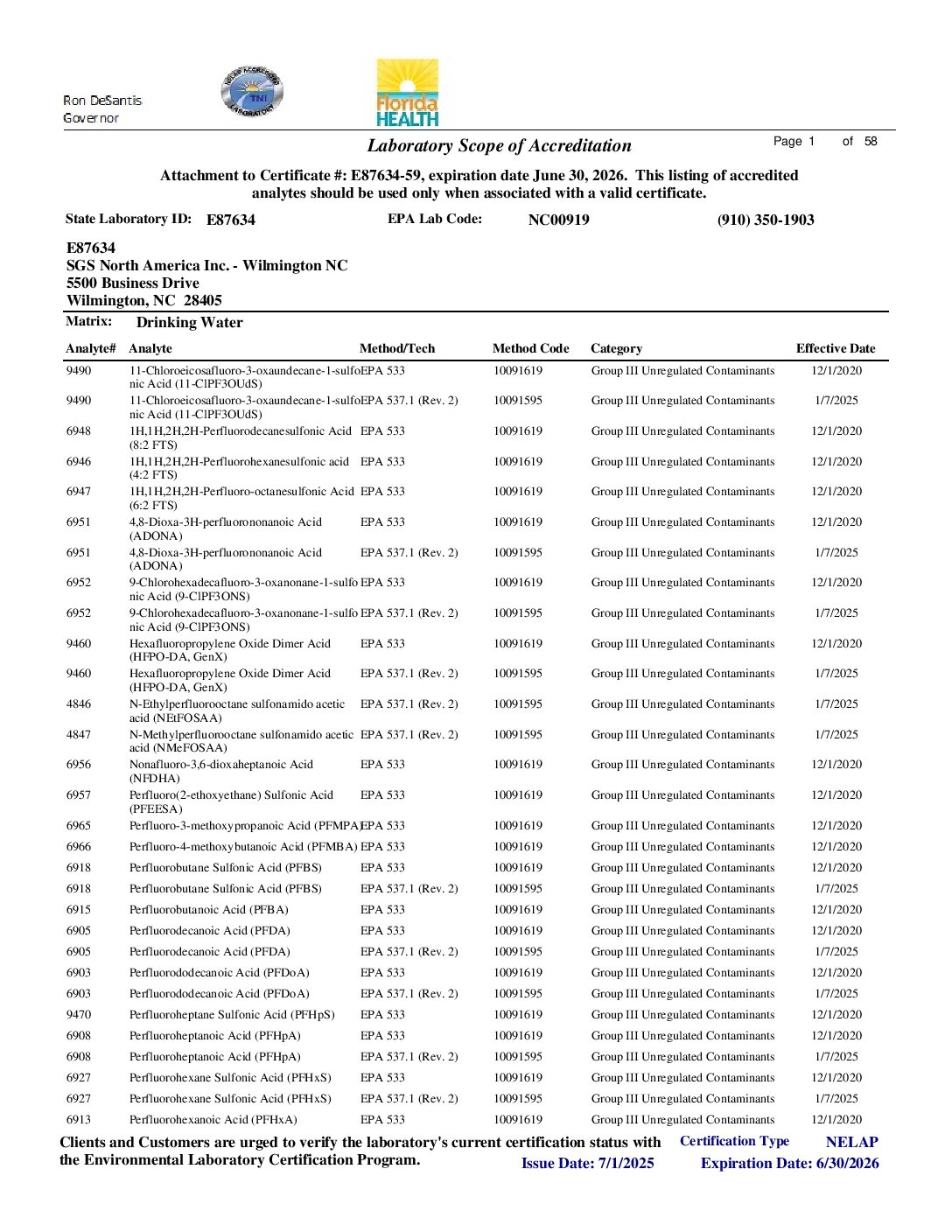

| Wilmington, NC | SGS Wilmington Florida | TNI/NELAP | Florida Department of Health (FL DOH) | marine-services pfas-analysis ultratrace | florida | wilmington-nc | tni-nelap | florida-department-of-health-fl-doh | ||

| Wilmington, NC | SGS Wilmington Louisiana DEQ | TNI/NELAP | Louisiana Department of Environmental Quality (LDEQ) | marine-services pfas-analysis ultratrace | louisiana | wilmington-nc | tni-nelap | louisiana-department-of-environmental-quality-ldeq | ||

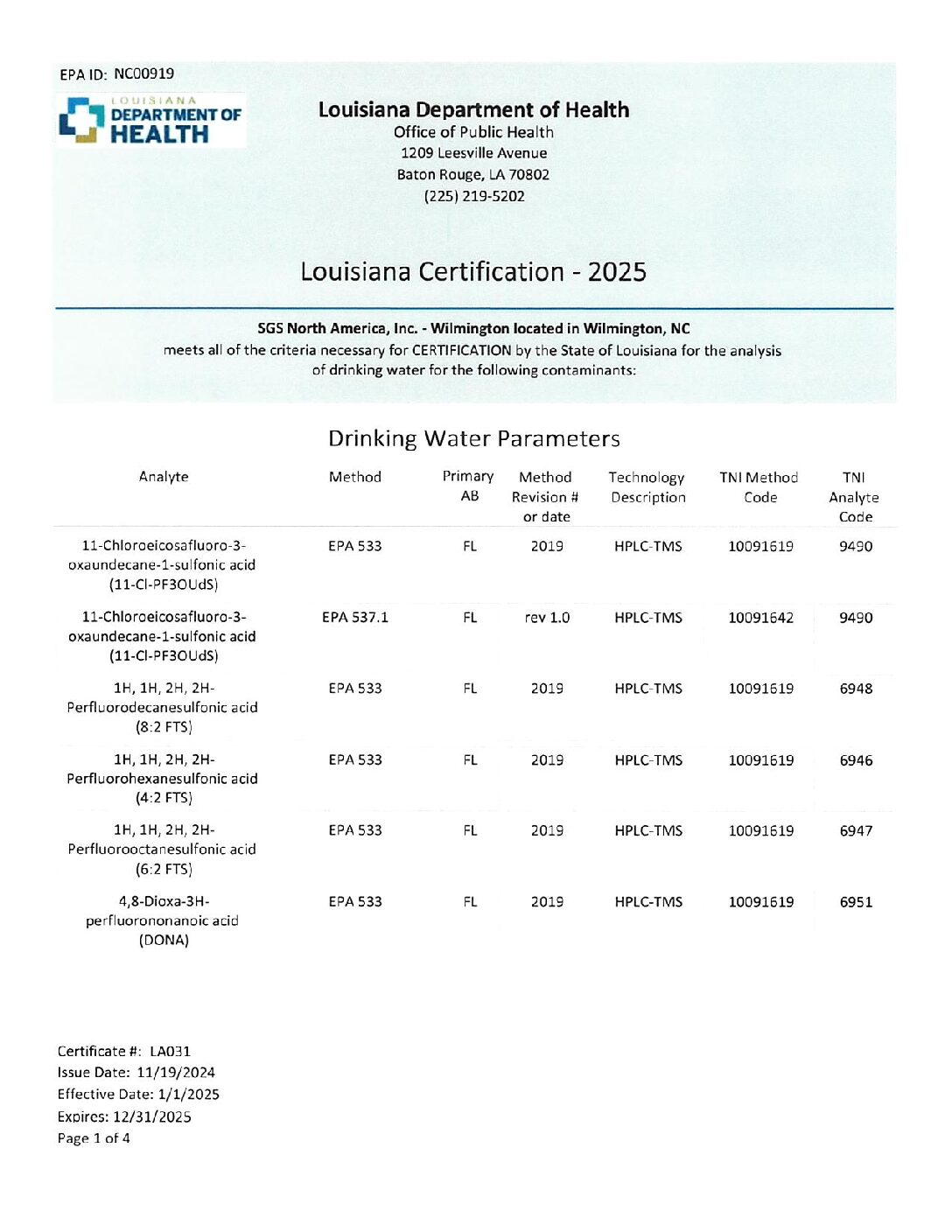

| Wilmington, NC | SGS Wilmington Louisiana DOH | Drinking Water | Louisiana Department of Health (LA DOH) | marine-services pfas-analysis ultratrace | louisiana | wilmington-nc | drinking-water | louisiana-department-of-health-la-doh | ||

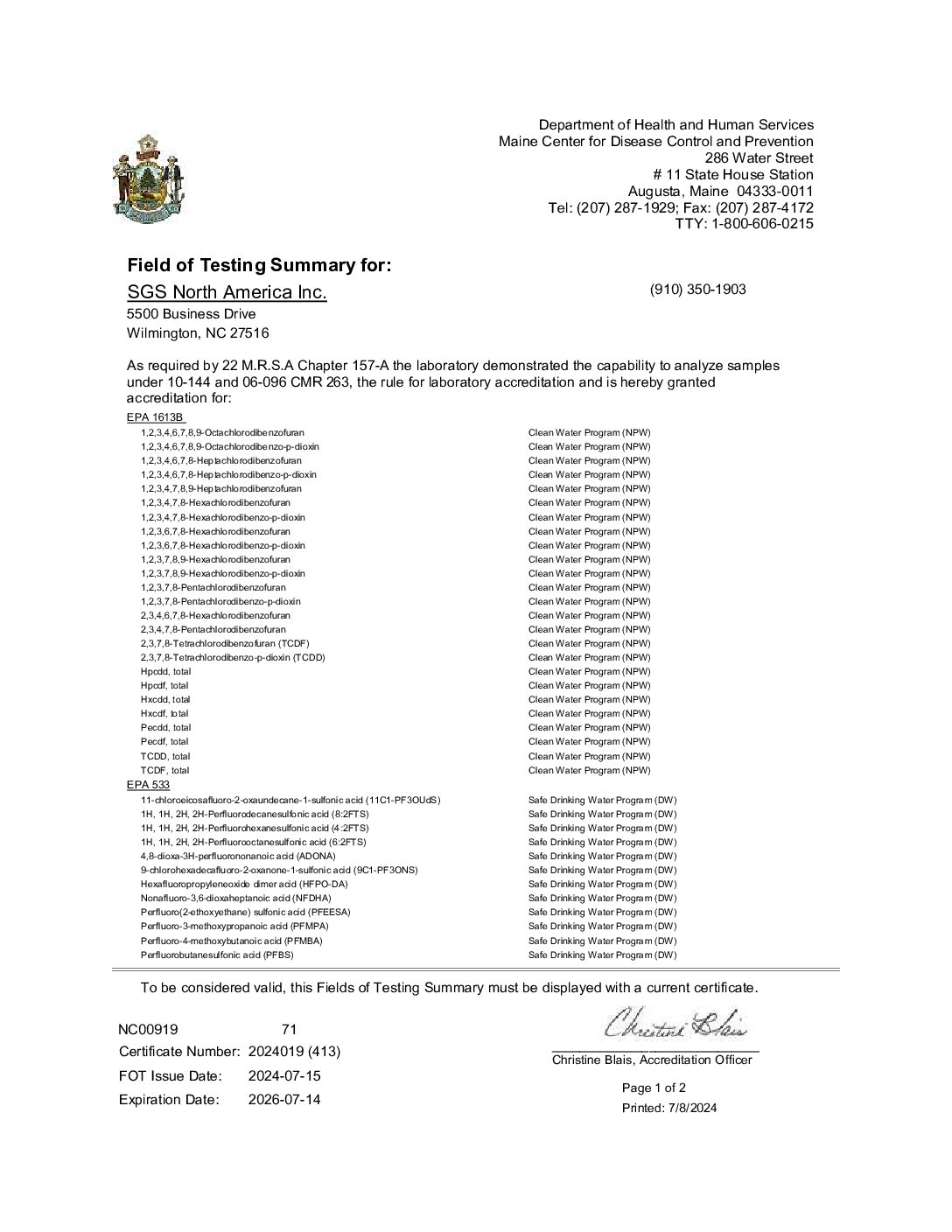

| Wilmington, NC | SGS Wilmington Maine | Non-NELAP States | Maine Laboratory Accreditation Program (ME LAP) | marine-services pfas-analysis ultratrace | maine | wilmington-nc | non-nelap-states | maine-laboratory-accreditation-program-me-lap | ||

| Wilmington, NC | SGS Wilmington Massachusetts | Non-NELAP States | Massachusetts Department of Environmental Protection (MADEP) | marine-services pfas-analysis ultratrace | massachusetts | wilmington-nc | non-nelap-states | massachusetts-department-of-environmental-protection-madep | ||

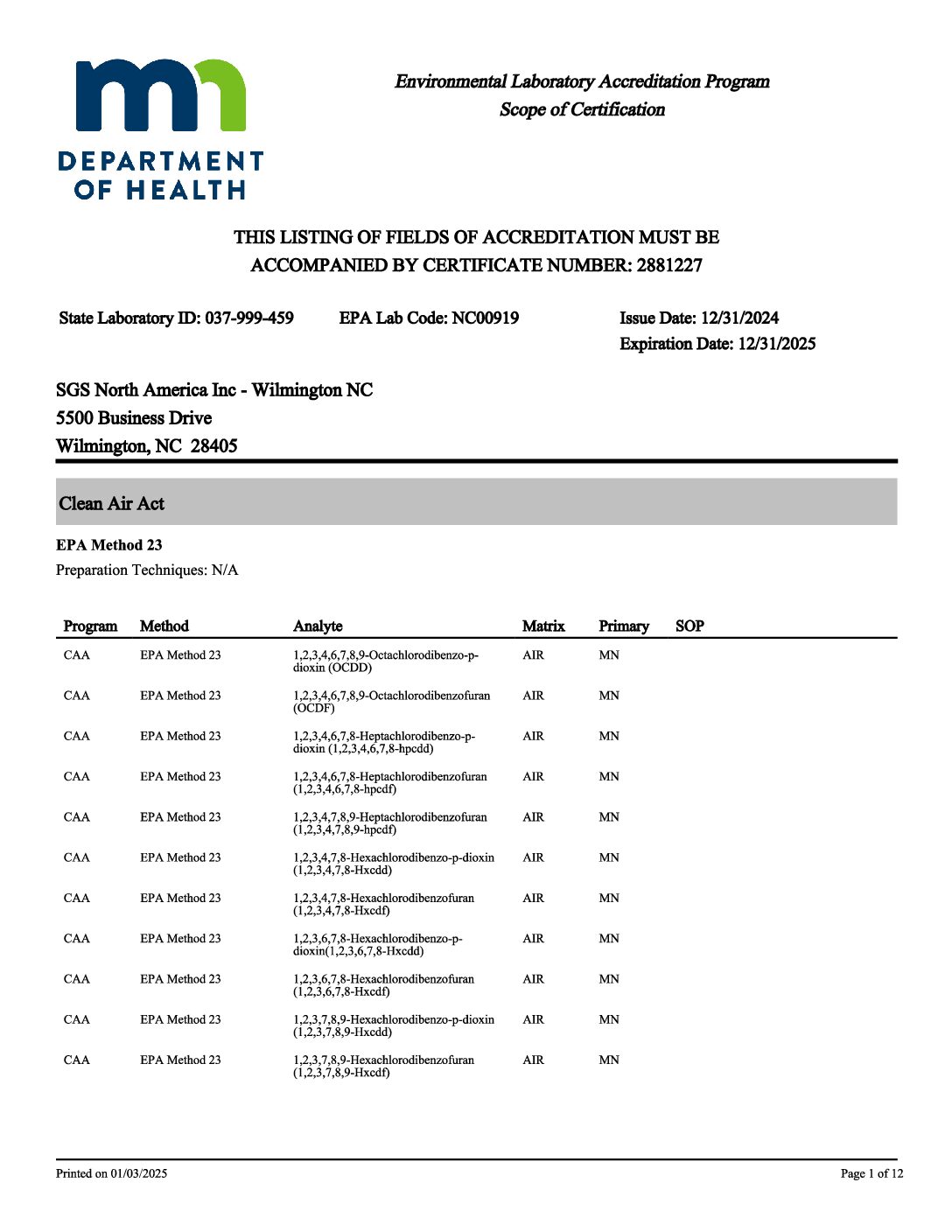

| Wilmington, NC | SGS Wilmington Minnesota DOH | TNI/NELAP | Minnesota Environmental Laboratory Accreditation Program (MN ELAP) | marine-services pfas-analysis ultratrace | minnesota | wilmington-nc | tni-nelap | minnesota-environmental-laboratory-accreditation-program-mn-elap | ||

| Wilmington, NC | SGS Wilmington Montana | Drinking Water | Montana Department of Public Health (MT DPH) | marine-services pfas-analysis ultratrace | montana | wilmington-nc | drinking-water | montana-department-of-public-health-mt-dph | ||

| Wilmington, NC | SGS Wilmington New Hampshire | TNI/NELAP | New Hampshire Environmental Laboratory Accreditation Program (NH ELAP) | marine-services pfas-analysis ultratrace | new-hampshire | wilmington-nc | tni-nelap | new-hampshire-environmental-laboratory-accreditation-program-nh-elap | ||

| Wilmington, NC | SGS Wilmington New Jersey | TNI/NELAP | New Jersey Department of Environmental Protection (NJ DEP) | marine-services pfas-analysis ultratrace | new-jersey | wilmington-nc | tni-nelap | new-jersey-department-of-environmental-protection-nj-dep | ||

| Wilmington, NC | SGS Wilmington New York | TNI/NELAP | New York State Department of Health (NY DOH) | marine-services pfas-analysis ultratrace | new-york | wilmington-nc | tni-nelap | new-york-state-department-of-health-ny-doh | ||

| Wilmington, NC | SGS Wilmington North Carolina | Non-NELAP States | North Carolina Division of Water Resources (NC DWR) | marine-services pfas-analysis ultratrace | wilmington-nc | non-nelap-states | north-carolina-division-of-water-resources-nc-dwr | |||

| Wilmington, NC | SGS Wilmington Ohio | Drinking Water | Ohio Environmental Protection Agency (OH EPA) | marine-services pfas-analysis ultratrace | ohio | wilmington-nc | drinking-water | ohio-environmental-protection-agency-oh-epa | ||

| Wilmington, NC | SGS Wilmington Oklahoma | TNI/NELAP | Oklahoma Department of Environmental Quality (OK DEQ) | marine-services pfas-analysis ultratrace | oklahoma | wilmington-nc | tni-nelap | oklahoma-department-of-environmental-quality-ok-deq | ||

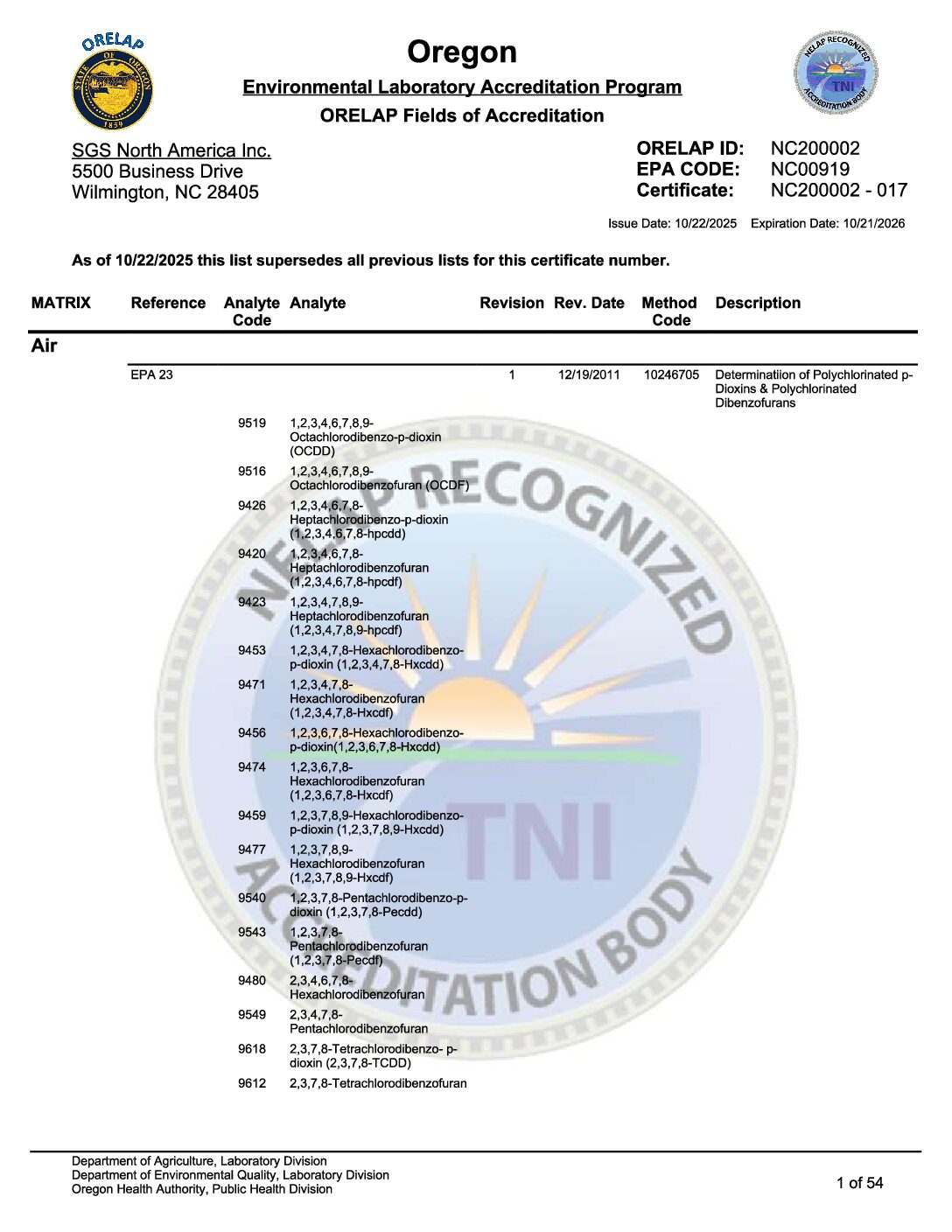

| Wilmington, NC | SGS Wilmington Oregon | TNI/NELAP | Oregon Laboratory Accreditation Program (ORELAP) | marine-services pfas-analysis ultratrace | oregon | wilmington-nc | tni-nelap | oregon-laboratory-accreditation-program-orelap | ||

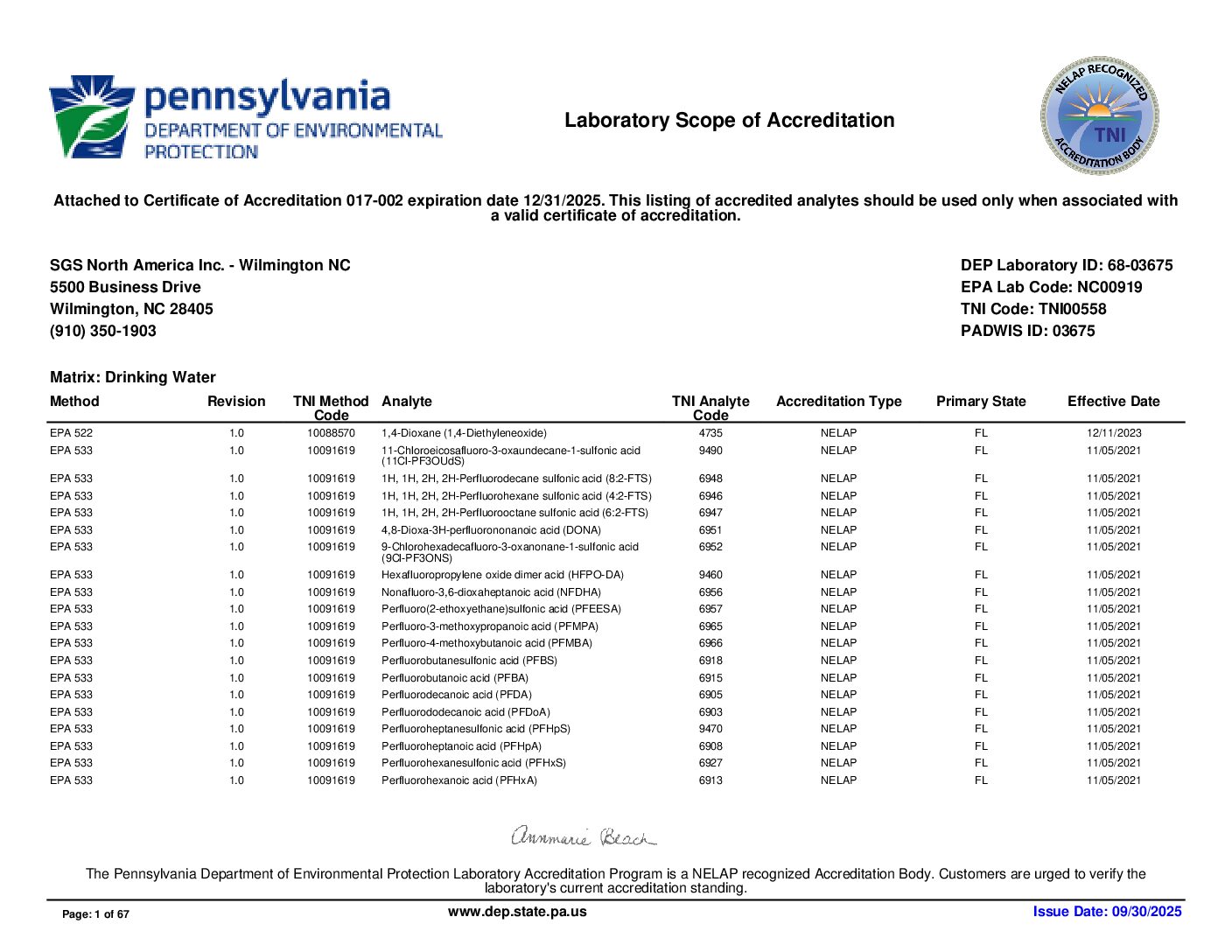

| Wilmington, NC | SGS Wilmington Pennsylvania | TNI/NELAP | Pennsylvania Department of Environmental Protection (PA DEP) | marine-services pfas-analysis ultratrace | pennsylvania | wilmington-nc | tni-nelap | pennsylvania-department-of-environmental-protection-pa-dep | ||

| Wilmington, NC | SGS Wilmington Texas | TNI/NELAP | Texas Commission of Environmental Quality (TCEQ) | marine-services pfas-analysis ultratrace | texas | wilmington-nc | tni-nelap | texas-commission-of-environmental-quality-tceq | ||

| Wilmington, NC | SGS Wilmington Vermont | Non-NELAP States | State of Vermont, Department of Health (VT DOH) | marine-services pfas-analysis ultratrace | vermont | wilmington-nc | non-nelap-states | state-of-vermont-department-of-health-vt-doh | ||

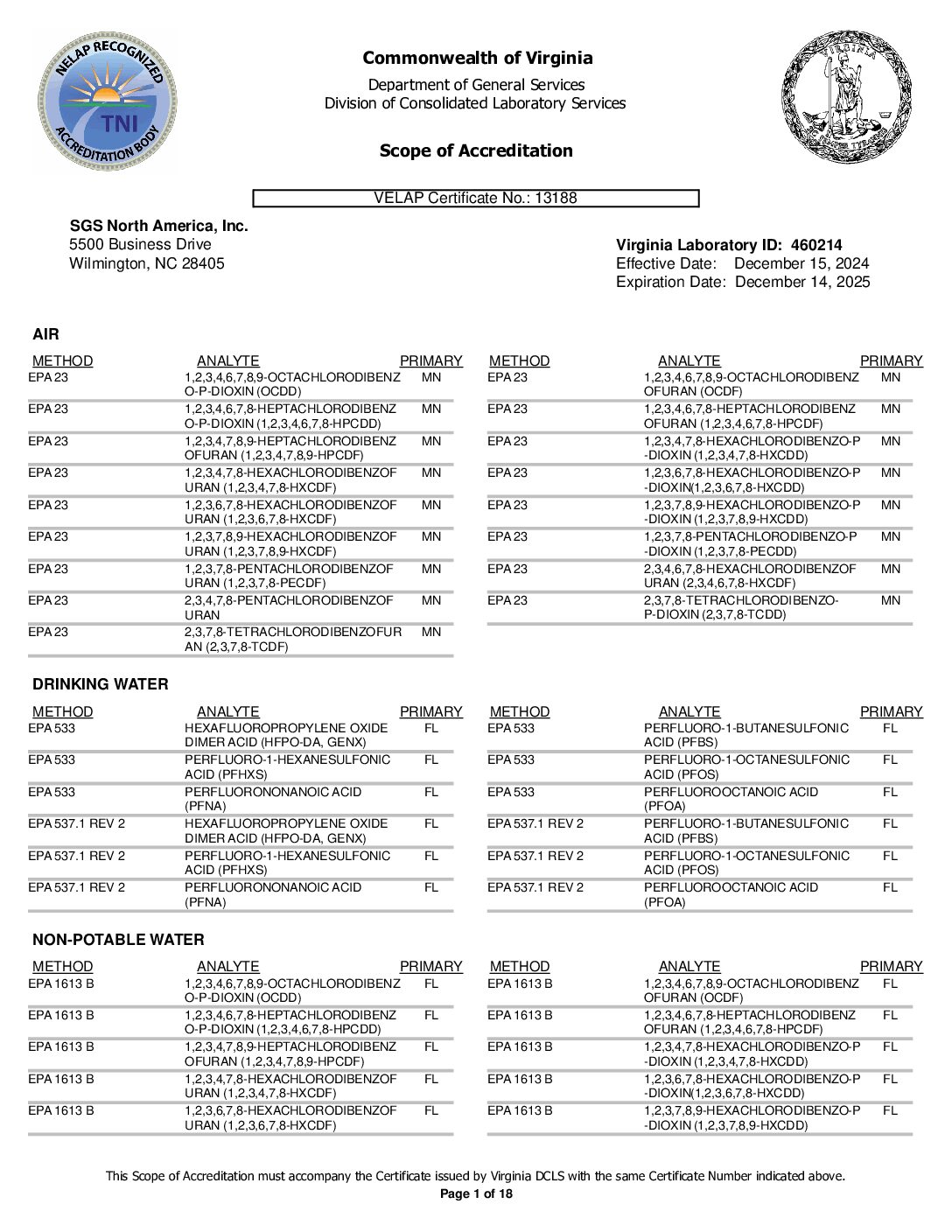

| Wilmington, NC | SGS Wilmington Virginia | TNI/NELAP | Virginia Department of General Services (VA DGS) | marine-services pfas-analysis ultratrace | virginia | wilmington-nc | tni-nelap | virginia-department-of-general-services-va-dgs | ||

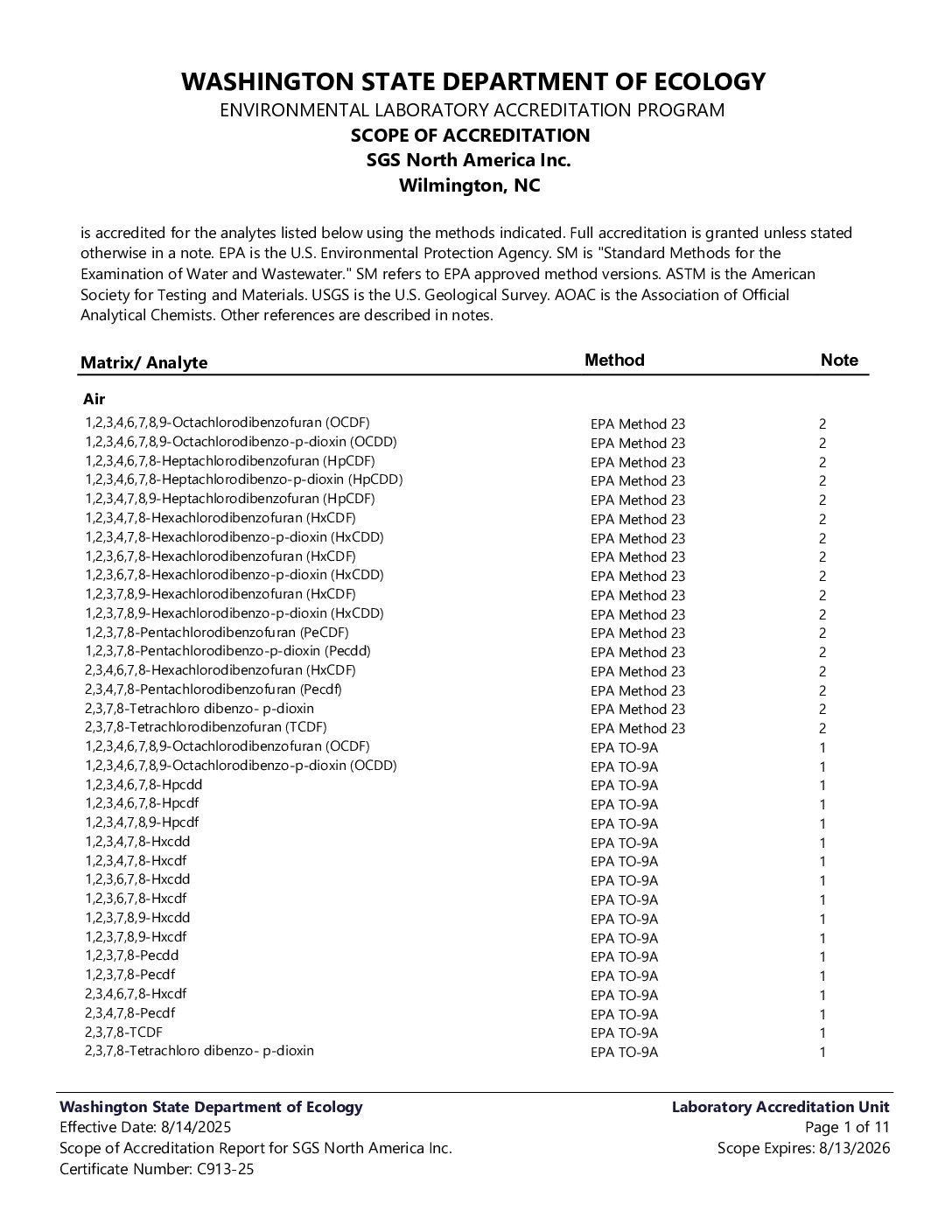

| Wilmington, NC | SGS Wilmington Washington | Non-NELAP States | State of Washington Department of Ecology (WA DOE) | marine-services pfas-analysis ultratrace | washington | wilmington-nc | non-nelap-states | state-of-washington-department-of-ecology-wa-doe | ||

| Orlando, FL | SGS Orlando West Virginia | Non-NELAP States | West Virginia Department of Environmental Protection (WV DEP) | environmental-testing pfas-analysis | west-virginia | orlando-fl | non-nelap-states | west-virginia-department-of-environmental-protection-wv-dep | ||

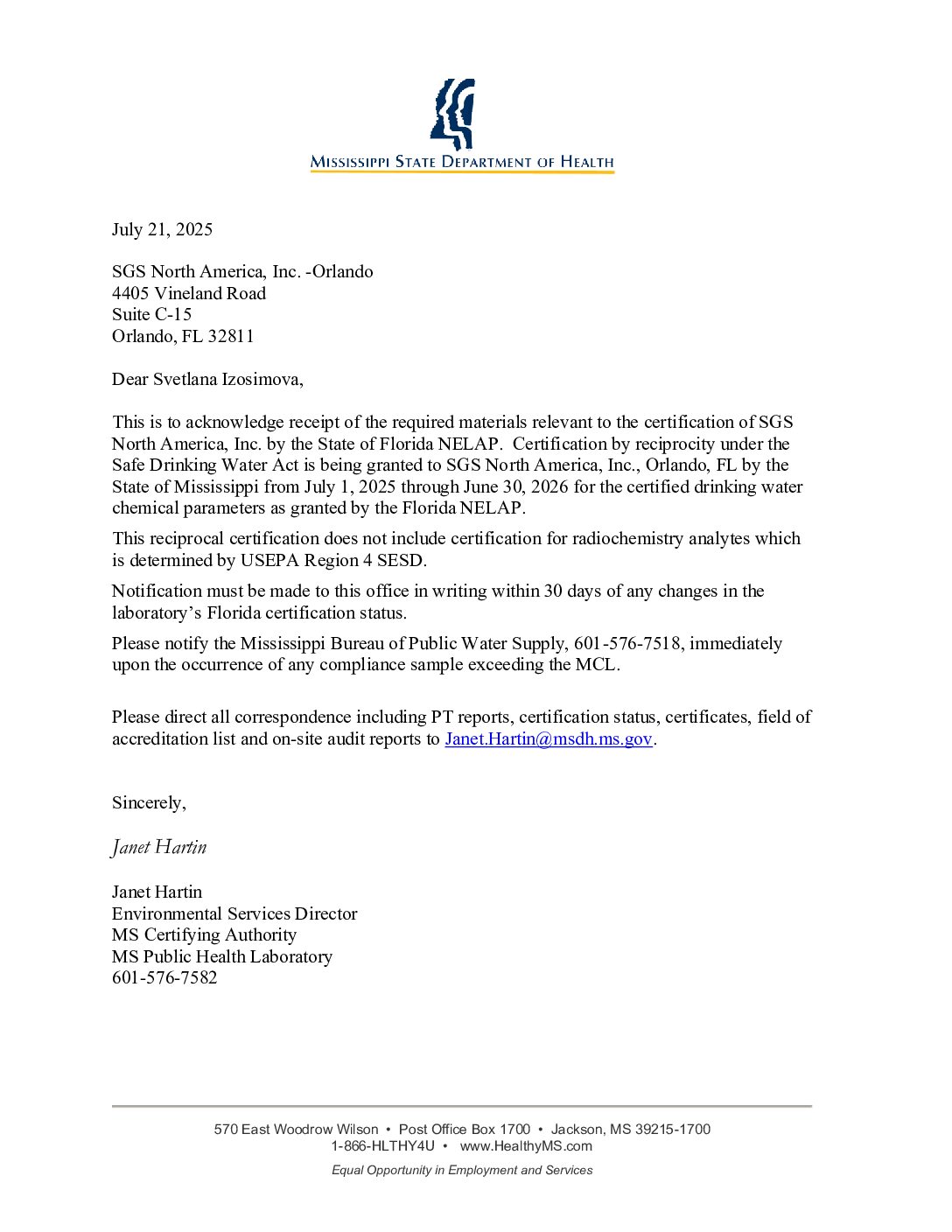

| Orlando, FL | SGS Orlando Mississippi | Drinking Water | Mississippi Department of Health (MS DOH) | environmental-testing pfas-analysis | mississippi | orlando-fl | drinking-water | mississippi-department-of-health-ms-doh | ||

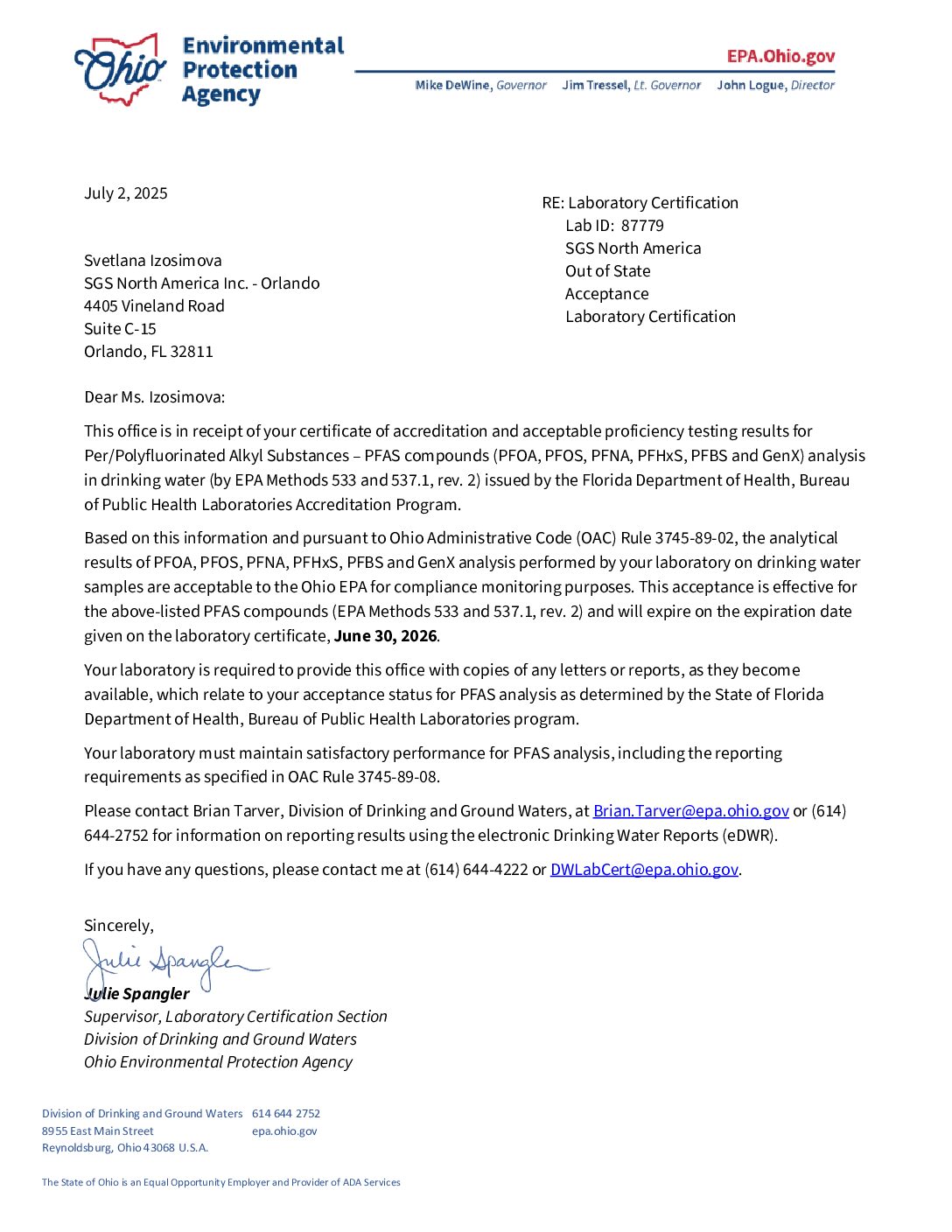

| Orlando, FL | SGS Orlando Ohio | Drinking Water | Ohio Environmental Protection Agency (OH EPA) | environmental-testing pfas-analysis | ohio | orlando-fl | drinking-water | ohio-environmental-protection-agency-oh-epa | ||

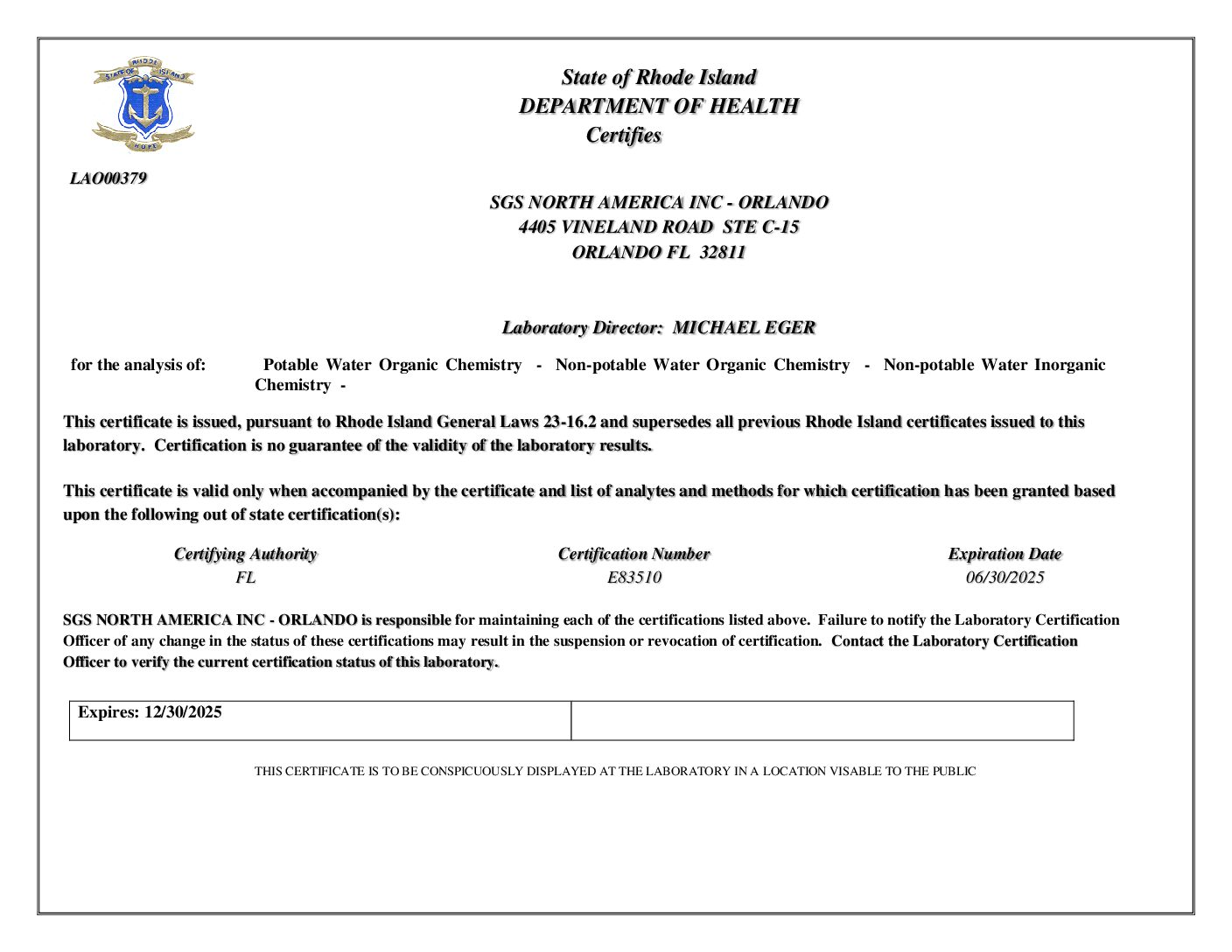

| Orlando, FL | SGS Orlando Rhose Island | Non-NELAP States | Rhode Island Department of Health (RIDOH) | environmental-testing pfas-analysis | rhode-island | orlando-fl | non-nelap-states | rhode-island-department-of-health-ridoh | ||

| Wilmington, NC | SGS Wilmington Michigan | Drinking Water | Michigan Department of Environment, Great Lakes, and Energy (MI EGLE) | marine-services pfas-analysis ultratrace | michigan | wilmington-nc | drinking-water | michigan-department-of-environment-great-lakes-and-energy-mi-egle | ||

| Wilmington, NC | SGS Wilmington South Carolina | Non-NELAP States | South Carolina Environmental Laboratory Certification Program (SC ELCP) | marine-services pfas-analysis ultratrace | south-carolina | wilmington-nc | non-nelap-states | south-carolina-environmental-laboratory-certification-program-sc-elcp | ||

| Houston, TX | SGS Houston Virginia | TNI/NELAP | Virginia Department of General Services (VA DGS) | air-quality | virginia | houston-tx | tni-nelap | virginia-department-of-general-services-va-dgs | ||

| Dayton, NJ | SGS Dayton Kentucky DW | Non-NELAP States | Kentucky Energy and Environment Cabinet (KY EEC) | environmental-testing | kentucky | dayton-nj | non-nelap-states | kentucky-energy-and-environment-cabinet-ky-eec |

Learn more about our accreditations. Read More >